Difference between revisions of "Sustainability"

(→BREEAM) |

|||

| (77 intermediate revisions by 2 users not shown) | |||

| Line 76: | Line 76: | ||

{{#image_template:image=File:B Fig1.png|caption=A fabrication factory for structural steel|align=right|wrap=true|width=300}} | {{#image_template:image=File:B Fig1.png|caption=A fabrication factory for structural steel|align=right|wrap=true|width=300}} | ||

| − | Steel is manufactured by two production routes ([[Steel_manufacture#Basic_oxygen_steelmaking|BOS]] and [[Steel_manufacture#Electric_Arc_Furnace|EAF]]), which together comprise a single global system of supply to meet growing world demand. Both production routes include a significant recycled content, the average of which is 60% for structural steel used in the UK according to WRAP<ref name="no5">[http://www.wrap.org.uk/sites/files/wrap/Rules_of_Thumb1.pdf Calculating and declaring recycled content in construction products. WRAP 2008]</ref> | + | Steel is manufactured by two production routes ([[Steel_manufacture#Basic_oxygen_steelmaking|BOS]] and [[Steel_manufacture#Electric_Arc_Furnace|EAF]]), which together comprise a single global system of supply to meet growing world demand. Both production routes include a significant recycled content, the average of which is 60% for structural steel used in the UK according to WRAP<ref name="no5">[http://www.wrap.org.uk/sites/files/wrap/Rules_of_Thumb1.pdf Calculating and declaring recycled content in construction products. WRAP 2008]</ref>. |

| − | |||

| − | |||

The amount of energy used in steel manufacture has fallen by some 61% since the 1960s, according to World Steel Association data (2020), and further improvements are being sought from steel sector research and development investments. | The amount of energy used in steel manufacture has fallen by some 61% since the 1960s, according to World Steel Association data (2020), and further improvements are being sought from steel sector research and development investments. | ||

| Line 518: | Line 516: | ||

*Giving specifiers and procurement agencies the opportunity to identify key supply chain partners that share a commitment to sustainable construction. | *Giving specifiers and procurement agencies the opportunity to identify key supply chain partners that share a commitment to sustainable construction. | ||

<br> | <br> | ||

| + | |||

| + | ===UK Structural steelwork: 2050 decarbonisation roadmap=== | ||

| + | BCSA developed and published its 2050 decarbonisation roadmap in 2021. | ||

| + | The scope of this roadmap is the UK structural steelwork sector and therefore includes the major steelmakers who supply the UK construction market and the steelwork contractors who design, fabricate, transport and erect steel structures in the UK. | ||

| + | The scope of products within the scope of the roadmap includes:{{#image_template:image=File:Roadmap cover.JPG|align=right|wrap=true|width=200|caption=[[#Resources|BCSA 2050 decarbonisation roadmap]]}} | ||

| + | *Hot-rolled steel sections | ||

| + | *Steel plate | ||

| + | *Structural hollow sections | ||

| + | Although these products are globally traded, currently more than 90% are supplied to the UK market by UK and European producers. This is important because, underpinned by EU and national legislation, most UK and EU steelmakers have already committed to decarbonising steelmaking by 2050. | ||

| + | The roadmap is based on six decarbonisation strategies or ‘levers’ that the sector will concurrently develop and deploy. Absolute carbon reductions attributable to each lever to 2050 are shown. While levers are presented as distinct steps, the transition to net-zero by 2050 will be a complex journey involving a diverse mix of the technologies described below. | ||

| + | The roadmap represents our most likely route as at 2021 based on the current state of development of steelmaking technologies and the various pilot and demonstration studies already underway in the EU and the UK and other planned initiatives, for example relating to reuse. | ||

| + | {{#image_template:image=File:Waterfall.JPG|align=left|width=800|caption=[[#Resources|BCSA 2050 decarbonisation roadmap waterfall]]}} | ||

| + | <br> | ||

| + | BCSA and the wider supply chain, are taking action to deliver this roadmap. Actions undertaken since 2021 or planned, include: | ||

| + | ====Lever 1 Design efficiency==== | ||

| + | Demand reduction through greater design efficiency is an important component of the roadmap both in terms of its contribution and timescale. In the short-term, while new steelmaking technologies are further developed and commercialised, material efficiency gains will deliver early, significant carbon reductions. Demand reduction does not mean fewer steel buildings rather it involves smarter, more efficient design; performing the same structural function but using less steel. | ||

| + | Specific structural steel efficiency measures include:{{#image_template:image=File:SCI P449 cover.JPG|align=right|wrap=true|width=200|caption=[[#Resources|SCI P449]]}} | ||

| + | *Reducing over-specification of structural steel, e.g. more efficient and less conservative design | ||

| + | *Reducing over-specification of design loads | ||

| + | *Reduction of applied loads although it is noted that this may hamper future building flexibility | ||

| + | *Section and profile optimisation that tailors components to their required functionality | ||

| + | *Using higher-strength steel to facilitate the use of lighter members - For example, an S460 grade column weighs 32% less than a standard S355 grade column of the same length and thickness | ||

| + | *Extending building lifetimes, e.g. by designing for adaptability and designing for internal flexibility, for example, by using long spans. | ||

| + | [[#Resources|SCI P449]] provides best practice for designing structurally efficient, low embodied carbon steel buildings. | ||

| + | <br clear=right> | ||

| + | |||

| + | ====Lever 2 Circular economy==== | ||

| + | Steel in general, and structural steel specifically, is truly compatible with circular economic models. To drive optimum resource decision-making, it is important that we look at whole life impacts and the whole life benefits of our buildings and of the components used to construct them. | ||

| + | In the context of this roadmap, the circular economy delivers carbon emission reductions through demand reduction measures relating to extending building lifetimes and preserving the value of steel products through reuse and recycling. | ||

| + | SCI has developed comprehensive guidance on the reuse of structural steel; [[#Resources|SCI P427]] for steel produced from 1970 and [[#Resource|SCI P440]] for steel produced from 1932 to 1970. | ||

| + | These reuse protocols are being widely used to safely facilitate an ever growing number of steel reuse case studies in the UK. | ||

| + | <gallery wrap=true style="float:right;" caption="Structural steel reuse" perrow=2 widths=200px heights=300px> | ||

| + | Image:SCI P427 cover.JPG|SCI P427<Br> | ||

| + | Image:SCI P440 cover.JPG|SCI P440 | ||

| + | </gallery> | ||

| + | |||

| + | ====Lever 3 Direct steelmaking emission reductions==== | ||

| + | Steelmaking emission reduction technologies range from step-change technologies like hydrogen DRI to incremental performance improvements in energy/carbon intensity of specific BF-BOF or EAF processes and include a range of best available technologies, many of which can be retrofitted to existing steel mills. | ||

| + | Several emission reduction technologies have been deployed in many UK and EU steel mills and more are being developed, particularly in the EU. See this interactive Eurofer map. | ||

| + | In the UK, the major steel producers have committed to decarbonise by transitioning from BF-BOF to EAF production. | ||

| + | See [https://britishsteel.co.uk/news/british-steel-decarbonisation-proposals/ British Steel’s decarbonisation proposals] | ||

| + | See also [https://www.tatasteeluk.com/green-steel-future Tata Steel’s green steel transition plans.] | ||

| + | |||

| + | ====Lever 4 Decarbonisation of the UK electricity grid==== | ||

| + | Industrial decarbonisation, including steelmaking, requires clean electricity and so it is critical that the infrastructure is in place to deliver this. Decarbonisation of the UK electricity grid reduces the carbon intensity of both BF-BOF and EAF production. The impact of grid | ||

| + | decarbonisation has a greater influence on scrap-based EAF production because electricity is the primary energy source and can contribute over 50% of the carbon footprint. | ||

| + | It is assumed that by 2050, and probably long before, the UK electricity grid will be almost decarbonised in line with national targets. For example, the UK National Grid estimates that the grid carbon factor (or carbon intensity) will have fallen to 47 gCO<sub>2</sub>/kWh by 2030 (average of all four scenarios); a reduction of 72% compared to 2019 emissions intensity. | ||

| + | The impact of grid decarbonisation on UK steelmaking is also heavily dependent on the transition from BF-BOF to scrap-based EAF steel production | ||

| + | |||

| + | ====Lever 5 Carbon capture and use and storage (CCUS)==== | ||

| + | CCUS refers to a suite of technologies that involves the capture of CO<sub>2</sub> from large point sources, including power generation or industrial facilities that use either fossil fuels or biomass for fuel. If not being used on-site, the captured CO<sub>2</sub> is compressed and transported by pipeline, ship, rail or truck to be used in a range of applications, or injected into deep geological formations (including depleted oil and gas reservoirs or saline formations) which trap the CO<sub>2</sub> for permanent storage. | ||

| + | Both carbon capture and use (CCU) and capture and storage (CCS) will play an important part in the decarbonisation roadmap. Whereas CCS permanently stores captured carbon, CCU converts carbon into commercially viable products such as bio-oils, chemicals, plastics and fuels. These can be used in place of products made from fossil fuels, with the net effect of reducing greenhouse gas emissions. | ||

| + | A key attraction of CCUS technologies is that they can be retrofitted on existing BF-BOF steel plants without significant changes to existing equipment, which makes it easier and lower cost to deploy. | ||

| + | There are several CCUS technologies being developed and trialled in the EU but in the UK, the planned transition to scrap-based EAF steelmaking, has for now, largely eliminated the need for CCUS steelmaking technologies in the UK. | ||

| + | |||

| + | ====Lever 6 Steel transport, fabrication and erection==== | ||

| + | BCSA steelwork contractor members have been measuring and managing their carbon footprint for many years as part of BCSA’s sustainability drive and the introduction of the [[Sustainability#BCSA_Sustainability_Charter|BCSA sustainability charter]] and carbon footprint tools in 2008. The Scope 1 and 2 carbon emissions associated with the fabrication of constructional steelwork come mainly from the energy used in the fabrication shop and associated offices, together with transport of finished products to site, business travel and on-site erection activity. These emissions can be minimized through the increased use of renewable energy, best available fabrication technologies and the use of electric plant and vehicles where possible. | ||

| + | Some steelwork contractors are investing in renewable technologies such as wind turbines, biomass units which produce heat using locally sourced woodchips and anaerobic digestion plants. Some of the technologies used in the fabrication shop include simple ideas such as changing to LED lighting, the use of compressed air leak detection and efficiencies to reduce leaks in compressed air and gas systems, power optimization, inverters to control the speed of electrical drive motors so the speed is increased only when you need it and the use of new generation weld sets. | ||

| + | Many steelwork contractors are also investing in hybrid/electric company vehicles, maintenance vans and electric equipment on-site to reduce emissions. | ||

===BCSA Sustainability charter=== | ===BCSA Sustainability charter=== | ||

| Line 557: | Line 614: | ||

*[[Media:The_whole_story.pdf|The whole story – from cradle to grave]] | *[[Media:The_whole_story.pdf|The whole story – from cradle to grave]] | ||

*[[Media:Target_Zero.pdf|Target Zero – Cost effective routes to carbon reduction]] | *[[Media:Target_Zero.pdf|Target Zero – Cost effective routes to carbon reduction]] | ||

| + | *[https://portal.steel-sci.com/shop.html SCI P427 Structural steel reuse: Assessment, testing and design principles, Second edition, 2024] | ||

*[https://portal.steel-sci.com/shop.html SCI P428 Guidance on Demountable Composite Construction Systems for UK Practice, 2020] | *[https://portal.steel-sci.com/shop.html SCI P428 Guidance on Demountable Composite Construction Systems for UK Practice, 2020] | ||

| + | *[https://portal.steel-sci.com/shop.html SCI P440 Reuse of pre-1970 steelwork, 2023] | ||

*[[Media:BCSA_65-2022.pdf|National Steelwork Specification for Building Construction, Annex J - Sustainability Specification, Publication No. 65/2022, BCSA, 2022]] | *[[Media:BCSA_65-2022.pdf|National Steelwork Specification for Building Construction, Annex J - Sustainability Specification, Publication No. 65/2022, BCSA, 2022]] | ||

*[[Media:BCSA_MS-Reclaimed_Sections.pdf|Model Specification for the Purchase of Reclaimed Steel Sections, BCSA, 2022]] | *[[Media:BCSA_MS-Reclaimed_Sections.pdf|Model Specification for the Purchase of Reclaimed Steel Sections, BCSA, 2022]] | ||

| + | *[[Media:SCI_P449.pdf|SCI P449 Best practice for designing low embodied carbon steel buildings]] | ||

<br> | <br> | ||

[[Target Zero]] design guides: | [[Target Zero]] design guides: | ||

| Line 584: | Line 644: | ||

*[https://www.bcsa.org.uk/ British Constructional Steelwork Association] | *[https://www.bcsa.org.uk/ British Constructional Steelwork Association] | ||

*[http://www.wrap.org.uk Waste Resources Action Programme (WRAP)] | *[http://www.wrap.org.uk Waste Resources Action Programme (WRAP)] | ||

| − | *[https://bregroup.com/about-us/bre-global/ BRE Global] | + | *[https://bregroup.com/about-us-2/bre-global/ BRE Global] |

*[http://www.steel-sci.com Steel Construction Institute] | *[http://www.steel-sci.com Steel Construction Institute] | ||

Latest revision as of 11:27, 21 October 2024

The construction and operation of buildings is responsible for almost half of the UK’s carbon emissions, half of its water consumption, around a third of its landfill waste and a quarter of all raw materials used in the economy. This means that the UK’s sustainable development targets cannot be met without a fundamental change in the way buildings are designed, constructed, operated, deconstructed and reused. National targets for greenhouse gas emission reductions in both the operation and construction of buildings and the drive to a circular economy present a huge challenge to the construction industry – a challenge which the steel construction sector is playing a major part in overcoming.

| An introduction to the sustainability credentials of steel

with contributions from:

|

[top]Sustainable construction – legislation and drivers

Main article:Sustainable construction legislation, regulation and drivers

Sustainable construction is an important part of sustainable development because of its contribution to the UK economy and the significant environmental and social impacts that buildings and other structures play in all our lives. Our quality of life, comfort and security, health and wellbeing and productivity are all linked to our built environment.

Part of the UK’s Industrial Strategy, the Construction Sector Deal[1] was published in 2019. This policy paper sets out an ambitious partnership between government and industry that aims to transform the sector’s productivity through innovative technologies and a more highly skilled workforce.

The Sector Deal builds on Construction 2025[2], published by the government and the Construction Leadership Council (CLC) in 2013, and provides the framework for a sector that delivers:

- a 33% reduction in the cost of construction and the whole life cost of assets

- a 50% reduction in the time taken from inception to completion of new build

- a 50% reduction in greenhouse gas emissions in the built environment –supporting the Industrial Strategy’s Clean Growth Grand Challenge

- a 50% reduction in the trade gap between total exports and total imports of construction products and materials

(LETI Climate emergency design guide[3])

These goals will be met by focusing on 3 strategic areas:

- Digital techniques deployed at all phases of design will deliver better, more certain results during the construction and operation of buildings. Clients, design teams, construction teams and the supply chain working more closely together will improve safety, quality and productivity during construction, optimise performance during the life of the building and better our ability to upgrade and ultimately dismantle and recycle buildings.

- Offsite manufacturing technologies will help to minimise the wastage, inefficiencies and delays that affect onsite construction, and enable production to happen in parallel with site preparation – speeding up construction and reducing disruption.

- Whole life asset performance will shift focus from the costs of construction to the costs of a building across its life cycle, particularly its use of energy. The government will ensure that our modern Industrial Strategy and our significant investments in housing and infrastructure support this change and innovation.

There are many pieces of primary and secondary environmental legislation impacting the construction industry. Much of this legislation is location specific, e.g. relating to flood risk and management, contaminated land, environmental impact assessment, planning, etc. In terms of new, generic, construction, the most significant legislation relates to:

- Greenhouse gas emissions both in the construction and operation of buildings

- Waste reduction, resource efficiency and the circular economy.

Reduction of operational carbon emissions from buildings is the primary sustainable construction driver in the UK. Through the Climate Change Act [4], the Government has set an ambitious and legally binding target to reduce national greenhouse gas emissions by at least 100% by 2050 with an intermediate target of a 68% reduction by 2030 (against a 1990 baseline). In addition, the Energy performance of buildings Directive (EPBD) requires all new buildings to be 'nearly zero energy' by December 2020.

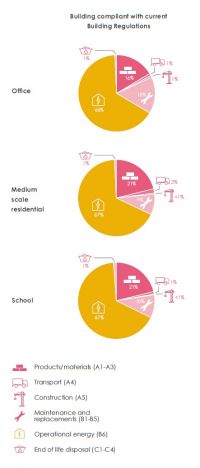

While grid decarbonation over time should reduce operational carbon emissions, as the figure taken from the LETI guide[3] for new non-domestic buildings shows, operational carbon emissions still make up most (around 2/3) of the whole life carbon emissions of a building over 60 years and therefore remains the priority for reduction.

Measures introduced to reduce operational carbon emissions from buildings include:

- Part L of the Building Regulations in England and Wales, Technical Handbooks Section 6 in Scotland and Technical Booklets F1 and F2 in Northern Ireland

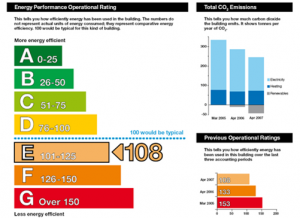

- Energy Performance Certificates (EPCs) introduced as part of its strategy to implement the Energy Performance of Buildings Directive (EPBD). The UK Government introduced Energy Performance Certificates (EPCs) for all commercial and other non-domestic premises greater than 50m2 in April 2008.

First introduced in 2008, Display Energy Certificates (DECs) are required (since 2015) for buildings with a total useful floor area over 250m2 that are occupied by a public authority and frequently visited by the public.

EPCs and DECs are intended to create greater awareness and stimulate demand for more energy efficient buildings.

In the absence stronger policies and regulation by Government, several organisations have published their own strategies and recommendations of how the built environment could achieve the necessary operational carbon reductions to help meet the UK Climate Change Act [4] commitments. These include LETI[3] and RIBA[5] who have set targets and benchmarks for operational energy efficiency in new buildings to meet ‘net zero’ carbon emissions targets by 2050.

Planning also plays an important role in delivering holistic sustainable development. Most planning legislation and guidance is relatively ‘high-level’ and does not generally impact upon the detailed design and construction of buildings. One exception to this is Supplementary Planning Guidance.

Supplementary Planning Guidance (SPG) and Supplementary Planning Documents (SPDs) provides greater detail on the delivery of local development plans. Many local planning authorities have SPG/SPDs relating to the design and construction of sustainable buildings. This guidance can vary dramatically from authority to authority and includes information relating to operational and renewable energy and materials selection criteria, etc. SPG and SPDs are considered in the determination of planning applications.

BREEAM (BRE Environmental Assessment Method) is the leading and most widely used environmental assessment method for buildings. It has become the de facto measure of the environmental performance of UK buildings. Although voluntary, many publicly funded/procured buildings are required to have a minimum BREEAM rating. Many commercial building clients also recognise the benefits of procuring sustainable buildings and are increasingly using BREEAM to deliver sustainable buildings.

The construction and demolition sectors generate more waste in the United Kingdom than any other. They are also the largest producers of hazardous waste. Waste legislation and drivers impacting the construction and demolition practice include:

- The Landfill tax

- The Aggregates Levy

- Site Waste Management Plans

- Waste credits within BREEAM.

The government’s Resources and Waste Strategy (2018) [6] aims ‘to eliminate avoidable waste of all kinds by 2050’ in England; this includes construction and demolition waste. The Green Construction board has published a report on the interpretation of zero avoidable construction waste and work is underway to develop a roadmap setting out how and when this can be achieved.

European Union legislation is also impacting UK construction. Measures particularly influencing construction practice include the Landfill and Waste framework Directives; the Directive on the energy performance of buildings; the Construction Products Regulation and CEN Harmonisation standards which include CEN TC350 standards on the assessment of the sustainability of construction works and the Energy Efficiency Directive. Many of these are implemented in the UK by the national regulations described above. There is also the EU Circular Economy Package which was launched in 2015. This includes revised legislative proposals on waste, and measures to stimulate Europe's transition towards a circular economy which aims to boost global competitiveness, foster sustainable economic growth and generate new jobs.

[top]Steel and sustainable construction

Main articles: Steel manufacture, Fabrication, The case for steel, Health & safety, Recycling and reuse, Steel and the circular economy, Target Zero, Cost of structural steelwork, BREEAM

Steel’s material properties make it the ultimate sustainable construction material both in terms of its material properties and the credentials of steel-framed buildings.

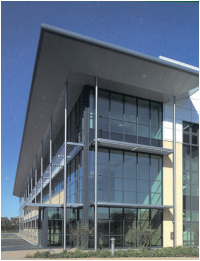

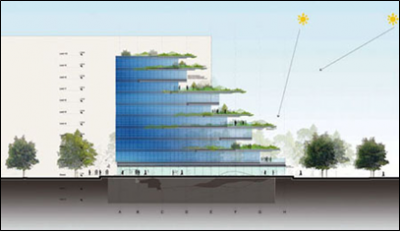

Its superior strength-to-weight ratio means a little steel goes a long way, giving architects complete flexibility to innovate and create new and exciting buildings that are a pleasure to live and work in. Low and zero carbon buildings and buildings with high BREEAM ratings are readily achievable using steel construction. The example shown is the low energy Devonshire Building at Newcastle University, which achieved a BREEAM ‘Excellent’ rating.

[top]Steel manufacture

Manufactured from the most abundant element on earth, iron, steel can be recycled or reused endlessly without detriment to its properties. This unique characteristic gives all steel a high value at all stages of its life cycle. The recovery infrastructure for steel recycling is highly developed and highly efficient, and has been in place for decades. Current recovery rates from demolition sites in the UK are 99% for structural steelwork and 96% (on average) for all steel construction products – figures that far exceed those for any other construction material. Recycling steel is ‘true recycling’ in which scrap steel substitutes primary steel. This is unlike many other construction materials which are ‘downcycled’ into lower grade applications.

Steel is manufactured by two production routes (BOS and EAF), which together comprise a single global system of supply to meet growing world demand. Both production routes include a significant recycled content, the average of which is 60% for structural steel used in the UK according to WRAP[7].

The amount of energy used in steel manufacture has fallen by some 61% since the 1960s, according to World Steel Association data (2020), and further improvements are being sought from steel sector research and development investments.

By-products from iron and steel-making, including sludges, slags and dust, are beneficially used by the construction industry in a range of products including roadstone, lightweight aggregate and as cementitious material used as a substitute for Portland cement. Tata Steel and British Steel, the major steel producers in the UK, recycle or reuse over 90% of their process residues.

[top]Steel fabrication

All steel components are manufactured in the controlled environment of a fabrication factory, where consistent structural elements with assured quality and full traceability can be created to meet the specific requirements of each project. In this environment, steel parts can be easily standardised, tested and certified. Any waste material produced during the fabrication phase, e.g. off-cuts, swarfe, can be recycled and used again in the steelmaking process.

Off-site manufacture is more efficient, faster, leaner and safer than site construction. It also yields high quality products with fewer defects that require less ‘snagging’ on site, leading to savings in both time and money.

Being factory-based, steel production and fabrication requires skilled, settled workers. There is little need or desire for an itinerant workforce, and as such it provides stable employment. Compared to working on-site, the fabrication factory is a far safer environment for workers; and productivity and quality are not subject to the elements to the same degree as site-based construction.

[top]The steel supply chain

The United Kingdom is the world’s leader in steel construction both commercially, technically, and in terms of quality. From humble beginnings over 200 years ago, the industry has gone from strength to strength achieving a current global turnover of £3,000 million and providing employment for over 100,000 people.

The industry has made dramatic improvements in technology, productivity and efficiency, helping it to maintain strong exports of steelwork and related products and services. In the UK market, approximately 95% and 65% of all single-storey industrial buildings and multi-storey non-residential construction respectively (by floor area) are framed in steel.

The steel construction industry operates through an efficient integrated supply chain. There is an extensive choice of steelwork contractors available to specifiers and buyers in terms of size, expertise and capabilities, thus ensuring a competitive tender list.

The British Constructional Steelwork Association (BCSA) is the national organisation for the steelwork contractors in the UK and Ireland. Its Member companies undertake the design, fabrication and erection of steelwork for all forms of construction in building and civil engineering. BCSA operates a number a number of schemes to ensure the competency and quality of its members and the products and services they supply. These include the Register of Qualified Steelwork Contractors for Buildings (RQSC - Buildings) requirements, the Register of Qualified Steelwork Contractors for Bridgeworks (RQSC - Bridgeworks), the Steel Construction Certification Scheme (SCCS), CE marking / UKCA marking, and the Steel Construction Sustainability Charter (SCSC).

Structural steelwork is an engineered product utilising the most modern CAD/CAM products, ensuring a good and accurate fit. 3D and virtual reality models can greatly assist the professional staff in the quality and planning of the product design. BCSA members promote an early involvement in the design process to clearly define the design criteria and give the most cost and speed efficient quality designs over the whole life of the structure.

[top]Health and safety

Industry surveys consistently demonstrate that steel is the safest construction material. Components are fabricated offsite in a safe, controlled factory environment. From here they are delivered to site and erected by a small number of skilled personnel. There is minimal requirement for on-site cutting or adjustment, and no need for the time-consuming and potentially hazardous shuttering and handling operations associated with other construction materials.

[top]Speed of construction

The speed of steel construction has made it the framing material of choice for the UK construction sector. A shorter construction programme reduces disruption and disturbance around the site. Steel is relatively clean and quiet to erect, and requires few site deliveries. Speed of construction delivers an economic benefit too, which is fundamental to sustainable development. The shorter on-site period reduces the cost of preliminaries, reduces the period of financing and delivers buildings that are operational faster – providing a quicker return on investment from rent or sale.

[top]Recycling and reuse

Steel can be reused and recycled repeatedly without ever losing its qualities as a building material. This unique characteristic gives all steel a high economic value at all stages of its life cycle which, unlike some other construction materials, ensures that it is routinely recovered and reused. Consequently, the recovery infrastructure for steel recycling is highly developed, highly efficient, and has been in place for decades. Current recovery rates from demolition sites in the UK are 99% for structural steelwork and 96% for all steel construction products – figures that far exceed those for any other construction material.

Because steel frames are essentially a kit of parts, it is possible that they may be dismantled and reused. Standard section ranges and bolted connections allow components to be removed in prime condition and easily reused either individually or en masse as entire structures. It means that steel components have the potential to be perpetually reused in a continuous loop, and never sent to landfill; a truly circular economic model.

A ProLogis two-storey warehouse and office building at Heathrow is shown which was designed to be easily erected and potentially dismantled. Approximately 80% of the portal frame structure is re-usable, 95% of the floor beams and 100% of the galvanized steel components. Click here for more details.

Entire steel structures can be fully dismantled and reconstructed in a different location in a matter of months, without creating any dust and dirt, and very little noise. Constructing a building from a demounted structure is one of the most sustainable ways of creating a ‘new’ building, benefiting the local community and leaving behind no environmental legacy. An example of such a project is 9 Cambridge Avenue, a warehouse building which was dismantled and re-built elsewhere on Slough Trading Estate to make way for a new road bridge. This is an excellent example of steel contributing to the circular economy.

[top]Adaptability

Significant waste can occur at the end of a building’s life when it has to be demolished and its materials scrapped. Steel-framed buildings are easily adaptable if the configuration of the building needs to change. The ability of steel to span large distances means that steel buildings contain large open-plan spaces which are easily reconfigured with lightweight partition walls. The steel frame itself can be easily adapted, with parts added or taken away, and its light weight means that extra floors can often be added without overloading existing foundations.

Steel structures are commonly used to renovate buildings for example behind retained facades. In this way the historic value, character and resources of the façade are retained and the building structure can be reconfigured to create open, flexible internal space that meets modern client requirements and maximises net lettable floor area.

Kinnaird House was constructed in the early 1920s using Portland stone held in place by an integral steel frame. The client's main criterion for the redevelopment was that the existing character of the building should be maintained while maximising the net lettable floor area.

This was achieved using a shallow floor system, tied to the original steel stanchions, and lightweight concrete on steel decking. The consequential reduction in load carried by the foundations enabled an additional floor to be inserted into the old banking hall area and an extra floor to be added for plant at roof level. The shallow floor construction also allowed an unhindered services zone across each floor plate. The redevelopment of Kinnaird House achieved an excellent BREEAM rating.

- Kinnaird House, London, Architect: Trehearne Architects

Shallow floor system behind the retained facade

[top]Attributes of sustainable buildings

Main articles: The case for steel, Operational carbon, Target Zero, BREEAM, Recycling and reuse

The complexity of sustainable construction and sustainable buildings requires the designer to consider a diverse range of design issues. These can include regulatory compliance, for example Part L of the Building Regulations, national and local planning policy, or specific client requirements, for example achievement of a certain BREEAM rating.

The current focus of addressing the climate change emergency is clearly a priority for the construction industry. However, focusing only on carbon emissions is incompatible with broader sustainable development objectives that include social and economic aspects. Designers focusing solely on carbon reduction should be mindful of the ramifications of their decisions in the context of the broader sustainable development agenda.

Below are listed the fundamentals of sustainable building design that are currently most commonly considered in UK construction projects. This is by no means a comprehensive list and no priority or importance should be inferred from the listings.

[top]Location

Key design issues to consider in relation to the location of the building include:

- Proximity to the public transport network and local amenities

- The opportunity to redevelop brown field sites

- Opportunities to reuse any existing buildings on the site

- Maximising recycling of existing materials on site, for example by using the ICE’s Demolition Protocol

- Site the building and use landscaping to develop a favourable micro climate

- Site the building to enhance the ecological value and biodiversity of the site

- Strike a balance between tempering the wind and using it to promote natural ventilation and/or as a source of renewable energy.

[top]Aesthetic appeal

Often overlooked, the aesthetic appeal of buildings should also be considered. Buildings provide our homes, places of work and leisure and therefore how they look and how they make us feel is important in a social context. Contemporary buildings stimulate and inspire their users.

Buildings with aesthetic appeal are likely to be cherished meaning that they more likely to be longer lived and hence be more sustainable. Buildings that are contemporary, inspiring AND flexible/adaptable to future change are particularly sustainable.

Tools such as the Design Quality Indicators (DQIs) can be used to help ensure good design.

[top]Low impact materials

Buildings consume large amounts of varied materials and therefore it is incumbent upon the designer to use and specify low impact materials. Issues to consider include:

- Specify responsibly sourced materials

- Consider the whole life environmental impacts of construction materials using tools such as life cycle assessment and whole life carbon assessment

- Assess buildings holistically, for example by taking account of the structural efficiency of materials and their recyclability and the impact of the superstructure on the substructure, etc.

- Specify materials with a high recycling potential

- Minimise the use of primary aggregates

- Consider whether Modern Methods or Off site construction offer advantages in terms of speed, waste, quality etc.

- Specify inert and low emissions finishes

- Where possible use prefabricated and standardised components to minimise waste and enable subsequent reuse.

[top]Flexibility and adaptability

The pace of change in all walks of life has never been greater. Changing work patterns, new technologies, changing demographics and new legislation are all putting new and different demands on buildings.

Difficulty in adapting buildings to change often leads to their premature redundancy and subsequent demolition. Even before redundancy, failure or inability to adapt and upgrade buildings can compromise occupant comfort and, in commercial buildings, reduce their productivity.

In times of rapid change, sustainable buildings are buildings that are able to accommodate changes in use and importantly, changes to the heating, cooling, lighting services and IT systems used within them. Sustainable buildings should be flexible to change of use and adaptable to future needs and requirements be they regulatory or market driven.

The useful life of buildings can be extended through the adaptation and reconfiguration of internal space and walls, structural extension and upgrading of the external envelope, etc. In these ways the life cycle costs and environmental impacts are reduced as more value is obtained from the same resources.

To become more sustainable, it is important that buildings can accommodate changing business requirements. By doing so, buildings will last longer and greater value will be extracted from the resources (materials) invested in the buildings, which is a key feature of the circular economy.

There are three principal areas in which buildings can be made more flexible and/or adaptable:

- Structural extension (vertically or horizontally)

- Internal flexibility, i.e. facilitating reconfiguration of internal spaces

- Flexible building services.

[top]Recyclability

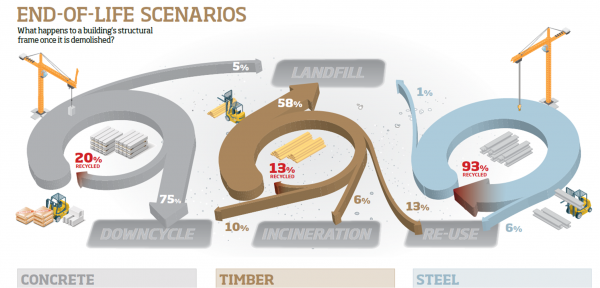

In a resource-constrained world the cost and value of the materials and components used to construct buildings is rising. The traditional end-of-life scenario for buildings was demolition and landfill; however, more attention is now paid to the use of materials that can be reclaimed and recycled when buildings reach the end of their useful life. The characteristics of construction materials vary dramatically in terms of their ability to be recycled. Materials such as metals are truly recyclable, i.e. they can easily be recycled into new products of the same quality and function. Many other construction materials are difficult or uneconomic to recycled and can only be ‘downcycled’ into products of a lower quality or function. A common construction example is concrete which is commonly crushed and reused as general fill or hardcore. Although this is beneficial in that landfill is avoided, it does not replace the need for new resources to make new concrete. These issues are important in the long-term sustainability assessment of construction products.

[top]Demountability and reuseability

Designers should also pay attention to how their buildings can be disassembled at end-of-life so that the opportunities to reclaim, recycle and reuse materials are optimised. So-called ‘design for deconstruction’ can help facilitate greater recycling and reuse of building components.

While this is a relatively new challenge for designers, it is obvious that some construction materials and systems are inherently more demountable and reusable than others. Steel's attributes in terms of recycling and reuse make a significant contribution to the circular economy.

Guidance has been developed by SCI (SCI P428) on the design of demountable composite construction systems so that the structural efficiency benefits of composite construction can be realised and the steel beams (and potentially the floor slabs) can be recovered and reused.

[top]Minimising on-site and local impacts

Inevitably, construction projects impact on local communities. Efforts should be made to reduce and mitigate adverse social and environmental impacts for example by:

- Adopting Site Waste Management plans

- Using the Considerate Constructors scheme

- Monitoring and minimising on site construction impacts including waste, transport, CO2 emissions, productivity, etc.

- Minimising local impacts from construction activities such as traffic congestion, noise and dust.

In addition to specific measures, the choice of construction technology can help minimise local impacts. For example, fast technologies or those based on off-site production can reduce overall construction programmes thereby minimising the duration over which neighbours to building sites are affected.

[top]Operational energy efficiency

The operational energy efficiency (and associated carbon emissions) of buildings has been the focus of most sustainable building design and innovation over recent years. Key design issues include:

- Orientate and space buildings to take advantage of solar gain, natural lighting and any appropriate low and zero carbon technologies

- Incorporate the appropriate amount of thermal mass within the building, ensure that it is exposed and compatible with the ventilation and cooling strategy

- Use glazing, rooflights, etc. to allow solar gain and natural day-lighting

- Provide solar shading to prevent overheating and glare

- Insulate the building well to reduce fabric heat losses

- Incorporate a suitable degree of airtightness

- Consider the integration of appropriate low and zero carbon technologies within or near to the building

- HVAC systems should be selected to match the building’s response and the likely pattern of occupancy

- Use natural or mixed-mode ventilation wherever possible

- Design buildings and services that have the capacity to meet predicted future climate change scenarios

- Provide good controls, sub metering and operating instructions for the building users

- Undertake seasonal commissioning of the building

- Provide appropriate and controllable ventilation to ensure good indoor air quality.

Many of these issues are complex and strongly interrelated and consequently, require expertise including detailed dynamic thermal modelling, to optimise design solutions. Guidance on many issues is provided in the Target Zero design guides.

[top]Robustness and longevity

It is a fundamental of good design that buildings and structures should be safe and robust and that measures to enhance their environmental performance should not compromise this fundamental requirement. Robust buildings are not only safe buildings but should also be durable, last a long time and therefore be inherently sustainable.

It is important that the robustness requirements or classes for different building types are established and that there are proven means of achieving the required robustness.

[top]Low maintenance

Maintenance requirements for some types of building can be high both in terms of cost and environmental impact.

Low maintenance is important in reducing operational costs and can be facilitated by; use of robust forms of construction, efficient, durable protection, and easily maintained servicing and façade systems.

[top]Embodied carbon

Main articles: Recycling and reuse, Life cycle assessment and embodied carbon, Target Zero

Regulatory requirements have, to date, focused on the reduction of operational carbon emissions from buildings, mainly via Part L of the Building Regulations. However, as the operational efficiency of new buildings is improved, the relative significance of the embodied impacts of construction materials and processes increases. In recognition of this, greater attention is being paid to the quantification and reduction of the embodied carbon impacts of buildings and construction products.

The term ‘embodied carbon’ refers to the lifecycle greenhouse gas emissions (expressed as carbon dioxide equivalents – CO2e), that occur during the manufacture and transport of construction materials and components, as well as the construction process itself and end-of-life aspects of the building including demolition, reuse and recycling. CO2e is a measure that describes, for a given mixture and amount of greenhouse gases, the amount of CO2 that would have the same global warming potential (GWP), when measured over a specified timescale (generally, 100 years).

The embodied CO2e and the in-use CO2e emissions resulting from the operation of the building together make up the complete lifecycle carbon footprint of the building. It is recognised that robust carbon assessments should include the whole life cycle of the building.

[top]Embodied carbon assessment

Quantification of the embodied impacts of buildings is more complex than for operational carbon impacts. This is mainly due to different scoping and methodology assumptions, concerning the life cycle stages to be included within the scope of the assessment.

Conceptually, embodied carbon assessments are quite straightforward involving the multiplication of quantities of construction products and materials (generally on a weight basis) with embodied carbon coefficients or carbon emission factors. Quantities are generally derived from a ‘take off’ from construction drawings or directly from Bills of Quantities. Increasingly, design software is being developed to automate the assessment process.

Obtaining a comprehensive and compatible set of embodied carbon coefficients can however be far more difficult. Carbon coefficients are dependent upon a number of factors and assumptions that can significantly influence the final results.

There are several standards that set out how to undertake embodied carbon assessments. These include the ISO 14040 series, standards developed under CEN TC 350, specifically BS EN 15804[8], BS EN 15978[9], etc.

Embodied carbon assessment (also known as carbon foot-printing) is a subset of a full Life cycle assessment (LCA) study, , i.e. addressing one of the typically, 13 environmental impact categories considered in a building LCA study; namely global warming potential. A simplified carbon footprint tool for buildings is available.

[top]Life cycle assessment (LCA)

The most widely used and highly regarded tool for quantifying the environmental impacts of construction and buildings is life cycle assessment (LCA). Despite being conceptually quite straightforward, LCA can be very complex with many important, often material-specific, assumptions than can significantly influence the outcome. LCA is the tool that is used to develop Environmental Product Declarations (EPD) which are increasingly used to quantify the environmental impacts of construction products.

LCA involves the collection and evaluation of quantitative data on the inputs and outputs of material, energy and waste flows associated with a product over its entire life cycle so that its overall environmental impacts can be determined.

An LCA essentially comprises three steps:

- Compiling an inventory of relevant energy and material inputs, e.g. iron ore, and environmental releases, e.g. CO2

- Evaluating the potential impacts associated with identified inputs and releases, e.g. the global warming potential of various greenhouse gases

- Interpreting the results to help make more informed decisions.

An important first step in any LCA is to define the goal and scope of the study clearly. The goal and scope of the study will help define key details of the study including:

- The functional unit of the product to be assessed, e.g. 1 tonne of structural steel or 1 m2 of external wall, etc.

- The system boundaries

- Any assumptions and limitations

- The allocation methods used to partition or share the environmental load of a process when several products or functions share the same process

- The impact categories chosen.

In the context of building and construction LCA, the standards developed by CEN TC 350 are very important in defining how the environmental impacts of construction products and buildings are assessed and reported and are intended to ensure that they are done on a fair and consistent basis throughout the EU. For example, EN 15978[9] are the core standards on which UK embodied carbon assessment guidance produced by RICS and the IStructE are based.

[top]LCA system boundaries

The system boundaries of an LCA study determine which unit processes are included in the scope of the study. Different systems boundaries that can be considered and should be defined include:

- Geographical area, e.g. UK, EU, World, etc.

- Time horizon, i.e. when the data were collected

- Boundaries between the specific system studied and related technical systems, for example, production of capital goods to manufacture a product

- Boundaries between the technological system and nature, i.e. which life cycle stages are included within the system boundary. Common examples include ‘cradle-to-gate’ and ‘cradle-to-cradle’ system boundaries.

It is important when undertaking LCA and embodied carbon assessments that the system boundaries are clearly defined and, when comparative assessments are undertaken, the data used are consistent in terms of the scope and boundaries defined above. This is a common failing of many comparative LCA and embodied carbon studies.

[top]Accounting for end-of-life and recycling

In the context of buildings, because of the significant waste and environmental impact caused when buildings are demolished, it is recognised that a thorough LCA (or embodied carbon) study should consider the full life cycle of buildings including the end-of-life impacts of demolition and the reuse and recycling of demolition materials.

For many construction products, there is a lack of data on the impacts after they have left the factory gate. Consequently many LCA and embodied carbon studies are currently limited to ‘cradle-to-gate’ studies which exclude all subsequent impacts including transport to site, construction activity (and waste) on site, maintenance and end-of-life impacts including demolition and the benefits of recycling and reuse. This can be very significant since, as shown, the end-of-life outcomes of construction materials can be very different. These important differences are not accounted for in ‘cradle-to-gate’ studies.

The Bath ICE database[10], which is widely used in the UK, is a ‘cradle to gate’ study.

It is noted that BS EN 15804[8], the European standard for generating EPD of construction materials, now mandates the reporting of Modules C and D relating to the end-of-life of buildings. This is in recognition of the importance of the circular economy and the need to recycle and reuse construction materials more and better. Module C captures the environmental impacts of demolition, waste treatment and disposal and Module D quantifies the environmental benefits or loads resulting from reusable or recyclable materials

BS EN 15804[8] includes, in Annex D, end-of-life formulae for calculating the environmental impacts and benefits within Modules C and D.

To calculate the environmental impacts of steel manufacturing, the World Steel Association adopts the ‘closed loop recycling’ method of lifecycle assessment, which is the preferred approach under the ISO 14040 series of environmental standards. This approach considers all new steel to be part of single global system of supply and demand and credits can be taken now for future recycling.

As an alternative, bauforumstahl, the independent steel promotional organisation in Germany published an EPD in 2018 based on data collected from the biggest hot rolled steel sections and plates manufacturers in Europe. This 'European EPD'[11] includes the most up to date embodied carbon data currently available steel sections and plates on the European market and is based on the Module D approach from BS EN 15804[8].

[top]Embodied carbon comparisons

Increasingly, clients and their professional advisers include embodied carbon comparisons as part of their overall building design decision-making. It is important that any comparisons are made on a fair and consistent basis, for example, comparing embodied carbon on a unit weight or volume basis can prove misleading. It is important therefore that construction products and systems are compared on a functionally equivalent basis, e.g. 1m2 of external wall construction to satisfy the current Building Regulations and provide a U-value of 0.25 W/m2K.

In fact, it is preferable to compare whole buildings since some choices can have a significant knock-on effect; this aspect can be missed if comparisons are made on just an elemental basis. For example, a light superstructure can mean far fewer foundations are required.

The Target Zero programme included one of the most comprehensive embodied carbon studies. Focussing on the structural frame, the studies compared the embodied carbon impact of five real commercial buildings. Key conclusions from these studies include:

- Based on the buildings studied, operational carbon emissions are not significantly affected by structural form

- For low-rise buildings, the overall embodied carbon impact is dominated by the foundations, ground floor slab and external works

- For medium to high-rise buildings, the embodied carbon impact is dominated by the frame and upper floors

- Based on the buildings studied, optimised structural steel solutions yielded the lowest cost and lowest embodied carbon compared to the alternative structural options considered.

Embodied carbon results can be shared and compared with other studies on the RICS Building Carbon Database which was developed by WRAP and has been taken over by RICS]. Users can upload their embodied carbon assessment results to the database and compare their results with others in the database.

[top]Steel embodied carbon and LCA data

In 1996, worldsteel launched its worldwide life cycle inventory (LCI) study for steel products. This was the first time that such an international study of a specific material had been carried out. The study is regularly repeated and updated and is in accordance with the BS EN ISO 14040[12] series of environmental standards and, more recently, to CEN TC350 standards. The closed-loop recycling method from BS EN ISO 14044[13] is used to account for the benefits of steel recycling.

The worldsteel LCA data have been used in many LCAs; around 200 requests for data are made each year from LCA practitioners and academics around the world. LCAs are used for benchmarking performance, improving products, addressing legislative requirements and assessing competition between materials. Requests for worldsteel LCA data can be made by filling in the online questionnaire to describe how the data are to be used. The request is then discussed with the worldsteel LCA Manager.

Designers and specifiers can use the appropriate steel manufacturer’s Environmental Product Declaration (EPD), assuming that they know where their steel product will be sourced from.

However, if the source of steel product is unknown, which is generally the case at the design stage, then it is recommended that an average value, reflecting a UK average consumption mix is used. This is because steel is a globally-traded commodity and therefore taking, for example, a UK average production value, is not representative of UK consumption.

The BCSA recommends the following UK average emissions factors for embodied carbon assessments of structural steelwork:

| Product | BS EN 15804[8] Modules | Whole Life Carbon | |

|---|---|---|---|

| Product stage | Recycling potential | ||

| Modules A1 to A3 | Module D | ||

| Structural steelwork | 1.74 | -0.93 | 0.81 |

EN 15804[8] states that the figures for the various modules should generally be reported separately, but offers no guidance on how to use the data to make decisions on a project. If decisions are made on a short-term cradle-to-gate or ‘product stage’ basis, then the figure of 1.74 would be used. However, if a more comprehensive long-term Whole Life Carbon basis is adopted, then the figure of 0.81 could be used, which is an aggregate of the tabulated modules A and D.

[top]Operational carbon

Main articles: Operational carbon, Target Zero, Thermal mass

In the drive to reduce national greenhouse gas emissions, significant steps have been taken over recent years to reduce the carbon emissions associated with the use of buildings, principally, in England and Wales, via Part L of the UK Building Regulations.

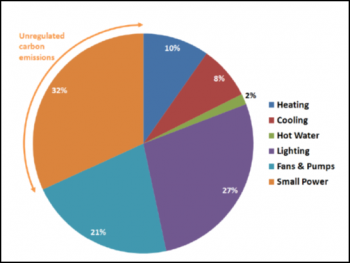

Operational carbon is the term used to describe the emissions of greenhouse gases during the operational phase of a building. In the context of Part L however, only CO2 (rather than CO2e) emissions are currently accounted for. Emissions arise from energy consuming activities including heating, cooling, ventilation and lighting of the building, so called ‘regulated’ emissions, and other, currently ‘unregulated’ emissions, including appliance use and small power plug loads such as IT. These appliances are not currently regulated because building designers generally have no control over their specification and use and they are likely to be changed every few years.

[top]Operational carbon targets

Approved Document L is the mechanism by which operational carbon emissions are regulated in buildings in England and Wales and has a key role to play in defining suitable intermediate steps on the trajectory towards zero carbon buildings.

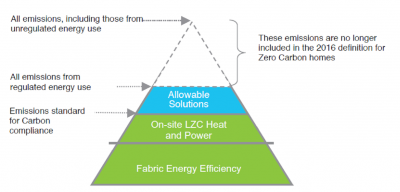

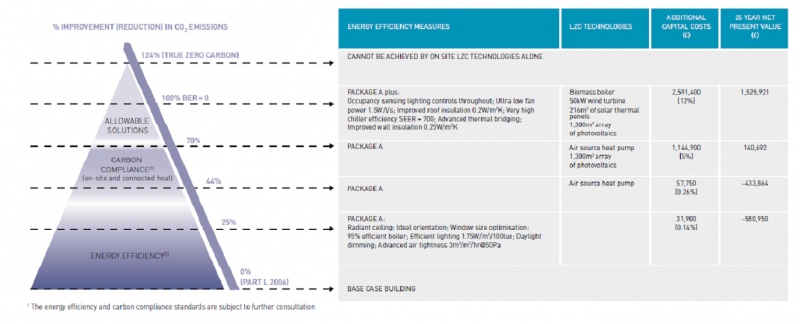

In 2007, UK Government announced its aspiration for new non-domestic buildings to be zero carbon in operation by 2019. Between 2007 and 2010, Government consulted on the definition of ‘zero carbon’ for non-domestic buildings. As a minimum, Government stated that the zero-carbon destination for non-domestic buildings will cover 100% of regulated emissions, i.e. a Building Emissions Rate (BER) of zero. At this time, the Government supported a hierarchical approach to meeting a zero carbon standard for buildings, as shown.

The approach prioritised, in turn:

- Energy efficiency measures - to ensure that buildings are constructed to very high standards of fabric energy efficiency and use efficient heating, cooling, ventilation and lighting systems.

- Carbon compliance on or near site. This is the minimum level of carbon abatement required using energy efficiency measures plus on-site Low and Zero Carbon Technologies (LZC) and/or directly connected heat or coolth.

- Allowable Solutions – a range of additional beneficial measures to offset ‘residual emissions’, for example exporting low carbon or renewable heat to neighbouring developments or investing in community heating.

In July 2015, the UK Government announced that, as part of its Productivity Plan, the zero carbon buildings policy was to be dropped to reduce regulation on house builders. In particular, government stated that it ‘does not intend to proceed with the zero carbon Allowable Solutions carbon offsetting scheme, or the proposed 2016 increase in on-site energy efficiency standards.’

This effectively meant that the 2016 zero carbon homes target were to be dropped, as were the 2019 target for non-domestic zero carbon buildings. It also meant that there were to be no further changes to Part L in 2016. This was confirmed when the Housing and Planning Bill received royal assent in May 2016.

The UK Government’s Construction 2025[15] strategy, published in 2013, set a target of a 50% reduction in GHG emissions in the built environment, by 2025, from a 1990 baseline (in line with the fourth carbon budget under the Climate Change Act).

Through the Clean Growth Grand Challenge, launched in 2019, the government has set out its determination to maximise the advantages for UK industry from this global shift to clean growth, including the mission to halve the energy use of new buildings by 2030.

The 2019 Construction Sector Deal[1] also included the target to reduce greenhouse gas emissions in the built environment by 50%.

Despite these high-level commitments there have been few policy or regulatory changes to drive operational carbon reductions from buildings.

The Committee on Climate Change, in their latest (2020) progress report to Government, are critical of the delay in implementing policy changes in buildings and construction that are likely to deliver greenhouse gas emissions commensurate with the Climate Change Act commitments and timescales and has identified the following short-term priorities

- Low-carbon heat strategy and plans to phase out fossil fuels in the 2020s from buildings not connected to the gas grid

- Policies to improve energy efficiency for all buildings

- New build standards to ensure all new homes are ultra-efficient and use low-carbon heating from 2025

- Closure of the performance and compliance gaps.

In the absence stronger policies and regulation by Government, several organisations have published their own strategies and recommendations of how the built environment could achieve the necessary operational carbon reductions to help meet the UK Climate Change Act[4] commitments. These include:

- LETI Climate emergency design guide[3]

- RIBA 2030 Climate challenge[5]

- UKGBC Net Zero Carbon Buildings framework[16]

[top]Operational carbon assessment

The operational carbon emissions of UK buildings are assessed using thermal modelling software. Various commercial dynamic thermal simulation models are available but the most common tools, which are used for demonstrating compliance with Part L, are SAP (Standard Assessment Procedure) for dwellings and SBEM (Simplified Building Energy Model) for non-domestic buildings.

SBEM is based on the National Calculation Method (NCM) which is a requirement under the EPBD (Energy Performance of Buildings Directive). The NCM sets out the methodology for calculating the annual operational energy use (and associated carbon emissions) for a proposed building and comparing it with the energy use of a comparable 'notional' building. Both calculations make use of standard sets of data for different activity areas and call on common databases of construction and service elements. A similar process is used to produce an 'asset rating' (which is required for an EPC) in accordance with the EPBD. The NCM therefore comprises the underlying method plus the standard data sets.

For compliance with Part L, the modelled Building CO2 Emissions Rate (BER) must be less that the Target Emission Rate (TER) which is based on a 2013 ‘notional, building (unchanged in 2016). The BER and TER are calculated using a monthly quasi-steady state energy balance methodology (SBEM).

[top]Embodied versus operational carbon

Although the relative significance of the embodied carbon impact of buildings is increasing as the operational energy efficiency of buildings is improved and the grid is decarbonised, designers can still make a far greater impact by addressing operational carbon reductions.

As mentioned and illustrated earlier in this article, the LETI guide[3] for new non-domestic buildings shows, operational carbon emissions still make up most (around 2/3) of the whole life carbon emissions of a building over 60 years and therefore remains the priority for reduction. Part of the reason why operational carbon still makes up such a large proportion of the whole life carbon impact is the performance gap between the anticipated and actual in-use energy consumption. Guides such as CIBSE TM54[17] provide a more robust estimate of actual performance of buildings than the predictions made for Part L compliance.

Although grid decarbonation should continue to reduce operational carbon emissions, it is clear that operational carbon reductions remain the priority with many cost-effective construction and renewable energy technologies readily available.

[top]Breakdown of energy use in buildings

To design more energy efficient buildings, it is important to understand the breakdown of energy use in buildings.

The pie-chart shows the breakdown of carbon emissions by energy demand in a Part L (2006 compliant) typical, large city centre office building and reveals that unregulated demands including appliances, IT, etc. make the biggest contribution to the total. Of the regulated energy demands, lighting and fans and pumps are the greatest contributors. This breakdown can help to identify where the biggest savings can be made most cost effectively. For example for this office building, analysis showed that the energy efficiency with the greatest predicted impact are those related to space cooling and fan and lighting efficiencies.

[top]Energy efficiency measures

Energy efficiency measures include improved thermal insulation levels and airtightness, improved lighting, improved glazing and solar control measures and improved HVAC efficiencies, etc. They can often represent the most cost effective means to reducing operational carbon emissions.

However, as operational carbon reduction targets become more onerous, the whole life cost effectives of many energy efficiency measures becomes less attractive than other measures, such as low and zero carbon technologies and allowable solutions.

The Target Zero design guides give guidance on the cost effectiveness of different energy efficiency measures for a range of new building types.

[top]LZC technologies

Low and zero carbon (LZC) technologies are broadly defined as technologies which meet building energy demands with either no carbon emissions, or with carbon emissions significantly lower than those of conventional methods. Generic LZC technologies include wind turbines, solar (hot water and pv), ground and air source heat pumps, combined heat and power (CHP) and combined cooling, heat and power (CCHP).

The cost effectiveness of introducing LZC technologies into buildings is highly dependent upon the cost of the technology and any relevant subsidies, such as the Feed-in tariffs and the Renewal Heat Incentive; both of which are subject to change.

It is important that the effectiveness of LZC technologies, in terms of both cost and carbon reduction, is assessed in conjunction with appropriate energy efficiency measures so that an optimum, compatible package of measures is defined. The Target Zero design guides give guidance on the cost effectiveness of different LZC technologies for new buildings.

[top]Optimum solutions for low and zero carbon design

The Target Zero programme assessed the operational carbon reductions achievable using individual energy efficiency measures and LZC technologies and ranked these in terms of their whole-life cost effectiveness. Target Zero also identified the most cost effective packages of compatible energy efficiency and LZC measures which could achieve what were, at the time the work was done, likely future Part L Carbon Compliance targets.

The Target Zero design guides provide summaries of the most cost effective packages of energy efficiency and LZC technology packages to achieve what were regarded as possible future likely operational carbon reduction targets. By way of example, the results for a typical secondary school are shown.

[top]Thermal mass

Main article: Thermal mass

Thermal mass, more appropriately called Fabric Energy Storage, is the ability of the fabric of a building to absorb heat. Effectively utilised, it can reduce cooling loads and, in some cases, remove the requirement to provide air conditioning entirely in some buildings. There is a common misconception that buildings must be heavyweight to achieve an optimum level of thermal mass. This myth has probably arisen because large buildings such as churches are always cool, even in the hottest summer. However, the main reasons that churches stay cool is because they have very few windows, which reduces solar gain, and have low internal heat gains.

In modern buildings, the greatest accessible mass is found in the upper floor slabs. Independent research has shown that in a UK climate, the optimum thickness of concrete floor slab for providing thermal mass is 75 - 100mm. This thickness of concrete floor slab is routinely available in almost all steel-framed buildings, which are also generally the lightest form of construction.

The extra weight associated with heavy, concrete frames is not required to improve thermal mass and is surplus to requirements. In fact, the extra mass of heavyweight concrete components may actually increase the energy required to heat and cool the building.

To be effective, it is important that thermal mass solutions are integrated with building servicing strategy, particularly the ventilation strategy.

Systems for mobilising thermal mass are generally described as either passive or active. All of these systems can be utilised effectively in steel-framed buildings. Passive systems rely on natural ventilation to disperse the heat absorbed by the upper floor slabs whereas in active systems, the heat exchange with the structure is enhanced by mechanical ventilation, either within the core of the slab or over its surface. Active systems are generally air-based or liquid-based systems

The Wessex Water HQ in Bath in which coffered concrete floor units on a steel frame have been used to provide an efficient naturally ventilated, low energy building is shown.

[top]BREEAM

Main articles: BREEAM, Target Zero

BREEAM (Building Research Establishment’s Environmental Assessment Method) is the world’s leading and most widely used environmental assessment method for buildings. In the UK it has become the de facto measure or standard for the environmental performance of non-domestic buildings. BREEAM is updated on a regular basis to keep pace with best practice and related regulations, notably the Part L requirements for operational energy efficiency. The current version is BREEAM Uk new construction 2018[18]. Different BREEAM schemes are also available for communities, infrastructure, in-use and refurbishment and fit-out.

[top]Understanding BREEAM

- Steel-framed, BREEAM 'excellent' buildings

BREEAM is a performance-based assessment method and certification scheme for new buildings. Buildings assessed under BREEAM are awarded credits according to their performance within a range of nine environmental categories: management, energy use, health and well-being, pollution, transport, land use, ecology, materials and water. Credits are either mandatory, i.e. must be achieved for compliance, or voluntary. In addition, there are innovation credits which encourage exemplar performance or which recognise a building that innovates in the field of sustainable performance.

Credits achieved are weighted according to environmental category and then summed to produce a single overall score on a scale of Unclassified, Pass, Good, Very Good, Excellent and Outstanding.

Building projects are assessed by registered assessors and reviewed by a third party (BRE Global) before being awarded a certificate. Since 2008 it has been compulsory to undertake a ‘Post Construction Review’ to confirm that the ‘as built’ information correlates with the design information. The BREEAM rating benchmark levels enable a client or other stakeholder to compare an individual building’s performance with other BREEAM rated buildings and the typical sustainability performance of new non-domestic buildings in the UK. In this respect each BREEAM rating level broadly represents performance equivalent to:

- Outstanding: Less than top 1% of UK new non-domestic buildings (innovator)

- Excellent: Top 10% of UK new non-domestic buildings (best practice)

- Very Good: Top 25% of UK new non-domestic buildings (advanced good practice)

- Good: Top 50% of UK new non-domestic buildings (intermediate good practice)

- Pass: Top 75% of UK new non-domestic buildings (standard good practice).

Although voluntary, a number of Government departments and other public bodies either require or encourage the use of BREEAM. These include the Welsh Assembly Government, the Northern Ireland Executive, UK health authorities and the Department for Education. Many private sector clients and developers also use BREEAM to deliver sustainable buildings.

[top]Material assessment within BREEAM

Under BREEAM, construction materials are assessed under five issues Mat 01, Mat 02, Mat 03, Mat 05 and Mat 06 with a maximum of 14 credits available.

The life cycle environmental impacts of construction materials and products are assessed under Mat 01 using either the BREEAM simplified LCA tool, IMPACT compliant tools or other building LCA tools recognized by BREEAM. Building element ratings are aggregated to give a whole building score for which a maximum of seven Mat 01 credits are available.

Reflecting the growing importance associated with material impacts, the Materials weighting in BREEAM 2018[18] has increased to 15% (fully fitted out) and 22% (shell only).

[top]Sustainable procurement and responsible sourcing

There is growing demand within the construction industry to demonstrate that buildings are sustainably procured and that their constituent materials and components are responsibly sourced.

[top]Sustainable procurement

Sustainable procurement is procurement that aims to deliver real long term value. It involves understanding and assessing the effect of goods and services on the environment, the communities affected by its supply chain and the economy and then taking steps to reduce any negative effects and promote benefits wherever feasible.

It is about using purchasing power to benefit the environment, society and the economy. This means including sustainable considerations alongside the traditional criteria of purchase price, quality and service and making purchasing decisions that achieve best value for money over the lifetime of the goods.

Introduced by the Government’s Sustainable Task Force in 2006, the Flexible Framework is a key sustainable procurement tool. It lists the steps needed at an organisational level to improve procurement practice and covers five themes:

- People

- Policy, strategy and communication

- Procurement process

- Engaging suppliers

- Measurement and results.

More detailed information and advice on sustainable procurement is provided in BS ISO 20400[19].

[top]Sustainable procurement within the steel sector

Raw materials for steelmaking are responsibly sourced by companies such as British Steel and Tata Steel, who champion environmentally responsible practices throughout their supply chains. This provides a route for their customers to obtain responsible sourcing credits under the BREEAM family of certification schemes.

The leading UK manufacturers and suppliers of structural steel, British Steel and Tata Steel, have all been certified under the BRE Environmental & Sustainability Standard BES 6001[20], a responsible sourcing certification for the UK construction market.

For these companies, sustainable procurement is part of a wider corporate responsibility that involves the integration of financial and strategic goals with a commitment to the health, safety and well-being of their employees and communities; a focus on improving environmental performance and providing sustainable products, and conducting all aspects of their business with honesty and integrity.

[top]Responsible sourcing standards

Responsible sourcing of construction products is included within the Government’s 2008 Sustainable Construction Strategy[21] which includes the target to develop Framework Standards to facilitate the development of sector Responsible Sourcing schemes. Since 2008, two standards have been produced BES 6001[20] and BS EN 8902[22].

Responsible Sourcing is also included within BREEAM 2018. All materials used to construct a building are assessed for the level of certification achieved. Recognised schemes include BES 6001[20], environmental management systems (EMS) such as ISO 14001 and FSC (Forest Stewardship Council), etc.

[top]The UK steel construction sector

The UK steel construction sector is leading the way in developing a more sustainable construction industry for the UK. Our commitments range from producing design guidance on creating buildings that meet the Government’s low and zero carbon targets to researching the environmental impact of steel in buildings and developing products and processes to reduce that impact.

[top]Sector commitments

Reducing the carbon footprint of buildings is set to remain a top priority for the UK steel construction sector. The UK steel construction sector is committed to:

- Working with Government to meet the objectives of its sustainable construction strategy[21].