Difference between revisions of "Twin Sails Bridge, Poole"

| Line 51: | Line 51: | ||

The client and the public are delighted with this iconic and vital [[Bridges|bridge]]. | The client and the public are delighted with this iconic and vital [[Bridges|bridge]]. | ||

| − | [[Category:Case studies | + | [[Category:Case studies - Bridges]] |

[[Category:SSDA]] | [[Category:SSDA]] | ||

Latest revision as of 12:19, 12 March 2019

Structural Steel Design Awards 2013 - Award

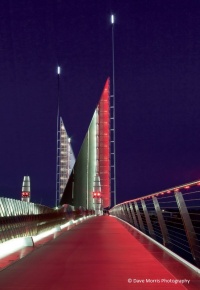

The Twin Sails Bridge is at the heart of Poole’s plans for the future and will unlock one of the largest regeneration sites in south west England. The five span lifting bridge crosses Poole’s Backwater Channel and is a dramatic new landmark.

Traffic regularly ground to a standstill when the existing bridge opened for maritime traffic. With the new bridge operating in sequence with the existing bridge, there will now always be a route for vehicles over the Backwater Channel, significantly reducing disruption.

The bridge, with its soaring landmark carbon fibre masts and high standard of finishing and sophisticated lighting, ensures that each operation of the bridge is a spectacle. When closed the low level span mirrors the flat surrounding landscape of Poole town but, when open, visually echoes yachts and sailboats – an acknowledgement of the area’s maritime heritage.

The deck in the pivot zone contains observation windows allowing pedestrians and vehicle occupants to see across the Channel to the opposing sail and enjoy dramatic views of the structure’s operation.

The bridge was designed to nationally accepted standards as defined by the Highways Agency (HA). Due diligence was paid to the Construction Regulations and included assessments of risk to the health and safety of those constructing, maintaining, using and demolishing the structure.

An Environmental Impact Assessment was undertaken during the project leading to the development of a waste management and recycling strategy during construction. All design decisions relating to structural form and materials were assessed in relation to their environmental impact during construction and throughout the bridge’s life.

Materials were selected to maximise durability and minimise maintenance requirements throughout the life of the structure. The lift span deck utilises weathering steel to remove the need for maintenance painting of the internal surfaces within the box. The footways decking is lightweight aluminium and the parapets comprise corrosion resistant stainless steel. The main deck of the approaches is a steel composite construction with concrete deck.

The structure is a double leaf bascule bridge in method, but untraditional in that there are no counterweights. The operation is managed by two hydraulic rams for each sail at normal operational speed – each ram providing sufficient strength to enable the bridge to continue to operate during maintenance possession, but with a reduced operational speed. The rams and hydraulic pumps servicing them are housed in plant rooms within the main supports either side of the navigation channel.

The adaptability of steelwork and its ability to create robust yet lightweight sculpted forms made it the ideal material for fabricating the triangular ‘sails’ of the lifting span. In addition, the use of steelwork acting compositely with a concrete deck for the approach spans also was an ideal solution to produce the desired shallow deck profile. Overall, this enabled the creation of an elegant yet unassuming bridge in the closed position, in keeping with the surrounding landscape, yet creating a dramatic and iconic vision each time the bridge opens for marine traffic.

Tapering transverse steel beams cantilever from the longest catheti edge to support the lightweight perforated deck and steel parapets, drawing the eye away from the deck itself and serving to reduce wind loading when in the open position.

The bridge is an exemplar of innovation. The diagonal cut of the central lifting span creating the impression of two passing sails is unique. The diagonal joint enables the leading point of each triangular leaf to land on a permanent bearing on the main support. This significantly reduces differential deflection as vehicles pass over the joint and removes reliance on hydraulic nose pin interlocks between adjacent leaves.

The diagonal joint format and bearing approach has enabled a passive wedge interlock arrangement between leaves along the joint to be developed; one which requires little maintenance.

The use of weathering steel for the lift span boxes removes the requirement for painting of the internal surfaces; a significant benefit for health and safety and the long term maintenance strategy. External steel surfaces were coated with a modern protective paint system compliant with the latest HA standards ensuring extended life to major maintenance in excess of 25 years. The curved form of the superstructure will also serve to extend the life of the paint system.

The bridge features two distinct structural forms; the approach spans constructed as composite steel boxes with curved soffits, and the triangular lifting spans comprising fabricated steel boxes with orthotropic deck plates, again with curved soffits. The abutments and piers sit on top of 53 foundation piles, mostly 1.2m in diameter and sunk 31m into the Channel bed. The deck and sails were made up of 41 sections of steel.

The construction process itself was inventive. The most economical method of constructing this bridge was to fabricate much of the steel superstructure offsite. Modular sections were brought to the site, assembled to form individual deck spans and welded together on the quayside adjacent to the Channel.

Once assembled each span of the superstructure was jacked up off temporary supports on self-propelled modular transporters (SPMTs), driven onto a barge and floated into position. Making use of the falling tide and fine adjustment from the SPMTs, each deck element was lowered onto permanent bearings allowing the barge with transporters to be removed. This was repeated for each of the approach spans and each lifting leaf, negating the need for significant craneage and reducing the amount of temporary works and assembly work over the water.

| Architect | Wilkinson Eyre Architects |

| Structural Engineer | Ramboll |

| Steelwork Contractor | Cleveland Bridge UK Ltd |

| Main Contractor | Hochtief (UK) Construction Ltd |

| Client | Borough of Poole |

Judges' comment

This ingenious design for an opening traffic bridge combines elegance and functional efficiency. When closed, the slender deck blends with the surrounding landscape, and when open the tapering arms create a dramatic landmark, reflecting the masts and sails of passing boats. The detailing and fabrication are of the highest standard, and ensure easy maintenance.

The client and the public are delighted with this iconic and vital bridge.