Influence of design on corrosion

The design of a structure can affect the durability of any protective coating applied to it. Structures designed with many small structural components and fasteners are more difficult to protect than those with large flat surfaces.

Detailing is important to ensure that the protective treatment can be applied to all surfaces, to avoid the creation of water and dirt traps that would accelerate corrosion, and could lead to pitting corrosion. Detailing is also important to ensure that future inspection and maintenance can be carried out effectively. Guidance for the prevention of corrosion by good design detailing can be found in BS EN ISO 12944-3[1]

[top]Access for coating application and maintenance

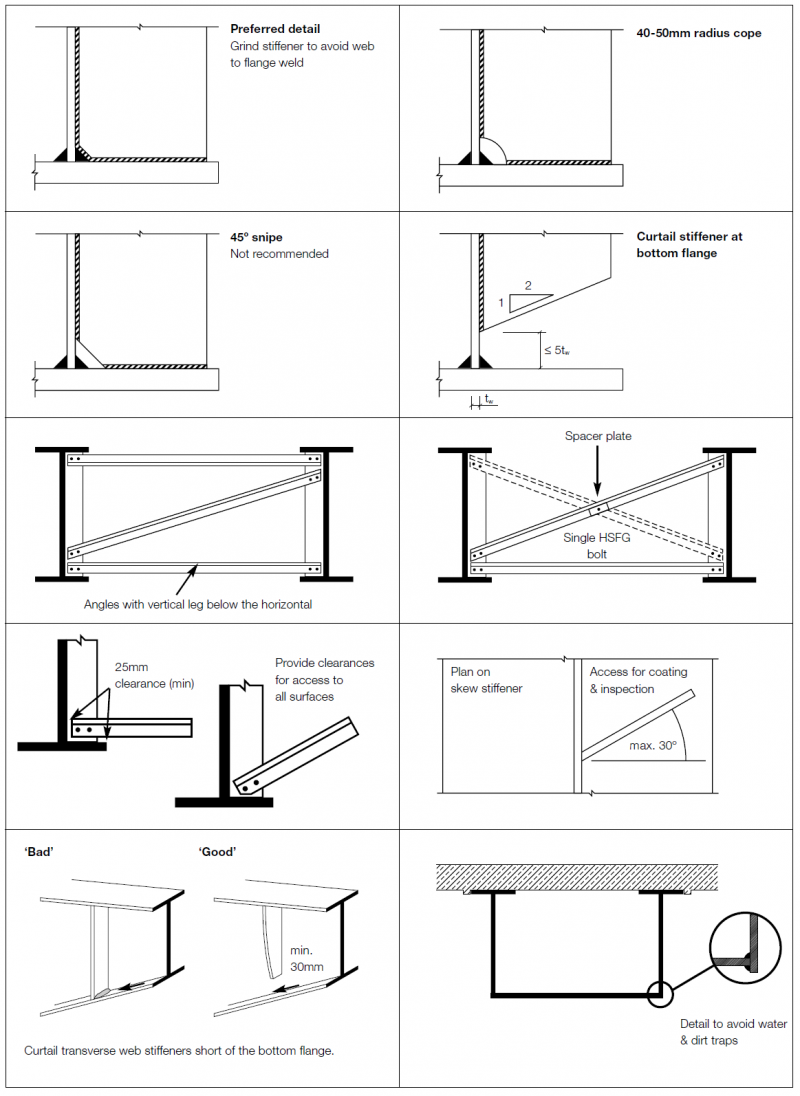

Access to all surfaces to provide both the initial surface treatment and subsequent maintenance painting is essential. Narrow gaps, difficult to reach corners, and hidden surfaces should be avoided wherever possible. Similarly, clearance between connecting members at junctions, and the degree of internal angles at skewed web stiffeners should allow access for coating and inspection.

A typical detail that is difficult to protect is a cope hole in a web stiffener. Unless the hole is very large, it is virtually impossible to blast clean the surface properly and to apply a protective treatment to the surface. Ideally copes should be avoided by using close fitting snipes and a continuous weld around the corner. Although this may form a moisture/dirt trap, it is considered a better detail than having a drainage path through a cope where the protection system is at its most vulnerable. If cope holes are used, they should be circular and of at least 50mm radius, preferably more. Cope holes formed by 45º snipes should not be used. The weld will not be returned through the hole, which creates the additional problem of a narrow crevice.

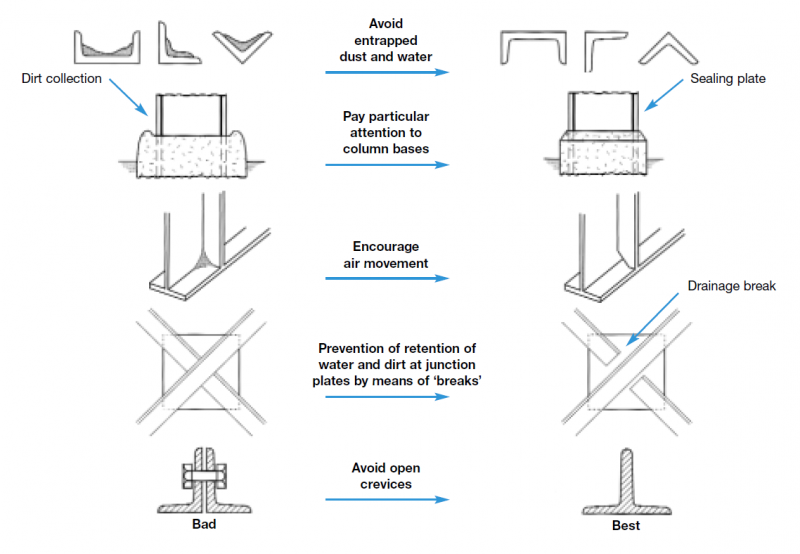

[top]Avoidance of moisture and debris traps

Details that could potentially trap moisture and debris should be avoided where possible. Measures that can be taken include:

- Grind flush weld on horizontal surfaces.

- Curtail transverse web stiffeners short of the bottom flange.

- Avoid using channels with toes upward.

- Arrange angles with the vertical leg below the horizontal.

- Avoid the use of ‘T’ section bearing stiffeners.

- Avoid the creation of cavities and crevices etc.

- Seal rolled hollow sections except when they are to be hot-dip galvanized.

Examples of detailing to minimise corrosion in buildings and bridges are shown below.

[top]Crevices

Crevices attract and retain water through capillary action, leading to accelerated 'crevice corrosion', so details such as lap joints should be avoided or sealed where possible.

Preloaded bolted joints pose a particular problem on bridges, so welded connections are preferable in terms of corrosion protection. However, crevice effects on preloaded bolted connections can be minimised by limiting the bolt spacing and edge distance, using flexible cover plates, and sealing the edges of the joint. Crevices at the intersections of cross bracings should be avoided by using a packing plate the same thickness as the web stiffener, and a single preloaded bolt through all three pieces.

[top]Drainage and ventilation

Provision should be made for adequate drainage and ventilation to enable the steel to dry out, e.g. minimise the ‘time of wetness’. Measures to be considered include the provision of drainage holes where necessary, and the provision of free circulation of air around the structure.

For bridges, closely spaced girders should be avoided and deck run-off should be directed away from steel surfaces. In addition, the use of wide cantilevers with suitable drip details should be considered.

The articulation of a bridge also influences its durability as leaking deck joints have often been the source of corrosion problems. Ideally, expansion joints should be avoided by the use of continuous and integral construction. However, if expansion joints are unavoidable they should be located away from the ends of the girders and a positive non-metallic drainage system should be provided to convey any leaks away from the steelwork.

[top]Contact with other materials

Inevitably, structural steelwork will come into contact with other materials, and designers should carefully consider the implication on corrosion performance:

- Connections between dissimilar metals should be avoided where practical otherwise there is a risk of accelerated bimetallic corrosion. If this cannot be avoided, then the contact surfaces should be insulated.

- Adequate depth of cover, and the correct quality of concrete should be specified where structural steelwork is to be encased in concrete.

- Structural steel should be separated from timber by the use of coatings or sheet plastics to avoid dampness on the steel surface.

[top]References

- ↑ BS EN ISO 12944-3: 1998, Paints and varnishes – Corrosion protection of steel structures by protective paint systems – Part 3: Design considerations, British Standards Institution

[top]Resources

- Steel Buildings, 2003, The British Constructional Steelwork Association Ltd.

- Chapter 12 – Corrosion Protection

[top]Further Reading

- D.Deacon & R.Hudson (2012), Steel Designer’s Manual (7th Edition), Chapter 36 - Corrosion and corrosion prevention, The Steel Construction Institute.

- D.A. Bayliss & D.H.Deacon (2002), Steelwork Corrosion Control (2nd edition), Spon Press.

[top]See also

- Corrosion of structural steel

- Surface preparation

- Paint coatings

- Standard corrosion protection systems for buildings

- Metallic coatings

- Appropriate specifications

- Inspection and quality control