Standard corrosion protection systems for buildings

This article is designed to assist those responsible for either drafting corrosion protection specifications, or as contractors with a requirement to meet that which is specified. The information provided is based upon industrial experience, and is in the form of current practice tables of ‘standard’ corrosion protection systems for steelwork in a range of environments.

[top]Introduction

The tables of ‘standard’ systems for steelwork presented in this article relate to ‘environment categories’ which are based upon those given BS EN ISO 12944-2[1] and BS EN ISO 9223[2], which are described in the table below.

| Corrosivity category | Low-carbon steel Thickness loss (μm)a | Examples of typical environments (informative only) | |

|---|---|---|---|

| Exterior | Interior | ||

| C1 very low |

≤ 1.3 | - | Heated buildings with clean atmospheres, e.g. offices, shops, schools, hotels |

| C2 low |

> 1.3 to 25 | Atmospheres with low level of pollution: mostly rural areas | Unheated buildings where condensation can occur, e.g. depots, sports halls |

| C3 medium |

> 25 to 50 | Urban and industrial atmospheres, moderate sulphur dioxide pollution; coastal area with low salinity | Production rooms with high humidity and some air pollution, e.g. food-processing plants, laundries, breweries, dairies |

| C4 high |

> 50 to 80 | Industrial areas and coastal areas with moderate salinity | Chemical plants, swimming pools, coastal ship and boatyards |

| C5 very high |

> 80 to 200 | Industrial areas with high humidity and aggressive atmosphere and coastal areas with high salinity | Buildings or areas with almost permanent condensation and high pollution |

| CX extreme |

> 200 to 700 | Offshore areas with high salinity and industrial areas with extreme humidity and aggressive atmosphere and sub-tropical and tropical atmospheres | Industrial areas with extreme humidity and aggressive atmosphere |

Notes:

- 1μm (1 micron) = 0.001mm

- a The thickness loss values are after the first year of exposure. Losses may reduce over subsequent years.

- The loss values used for the corrosivity categories are identical to those given in BS EN ISO 9223[2].

In many instances, steelwork will be in a warm dry interior where it will not corrode, and the structural stability of the building will not be threatened during its design life (generally taken as 50 years). In such conditions (classified as C1) no corrosion coating is required. Examples include steelwork inside dry buildings with neutral atmospheres such as multi-storey office buildings, shops, schools, hotels, residential buildings, airport terminals, and hospitals, etc.

However, when steelwork is exposed to moisture, corrosion will occur at a rate depending on the severity of the environment. In such cases, a coating system appropriate to the environment category should be provided. Note that some buildings may contain areas where different environment conditions apply e.g. hospitals would normally be C1, but may contain kitchens and laundry areas that would normally be C3. Some types of buildings, such as car parks may fall into any of the above categories or combinations of them depending upon their location, design and construction. Higher risk categories for interior environments (e.g. C4 and C5) are not covered in this article and users are advised to seek specialist advice if their project involves such situations.

The protective systems in the tables have unique identities. The film thicknesses given in the tables are nominal dry film values (μm = micron = 0.001mm). The tables also identify the nearest equivalent system in BS EN ISO 12944-5[3] , and the required surface preparation to BS EN ISO 8501-1[4]

[top]Interior environments

In deriving the protection systems described on these pages, the design life of building structures has been taken as 50 years. The tables give two figures for durability:

Structure life

The period of reasonable freedom from severe corrosion of the steelwork that might lead to weakening of the structure. This figure assumes no mechanical damage in service that no maintenance is carried out and that up to 1mm of steel may be lost from the surface at the corrosion rate for each environment given in BS EN ISO 12944-2[1]. Visible steelwork will normally be accessible for maintenance and if repainting is carried out the quoted structure life will be extended.

Coating life

The expected period to maintenance of the protective coating. More frequent re-coating may often be preferred for decorative reasons because of fading, contamination, wear and tear, etc. Hidden steelwork is assumed to be not accessible for maintenance, thus a figure for coating life of hidden steelwork systems is not applicable.

[top]Hidden steelwork

| System number | IH-C2-A | IH-C2-B | IH-C2-C |

|---|---|---|---|

| Structure life | 50+ | 50+ | 50+ |

| Coating life | n/a | n/a | n/a |

| Nearest equivalent BS EN ISO 12944-5[3] | - | C2.07 | C2.01 or C2.05 |

| Surface preparation to BS EN ISO 8501-1[4] | Manual clean to St2 | Blast clean to Sa 2½ | Blast clean to Sa 2½ |

| Factory applied coatings | - | Zinc phosphate epoxy primer (note 1) 80μm |

Water based acrylic or Water based epoxy zinc phosphate primer 2 coats 2x60μm=120μm total |

| Site applied coatings | High build Bitumen 150μm |

- | - |

| System number | IH-C3-A | IH-C3-B | IH-C3-C |

|---|---|---|---|

| Structure life | 50+ | 50+ | 50+ |

| Coating life | n/a | n/a | n/a |

| Nearest equivalent BS EN ISO 12944-5[3] | C3.07 | - | C3.10 |

| Surface preparation to BS EN ISO 8501-1[4] | Blast clean to Sa 2½ | - | Blast clean to Sa 2½ |

| Factory applied coatings | Hydrogen modified epoxy 300μm |

Hot-dip galvanize to BS EN ISO 1461[5] (note 2) |

i) High build zinc phosphate epoxy primer 80μm (note 1) ii) High build recoatable epoxy MIO 120μm (note 3) |

| Site applied coatings | - | - | - |

Notes to tables:

- The thickness values given for primers are the total thickness used and may include a prefabrication primer. For example, 80µm can be in one coat or as 20µm prefabrication primer plus 60µm post-fabrication primer.

- For steel profiles over 6mm thick the minimum average thickness of galvanized coatings to BS EN ISO 1461[5] is 85µm

- MIO - micaceous iron oxide.

[top]Visible steelwork

| System number | IV-C2-A | IV-C2-B | IV-C2-C |

|---|---|---|---|

| Structure life | 50+ | 50+ | 50+ |

| Coating life | 10 | 15 | 12 |

| Nearest equivalent BS EN ISO 12944-5[3] | C2.04 | C2.03 | C2.01 or C2.05 |

| Surface preparation to BS EN ISO 8501-1[4] | Manual clean to St2 | Blast clean to Sa 2½ | Blast clean to Sa 2½ |

| Factory applied coatings | - | High build zinc phosphate epoxy primer 80μm (note 1) |

Water based acrylic or Water based epoxy zinc phosphate primer 60μm |

| Site applied coatings | i) Zinc phosphate alkyd primer 40μm (note 2) ii) High build zinc phosphate alkyd primer 80μm iii) Alkyd finish 60μm |

Alkyd finish 60μm | Water based acrylic or Water based epoxy finish 60μm |

| System number | IV-C3-A | IV-C3-B | IV-C3-C |

|---|---|---|---|

| Structure life | 50+ | 45 | 40 |

| Coating life | 40+ | 25 | 20 |

| Nearest equivalent BS EN ISO 12944-5[3] | - | C3.07 | C3.06 |

| Surface preparation to BS EN ISO 8501-1[4] | - | Blast clean to Sa 2½ | Blast clean to Sa 2½ |

| Factory applied coatings | Hot-dip galvanize to BS EN ISO 1461[5] (note 3) |

i) Zinc phosphate epoxy primer 80μm (note 1) ii) High build epoxy MIO 100μm |

i) High build zinc phosphate epoxy primer 120μm (note 1) ii) High solid aliphatic polyurethane finish 60μm |

| Site applied coatings | (note 4) | Recoatable polyurethane finish 60μm | - |

Notes to tables:

- The thickness values given for primers are the total thickness used and may include a prefabrication primer. For example, 80µm can be in one coat or as 20µm prefabrication primer plus 60µm post fabrication primer.

- A ‘wetting’ low viscosity primer is recommended to obtain satisfactory performance.

- For steel profiles over 6mm thick the minimum average thickness of galvanized coatings to BS EN ISO 1461[5] is 85µm.

- To enhance durability and improve the aesthetic appearance, the hot-dip galvanized coating can be treated with a mordant wash or ‘T’ wash followed by a vinyl primer at 40µm and a vinyl finish at 60µm.

- MIO - micaceous iron oxide.

[top]Swimming pools

| System number | SP-C4-A | SP-C4-B | SP-C4-C |

|---|---|---|---|

| Structure life | 50+ | 50+ | 50+ |

| Coating life | 10+ (note 1) | 25 | 25 |

| Nearest equivalent BS EN ISO 12944-5[3] | G4.02 | C4.07 | C4.11 |

| Surface preparation to BS EN ISO 8501-1[4] | - | Blast clean to Sa 2½ | Blast clean to Sa 2½ |

| Factory applied coatings | i) Hot-dip galvanize to BS EN ISO 1461[5] (note 2) ii) Mordant wash or etch primer or sweep blast (note 3) iii) Surface tolerant epoxy 75μm |

i) Zinc phosphate epoxy primer 80μm ii) Pigmented epoxy 2 coats, 200μm total |

i) Zinc phosphate epoxy primer 80μm ii) Epoxy MIO 2 coats, 200μm total |

| Site applied coatings | Acrylic urethane 50μm | Aliphatic polyurethane finish 60μm | Recoatable polyurethane finish 60μm |

Notes to table:

- The Coating Life is estimated for the paint system only and does not include the hot-dip galvanized coating. The life of the total protection system without maintenance should exceed 25 years, however, it is anticipated that for aesthetic reasons maintenance will be carried out at periods of 10 years or less.

- For steel profiles over 6mm thick the minimum average thickness of galvanized coatings to BS EN ISO 1461[5] is 85µm. For hidden steelwork, e.g. behind a suspended ceiling, no further treatment is required. For steelwork that is visible, the galvanized coating should be surface treated and coated as shown.

- Methods of preparing hot-dip galvanized coatings need to ensure that a satisfactory condition is achieved to accept a paint coating system. It is important that the steelwork is thoroughly degreased and free from any contamination. Several methods can be considered including:

- Mordant wash or 'T' wash, which is the brush application of a chemical solution that reacts with the galvanized surface. The effectiveness of the solution is readily visible and untreated areas are self evident. After treatment, the solution should be rinsed off with clean water and then the treated surface dried ready for painting. It is important that the manufacturers' instructions are carefully followed to ensure successful results.

- Etch primers, which can be either single or two pack materials and they are applied as thin film coatings to around 10μm to 25μm in thickness. The two pack versions tend to provide an improved surface compared with the single pack

- Sweep blasting, which is the use of low pressure fine grade non-metallic abrasive which can be very effective but requires care and expertise. The treatment should slightly roughen the galvanized surface without removing the coating.

- MIO - micaceous iron oxide.

[top]Exterior environments

Coating system durability given in the following tables is based on practical experience. It is the expected life, in years, before first major maintenance. This is taken as degradation level Ri3 from BS EN ISO 4628-3[6] (1% of surface area rusted). It should be noted that this does not imply a guarantee of life expectancy. The durability of galvanized steelwork is derived from the figures in BS EN ISO 14713[7].

| System number | E-C3-A | E-C3-B | E-C3-C |

|---|---|---|---|

| Coating life | 20+ | 20 | 20 |

| Nearest equivalent BS EN ISO 12944-5[3] | - | C3.07 | C3.09 |

| Surface preparation to BS EN ISO 8501-1[4] | - | Blast clean to Sa 2½ | Blast clean to Sa 2½ |

| Factory applied coatings | Hot-dip galvanize to BS EN ISO 1461[5] (notes 1 & 2) |

i) Zinc phosphate epoxy primer 80μm (note 3) ii) High build epoxy MIO 100μm |

i) High build zinc phosphate epoxy primer 100μm (note 3) ii) High solid aliphatic polyurethane finish 60μm |

| Site applied coatings | - | Recoatable polyurethane finish 60μm | - |

| System number | E-C4-A | E-C4-B | E-C4-C |

|---|---|---|---|

| Coating life | 15-20 | 20 | 20+ |

| Nearest equivalent BS EN ISO 12944-5[3] | C4.11 | - | - |

| Surface preparation to BS EN ISO 8501-1[4] | Blast clean to Sa 2½ | Blast clean to Sa 2½ | Blast clean to Sa 2½ |

| Factory applied coatings | i) Zinc rich epoxy primer 40μm (note 6) ii) High build epoxy MIO 100μm |

i) Zinc phosphate epoxy primer 80μm ii) High build glass flake epoxy 300μm |

i) Zinc phosphate epoxy primer 25μm (note 7) ii) Elastomeric urethane 1000μm (note 8) |

| Site applied coatings | High build epoxy MIO 100μm (notes 4 & 5) | Recoatable polyurethane finish 60μm | Recoatable polyurethane finish 60μm |

| System number | E-C5-A | E-C5-B | E-C5-C |

|---|---|---|---|

| Coating life | 15 | 20 | 15 |

| Nearest equivalent BS EN ISO 12944-5[3] | TSM5.01 | C5.08 | G5.04 |

| Surface preparation to BS EN ISO 8501-1[4] | Blast clean to Sa 3 | Blast clean to Sa 2½ | - |

| Factory applied coatings | i) Sprayed aluminium to BS EN ISO 2063[8][9] 150μm (note 9) ii) Zinc phosphate epoxy sealer coat 50μm iii) High build epoxy MIO 100μm (note 4) |

i) Zinc rich epoxy primer 40μm (note 6) ii) High build epoxy MIO 200μm total (one or two coats) (note 4) |

i) Hot-dip galvanize to BS EN ISO 1461[5] (note 1) ii) Mordant wash iii) Etch primer 40μm iv) High build epoxy MIO 100μm (note 4) |

| Site applied coatings | Recoatable polyurethane finish 60μm | High solid aliphatic polyurethane finish 60μm | Recoatable polyurethane finish 60μm |

Notes to tables:

- For steel profiles over 6mm thick the minimum average thickness of galvanized coatings to BS EN ISO 1461[5] is 85µm.

- Where painting of galvanized steelwork is required for aesthetic or other reasons; suitable systems from BS EN ISO 12944-5[3] may be used.

- The thickness values given for primers are the total thickness used and may include a prefabrication primer. For example, 80µm can be in one coat or as 20µm prefabrication primer plus 60µm post fabrication primer.

- MIO - micaceous iron oxide.

- It should be noted that the colour range of MIO is limited.

- The zinc rich primer applied at 80µm would increase the durability of the system by approximately 5 years.

- The primer coat may be omitted providing the build/intermediate coat is applied directly to a clean steel substrate of suitable surface profile.

- With time, elastomeric urethanes may suffer from superficial degradation known as ‘chalking’ which changes the visual appearance but does not affect the over all durability of the system. Where colour stabilization is required for appearance purposes, this can be achieved by the application of the finish coat in this system.

- The protection of structural steelwork against atmospheric corrosion by thermal sprayed aluminium or zinc coatings is covered in BS EN ISO 2063-1[8] and BS EN ISO 2063-2[9].

[top]Perimeter walls

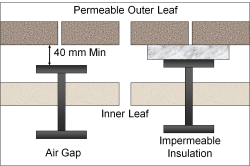

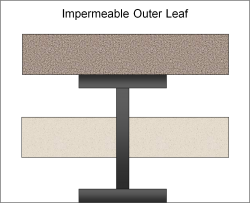

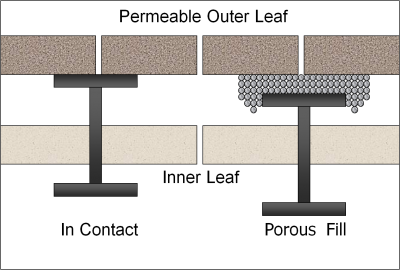

[top]Steelwork in clear separation from outer leaf

For wall cavities in which steel will remain dry, either by use of an impermeable outer leaf or where there is physical separation of the steel from the outer leaf, a system from the ‘Hidden steelwork’ section for environment categories C1, C2 or C3 may be appropriate. The treatment specified for cavity wall condition should also be suitable for the interior environment of the building. Should the internal environment be more aggressive, additional protection will be required.

| System number | PW-C2-S |

|---|---|

| Structure life | 50+ |

| Coating life | n/a |

| Nearest equivalent BS EN ISO 12944-5[3] | C3.08 |

| Surface preparation to BS EN ISO 8501-1[4] | Blast clean to Sa 2½ |

| Factory applied coatings | Zinc phosphate epoxy primer (note 1) 80μm |

| Site applied coatings | (note 2) |

Notes to table

- The thickness values given for primers are the total thickness used and may include a prefabrication primer. For example, 80µm can be in one coat or as 20µm prefabrication primer plus 60µm post-fabrication primer.

- The environment within a ‘normal’ cavity wall construction is categorised as being C2. The system PW-C2-S is considered appropriate for such conditions. However, where steelwork within the cavity is deemed to be in a more aggressive environment category, the application of a high build bitumen coating at 150µm to the faces of the steelwork within the cavity may be applied before or during construction.

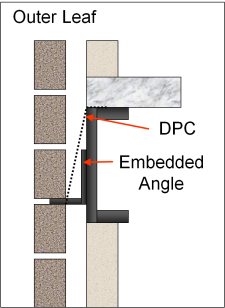

[top]Steelwork in contact with outer leaf

Brickwork cladding or other masonry, can develop cracks and leakage over time. When steelwork is in contact with, or embedded in a brick/masonry outer leaf, one of the following systems should be used. In some regions, stainless steel may be required for embedded members by local regulations or be deemed necessary to provide adequate durability. Specialist advice should be sought.

| System number | PW-C2-A | PW-C2-B |

|---|---|---|

| Structure life | 50+ | 50+ |

| Coating life | n/a | n/a |

| Nearest equivalent BS EN ISO 12944-5[3] | - | - |

| Surface preparation to BS EN ISO 8501-1[4] | Blast clean to Sa 2½ | - |

| Factory applied coatings | One coat solvent free epoxy 450μm | i) Hot-dip galvanize to BS EN ISO 1461[5] 85μm ii) Two coats heavy duty bitumen, 200μm total |

| Site applied coatings | - | - |

[top]References

- ↑ 1.0 1.1 1.2 BS EN ISO 12944-2: 2017, Paints and varnishes – Corrosion protection of steel structures by protective paint systems – Part 2: Classification of environments, BSI

- ↑ 2.0 2.1 BS EN ISO 9223: 2012, Corrosion of metals and alloys – Corrosivity of atmospheres – Classification, determination and estimation. BSI

- ↑ 3.00 3.01 3.02 3.03 3.04 3.05 3.06 3.07 3.08 3.09 3.10 3.11 BS EN ISO 12944-5: 2019, Paints and varnishes, Corrosion protection of steel structures by protective paint systems, Protective paint systems, BSI

- ↑ 4.00 4.01 4.02 4.03 4.04 4.05 4.06 4.07 4.08 4.09 4.10 BS EN ISO 8501-1: 2007, Preparation of steel substrates before application of paints and related products. Visual assessment of surface cleanliness. Rust grades and preparation grades of uncoated steel substrates and of substrates after overall removal of previous coatings, ISO

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 BS EN ISO 1461: 2009, Hot dip galvanized coatings on fabricated iron and steel articles. Specifications and test methods. BSI

- ↑ BS EN ISO 4628-3: 2016 Paints and varnishes - Evaluation of degradation of coatings - Designation of quantity and size of defects, and of intensity of uniform changes in appearance - Part 3: Assessment of degree of rusting. BSI

- ↑ BS EN ISO 14713-1: 2017 Zinc coatings. Guidelines and recommendations for the protection against corrosion of iron and steel in structures. General principles of design and corrosion resistance. BSI

- ↑ 8.0 8.1 BS EN ISO 2063-1: 2019, Thermal spraying, Zinc, aluminium and their alloys, Design considerations and quality requirements for corrosion protection systems, BSI

- ↑ 9.0 9.1 BS EN ISO 2063-2: 2017, Thermal spraying, Zinc, aluminium and their alloys, Execution of corrosion protection systems, BSI

[top]Resources

- Hendy, C.R.; Iles, D.C. (2015) Steel Bridge Group: Guidance Notes on best practice in steel bridge construction (6th Issue). (P185). SCI

- Steel Buildings, 2003, The British Constructional Steelwork Association Ltd.

- Chapter 12 – Corrosion Protection

[top]Further reading

- D.Deacon & R.Hudson (2012), Steel Designer’s Manual (7th Edition), Chapter 36 - Corrosion and corrosion prevention, The Steel Construction Institute.

- D.A. Bayliss & D.H.Deacon (2002), Steelwork Corrosion Control (2nd edition), Spon Press.

[top]See also

- Corrosion of structural steel

- Influence of design on corrosion

- Surface preparation

- Paint coatings

- Metallic coatings

- Appropriate specifications

- Inspection and quality control

[top]External links

- British Coatings Federation

- Galvanizers Association

- Paint Research Association

- The Thermal Spraying and Surface Engineering Association