Difference between revisions of "River Usk Crossing"

| Line 1: | Line 1: | ||

| − | {{#image_template:image=File:River_Usk_Bridge.jpg|caption=''(Image courtesy of | + | {{#image_template:image=File:River_Usk_Bridge.jpg|caption=''(Image courtesy of Tata Steel)'' |align=right|wrap=true|width=500}} |

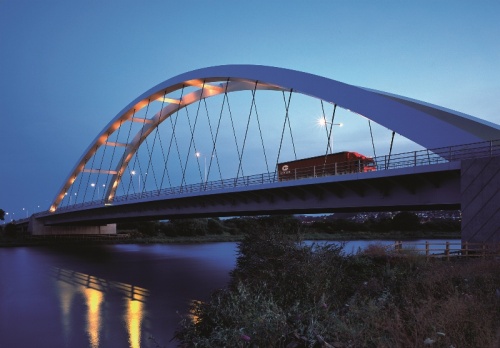

This landmark [[Tied-arch bridges|bowstring arch]] with a clear span of 187m combines elegant design, high quality [[Design for steel bridge construction#Fabricating the steelwork|fabrication]] and innovative construction. Durability was a key issue from the outset and external surfaces of all steelwork were treated with a high performance epoxy-based [[Paint coatings|paint system]]. The [[Box girder bridges|box section]] arch members were fabricated from [[Weathering steel|weathering steel]] and left unpainted internally, which avoided the significant [[Health and safety|health and safety]] issues associated with the initial painting and future maintenance painting inside confined spaces. A further innovation was the use of full depth precast slab units to form the steel composite deck. This assisted in controlling the steelwork geometry during construction, and minimised cracking of the slab. | This landmark [[Tied-arch bridges|bowstring arch]] with a clear span of 187m combines elegant design, high quality [[Design for steel bridge construction#Fabricating the steelwork|fabrication]] and innovative construction. Durability was a key issue from the outset and external surfaces of all steelwork were treated with a high performance epoxy-based [[Paint coatings|paint system]]. The [[Box girder bridges|box section]] arch members were fabricated from [[Weathering steel|weathering steel]] and left unpainted internally, which avoided the significant [[Health and safety|health and safety]] issues associated with the initial painting and future maintenance painting inside confined spaces. A further innovation was the use of full depth precast slab units to form the steel composite deck. This assisted in controlling the steelwork geometry during construction, and minimised cracking of the slab. | ||

Revision as of 11:59, 12 March 2019

This landmark bowstring arch with a clear span of 187m combines elegant design, high quality fabrication and innovative construction. Durability was a key issue from the outset and external surfaces of all steelwork were treated with a high performance epoxy-based paint system. The box section arch members were fabricated from weathering steel and left unpainted internally, which avoided the significant health and safety issues associated with the initial painting and future maintenance painting inside confined spaces. A further innovation was the use of full depth precast slab units to form the steel composite deck. This assisted in controlling the steelwork geometry during construction, and minimised cracking of the slab.

| Architect | Yee Associates |

| Structural Engineer | Aecom |

| Steelwork Contractor | Mabey Bridge Ltd. |

| Main Contractor | Morgan-Vinci |

| Client | Newport City Council |

Click here for more details of this project