Difference between revisions of "Metallic coatings"

| Line 63: | Line 63: | ||

The exposed surfaces of bolts, nuts and washers need to be protected to at least the same level as the primary members of steelwork. Hence, the full coating system should be applied after assembly of the bolted joint. However, bolts, nuts and washers need some short-term [[Corrosion protection|corrosion protection]] during the construction period until the full coating system is applied. This normally takes the form of a metallic coating applied during manufacture of the components. The recommended approach is to specify hot-dip galvanized bolts, nuts and washers, as this provides the highest level of corrosion protection with a considerably thicker coating than either sherardizing or electroplating. | The exposed surfaces of bolts, nuts and washers need to be protected to at least the same level as the primary members of steelwork. Hence, the full coating system should be applied after assembly of the bolted joint. However, bolts, nuts and washers need some short-term [[Corrosion protection|corrosion protection]] during the construction period until the full coating system is applied. This normally takes the form of a metallic coating applied during manufacture of the components. The recommended approach is to specify hot-dip galvanized bolts, nuts and washers, as this provides the highest level of corrosion protection with a considerably thicker coating than either sherardizing or electroplating. | ||

| − | The number of edges and potential crevices at bolted joints make them particularly vulnerable to corrosion. Hence, the Highways | + | The number of edges and potential crevices at bolted joints make them particularly vulnerable to corrosion. Hence, the National Highways' Specification for Highway Works (SHW) <ref name=”No5”> [http://www.standardsforhighways.co.uk/ha/standards/mchw/vol1/pdfs/series_1900.pdf Manual of Contract Documents for Highway Works: Volume 1 - Specification for Highway Works, Series 1900 Protection of steelwork against corrosion, August 2014, The Stationery Office] </ref> requires [[Paint coatings#Stripe coats|stripe coats]] to be applied to all exposed surfaces of bolts, nuts and washers. |

For further information on the protective treatment of bolts, refer to Steel Bridge Group [[#Resources|Guidance Note GN 8.02]]. | For further information on the protective treatment of bolts, refer to Steel Bridge Group [[#Resources|Guidance Note GN 8.02]]. | ||

Revision as of 15:45, 1 February 2022

There are four commonly used methods of applying metal coating to steel surfaces. These are hot-dip galvanizing, thermal spraying, electroplating and sherardizing. The latter two processes are not used for structural steelwork but are used for fittings, fasteners and other small items. In general the corrosion protection afforded by metallic coatings is largely dependent upon the choice of coating metal and its thickness and is not greatly influenced by the method of application.

[top]Hot-dip galvanizing

| The Galvanizing Process (Video courtesy of Highland Metals Ltd) |

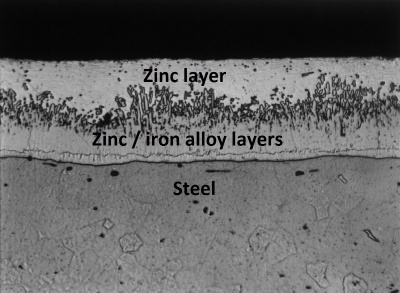

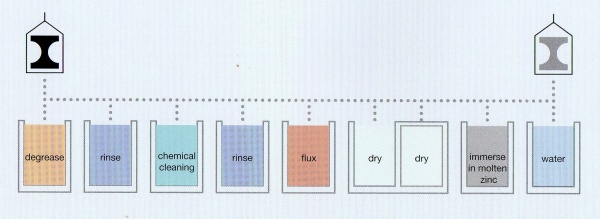

Hot-dip galvanizing is a process that involves immersing the steel component to be coated in a bath of molten zinc (at about 450°C) after pickling and fluxing, and then withdrawing it. The immersed surfaces are uniformly coated with zinc alloy and zinc layers that form a metallurgical bond with the substrate. The resulting coating is durable, tough, abrasion resistant, and provides cathodic (sacrificial) protection to any small damaged areas where the steel substrate is exposed.

As the zinc solidifies, it usually assumes a crystalline metallic lustre, often referred to as spangling. The thickness of the galvanized coating is influenced by various factors including the size and thickness of the workpiece, the steel surface preparation, and the chemical composition of the steel. The typical minimum average coating thickness for structural steelwork is 85 µm. Thick steel parts and steels which have been abrasive blast cleaned tend to produce relatively thick coatings up to 140 µm.

Since hot-dip galvanizing is a dipping process, there is obviously some limitation on the size of components that can be galvanized. However, ‘double-dipping’ can often be used when the length or width of the workpiece exceeds the size of the bath. The longest tank in the UK is currently 21 metres in length, the maximum double-dip dimension is 28 metres, and the maximum lift weight is 16 tonnes.

Some aspects of the design of structural steel components need to take the galvanizing process into account, particularly with regards the ease of filling, venting and draining and the likelihood of distortion. To enable a satisfactory coating, suitable holes must be provided in hollow to allow access for the molten zinc, the venting of hot gases, and the subsequent draining of zinc. Further guidance on the design of articles to be hot-dip galvanized can be found in BS EN ISO 14713-1[1], and the video below.

The suitability of steels for hot-dip galvanizing should also be considered. Structural steel that is to be hot-dip galvanized should be clearly specified, by invoking the appropriate options in the material standards, e.g. Option 5 in BS EN 10025-1[2].

It is known that on very rare occasions, hot dip galvanized steel work has produced cracking as a result of what has been identified as Liquid Metal Assisted Cracking (LMAC). The factors contributing to this effect should be appreciated and considered. These include the design and detailing of the component, condition and quality of the steel, fabrication and the galvanizing process. Published guidance is available that describes the phenomenon and gives guidance how to minimise the risk of occurrence.

The specification of hot-dip galvanized coating for structural steelwork is covered by BS EN ISO 1461[3].

For many applications, hot-dip galvanizing is used without further protection. However, to provide extra durability, or where there is a decorative requirement, paint coatings are applied. The combination of metal and paint coatings is usually referred to as a 'duplex' coating. When applying paints to galvanized coatings, special surface preparation treatments must be used to ensure good adhesion. These include light blast cleaning to roughen the surface and provide a mechanical key, and the application of special etch primers or 'T' wash, which is an acidified solution designed to react with the surface and provide a visual indication of effectiveness.

For further information on hot-dip galvanizing, refer to:

- Steel Bridge Group Guidance Note GN 8.03

- The Engineer's and Architect's Guide: Hot-dip Galvanizing

Design for Galvanizing

(Video courtesy of Highland Metals Ltd)

[top]Thermally sprayed metal coatings

Thermally sprayed coatings of zinc, aluminium, and zinc-aluminium alloys provide long-term corrosion protection to steel structures exposed to aggressive environments. They are an important component of coating systems that are currently specified by Network Rail and they are commonly used on steel bridge decks prior to surfacing with mastic asphalt systems.

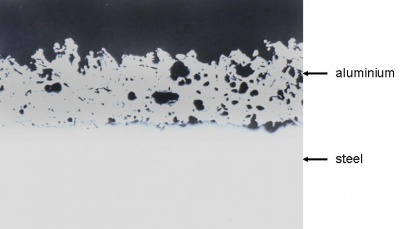

For bridge components, thermally sprayed aluminium is usually preferred and it acts as a barrier coating. However, for rail bridges likely to be subjected to collision damage, zinc is often preferred due to its sacrificial nature.

The metal, in powder or wire form, is fed through a special spray gun containing a heat source, which can be either an oxygas flame or an electric arc. Molten globules of the metal are blown by a compressed air jet onto the previously grit blast cleaned steel surface. No alloying occurs and the coating consists of overlapping platelets of metal and is porous. The adhesion of sprayed metal coatings to steel surfaces is considered to be essentially mechanical in nature. It is therefore necessary to apply the coating to a clean roughened surface and blast cleaning with coarse grit abrasive is normally specified.

Flame spraying aluminium coating

(Video courtesy of Metallisation)

Arc spraying aluminium coating

(Video courtesy of Metallisation)

The pores are subsequently sealed by applying a thin organic coating, which penetrates into the surface. Sealers may be either un-pigmented, with colouring agents or aluminium flake. Typically specified coating thicknesses vary between 100-200 µm (microns) for aluminium and 100-150 µm for zinc.

Thermally sprayed metal coatings can be applied in the shop or at site. No drying time is required, they do not sag or run, and can be applied to the required thickness in a single operation. There is no limitation on the size of the workpiece that can be coated, as there is with hot-dip galvanizing, and since the steel surface remains cool, there are no distortion problems. Guidance on the design of articles to be thermally sprayed can be found in BS EN ISO 14713-1[1]. Thermal spraying is considerably more expensive than hot-dip galvanizing.

For some applications (e.g. bridges), thermal spray coatings are over-coated with paint coatings (after the application of a sealer coating) to form a ‘duplex’ coating system. The combination of metal and paint in a duplex protective treatment has greater durability in comparison with that of the individual components.

The protection of structural steelwork against atmospheric corrosion by thermal sprayed aluminium or zinc coatings is covered in BS EN ISO 2063-1[4] and BS EN ISO 2063-2[5].

For further information on thermally sprayed metal coatings, refer to Steel Bridge Group Guidance Note GN 8.04.

[top]Protective treatment of fasteners

The exposed surfaces of bolts, nuts and washers need to be protected to at least the same level as the primary members of steelwork. Hence, the full coating system should be applied after assembly of the bolted joint. However, bolts, nuts and washers need some short-term corrosion protection during the construction period until the full coating system is applied. This normally takes the form of a metallic coating applied during manufacture of the components. The recommended approach is to specify hot-dip galvanized bolts, nuts and washers, as this provides the highest level of corrosion protection with a considerably thicker coating than either sherardizing or electroplating.

The number of edges and potential crevices at bolted joints make them particularly vulnerable to corrosion. Hence, the National Highways' Specification for Highway Works (SHW) [6] requires stripe coats to be applied to all exposed surfaces of bolts, nuts and washers.

For further information on the protective treatment of bolts, refer to Steel Bridge Group Guidance Note GN 8.02.

[top]Relevant Steel for Life sponsors

This website is maintained by Steel for Life with funding provided by a number of BCSA’s Industry Members. Those sponsors relevant to this article are as follows:

[top]References

- ↑ 1.0 1.1 BS EN ISO 14713-1: 2017, Zinc coatings. Guidelines and recommendations for the protection against corrosion of iron and steel in structures. General principles of design and corrosion resistance. BSI

- ↑ BS EN 10025-1: 2004, Hot rolled products of structural steels, General technical delivery conditions. BSI

- ↑ BS EN ISO 1461: 2009, Hot dip galvanized coatings on fabricated iron and steel articles. Specifications and test methods. BSI

- ↑ BS EN ISO 2063-1: 2017, Thermal spraying. Zinc, aluminium and their alloys. Design considerations and quality requirements for corrosion protection systems. BSI

- ↑ BS EN ISO 2063-2: 2017, Thermal spraying. Zinc, aluminium and their alloys. Execution of corrosion protection systems. BSI

- ↑ Manual of Contract Documents for Highway Works: Volume 1 - Specification for Highway Works, Series 1900 Protection of steelwork against corrosion, August 2014, The Stationery Office

[top]Resources

- Hendy, C.R.; Iles, D.C. (2015) Steel Bridge Group: Guidance Notes on best practice in steel bridge construction (6th Issue). (P185). SCI

- Steel Buildings, 2003, The British Constructional Steelwork Association Ltd.

- Chapter 12 – Corrosion Protection

- Galvanizing Structural Steelwork – An Approach to the Management of Liquid Metal Assisted Cracking (2005), Publication 40/05 BCSA & GA

[top]Further reading

- D.Deacon & R.Hudson (2012), Steel Designer’s Manual (7th Edition), Chapter 36 - Corrosion and corrosion prevention, The Steel Construction Institute.

- D.A. Bayliss & D.H.Deacon (2002), Steelwork Corrosion Control (2nd edition), Spon Press.

- The Engineer's and Architect's Guide: Hot-dip Galvanizing, The Galvanizer's Association, 2007

[top]See also

- Corrosion of structural steel

- Influence of design on corrosion

- Surface preparation

- Paint coatings

- Standard corrosion protection systems for buildings

- Appropriate specifications

- Inspection and quality control