Difference between revisions of "Inspection and quality control"

m |

|||

| (4 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

__SECTIONLINKTOTOP__ | __SECTIONLINKTOTOP__ | ||

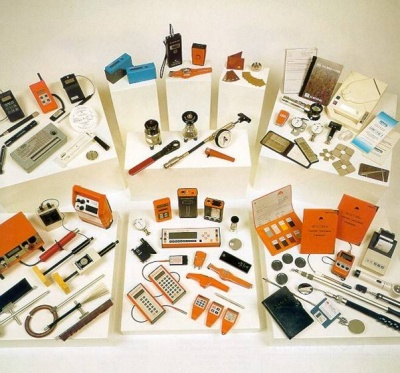

| + | {{#image_template:image=File:instruments.jpg|caption= Range of testing and inspection equipment |align=right|wrap=true|width=400}} | ||

Inspection forms an integral part of quality control. Its purpose is to check that the requirements of the [[Appropriate_specifications|specification]] are being complied with and to provide a report with proper records to the client. | Inspection forms an integral part of quality control. Its purpose is to check that the requirements of the [[Appropriate_specifications|specification]] are being complied with and to provide a report with proper records to the client. | ||

| − | + | ||

One of the greatest assets to the coating inspector is a clear written [[Appropriate_specifications|specification]] that can be referred to without doubt. | One of the greatest assets to the coating inspector is a clear written [[Appropriate_specifications|specification]] that can be referred to without doubt. | ||

The appointment of an appropriately qualified third party inspector should be seen as an investment in quality and not just an additional cost. Inspection of the processes, procedures and materials required for the protective coating of steel structures is vital, since a major error in even one operation cannot be easily detected after the next operation has been carried out, and if not rectified immediately can significantly reduce the expected life to first maintenance. | The appointment of an appropriately qualified third party inspector should be seen as an investment in quality and not just an additional cost. Inspection of the processes, procedures and materials required for the protective coating of steel structures is vital, since a major error in even one operation cannot be easily detected after the next operation has been carried out, and if not rectified immediately can significantly reduce the expected life to first maintenance. | ||

| Line 14: | Line 15: | ||

Similarly, the [[Surface_preparation#Site_painting_considerations|treatment of specific]] surfaces e.g. welds, edges and holes, etc. should be inspected to a suitable condition to receive the protective coating. Immediately before the application of the protective coating, a final check should be carried out to ensure that the surface is free from [[Surface_preparation#Surface_dust|dust]] and loose particulate matter and has not been re-contaminated. | Similarly, the [[Surface_preparation#Site_painting_considerations|treatment of specific]] surfaces e.g. welds, edges and holes, etc. should be inspected to a suitable condition to receive the protective coating. Immediately before the application of the protective coating, a final check should be carried out to ensure that the surface is free from [[Surface_preparation#Surface_dust|dust]] and loose particulate matter and has not been re-contaminated. | ||

| − | [[Paint_coatings|Paint]] types and qualities should be checked and there is normally a set procedure required by | + | [[Paint_coatings|Paint]] types and qualities should be checked and there is normally a set procedure required by Highways England and Network Rail to test the quality of ‘as delivered’ material and material being applied to the structure. The [[Paint_coatings#Application_of_paint_coatings|application process]] and prevailing conditions for both shop and site applications need to be checked along with the specified wet and dry film thicknesses. There is sometimes a requirement to check adhesion especially of [[Metallic_coatings#Thermally_sprayed_metal_coatings|thermally sprayed coatings]]. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {{#youtube:width=500px|height=280px|id=A1QnnGeyuYQ}}<br> | |

| + | '''Wet film thickness testing'''<br>''(Video courtesy of Corrodere/MPI)'' | ||

| − | Dry film thickness testing<br>''(Video courtesy of Corrodere/MPI)'' | + | {{#youtube:width=500px|height=280px|id=j9C3jAF-xUg}}<br> |

| + | '''Dry film thickness testing'''<br>''(Video courtesy of Corrodere/MPI)'' | ||

[[Metallic_coatings|Metal coatings]], including [[Metallic_coatings#Thermally_sprayed_metal_coatings|thermally sprayed coatings]] and [[Metallic_coatings#Hot-dip_galvanizing|hot dip galvanizing]], should be checked for adequate preparation if they are to be over-painted. | [[Metallic_coatings|Metal coatings]], including [[Metallic_coatings#Thermally_sprayed_metal_coatings|thermally sprayed coatings]] and [[Metallic_coatings#Hot-dip_galvanizing|hot dip galvanizing]], should be checked for adequate preparation if they are to be over-painted. | ||

Latest revision as of 19:40, 12 March 2019

Inspection forms an integral part of quality control. Its purpose is to check that the requirements of the specification are being complied with and to provide a report with proper records to the client.

One of the greatest assets to the coating inspector is a clear written specification that can be referred to without doubt. The appointment of an appropriately qualified third party inspector should be seen as an investment in quality and not just an additional cost. Inspection of the processes, procedures and materials required for the protective coating of steel structures is vital, since a major error in even one operation cannot be easily detected after the next operation has been carried out, and if not rectified immediately can significantly reduce the expected life to first maintenance.

[top]General

Inspection should commence at the initial stages, for without control to ensure a properly treated substrate, the value of subsequent operations is reduced. Good surface preparation is the foundation for durability and should not be underestimated.

Before abrasive blast cleaning to remove millscale and rust, the surface should be visually free from oil, grease and other contaminants. After the removal of millscale and rust, it is necessary to check that the required level of cleanliness and surface profile have been achieved by reference to the relevant standards.

Similarly, the treatment of specific surfaces e.g. welds, edges and holes, etc. should be inspected to a suitable condition to receive the protective coating. Immediately before the application of the protective coating, a final check should be carried out to ensure that the surface is free from dust and loose particulate matter and has not been re-contaminated.

Paint types and qualities should be checked and there is normally a set procedure required by Highways England and Network Rail to test the quality of ‘as delivered’ material and material being applied to the structure. The application process and prevailing conditions for both shop and site applications need to be checked along with the specified wet and dry film thicknesses. There is sometimes a requirement to check adhesion especially of thermally sprayed coatings.

Wet film thickness testing

(Video courtesy of Corrodere/MPI)

Dry film thickness testing

(Video courtesy of Corrodere/MPI)

Metal coatings, including thermally sprayed coatings and hot dip galvanizing, should be checked for adequate preparation if they are to be over-painted. Thermally sprayed coatings should be sealed immediately after application to avoid the formation of corrosion products from the coating material or, especially in the case of aluminium, the appearance of red rust from the substrate. The use of a mordant ('T-wash') treatments to hot dip galvanized coatings should be monitored to ensure that the application is consistent with the manufacturers’ data sheets and that the treatment has been effective with the treated surface free from residual solution and made thoroughly dry.

Records of all aspects of inspection along with any problems should be made and any departure from the specified process noted.

The appointment of a suitably qualified inspector should be regarded as an important part of the job. Those involved with such duties should have been trained in internationally recognised practices and standards and be in possession of the appropriate certification. Such a scheme is available through The Institute of Corrosion in the UK. This international scheme is available for the qualification and certification of industrial painting and coating inspectors and operates in accordance with EN ISO/IEC 17024[1]

For further information on the inspection of surface preparation and coating treatments, refer to Steel Bridge Group Guidance Note GN 8.06.

[top]References

- ↑ BS EN ISO/IEC 17024: 2012 Conformity Assessment. General requirements for bodies operating certification of persons. BSI

[top]Resources

- Hendy, C.R.; Iles, D.C. (2015) Steel Bridge Group: Guidance Notes on best practice in steel bridge construction (6th Issue). (P185). SCI

- Steel Buildings, 2003, The British Constructional Steelwork Association Ltd.

- Chapter 12 – Corrosion Protection

[top]Further reading

- D.Deacon & R.Hudson (2012), Steel Designer’s Manual (7th Edition), Chapter 36 - Corrosion and corrosion prevention, The Steel Construction Institute.

- D.A. Bayliss & D.H.Deacon (2002), Steelwork Corrosion Control (2nd edition), Spon Press.

[top]See also

- Corrosion of structural steel

- Influence of design on corrosion

- Surface preparation

- Paint coatings

- Standard corrosion protection systems for buildings

- Metallic coatings

- Appropriate specifications