Difference between revisions of "Hollow sections in fire"

| Line 37: | Line 37: | ||

==Reducing [[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|thin film intumescent coating]] thickness on hollow sections by design== | ==Reducing [[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|thin film intumescent coating]] thickness on hollow sections by design== | ||

| − | The thickness of [[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|thin film intumescent coatings]] on [[Steel_construction_products#Structural_hollow_sections|structural hollow section]] columns is usually based on a [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] | + | The thickness of [[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|thin film intumescent coatings]] on [[Steel_construction_products#Structural_hollow_sections|structural hollow section]] columns is usually based on a [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] and the [[Calculating_section_factors|section factor]]. However, if it can be shown that the column is not fully loaded, the [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] may be increased and the coating thickness reduced. Most manufacturers of have data to support this and will supply the required thicknesses if an alternative [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] is given. |

| − | For example, take the 244.5 x 14.2 CHS described above. For 90 minutes [[Structural_fire_resistance_requirements|fire resistance]], using a | + | For example, take the 244.5 x 14.2 CHS described above. For 90 minutes [[Structural_fire_resistance_requirements|fire resistance]], using a typical [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] of 550°C, the coating thickness, averaged over a range of products, is 2628μm. However, if the column is loaded to 83% in the normal condition (a [[Design_using_structural_fire_standards#Effect_of_load|load ratio]] of 0.5 in the fire condition) of its capacity then, according to [[Design_using_structural_fire_standards#BS_5950_Part_8|BS 5950 Part 8]]<ref name="No1"> BS 5950-8: 2003, Structural use of steelwork in buildings. Code of practice for fire resistant design. BSI</ref> the [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] increases considerably. This can result in a significant reduction in the required coating thickness. |

| − | This approach can be extended by examining the potential for redesigning the column. Take again the 244.5 x 14.2 CHS and assume it to be fully loaded with a coating thickness of 2628μm. The column can be replaced by a 244.5 x 16 CHS, which keeps the footprint constant while decreasing the [[Calculating_section_factors|section factor]] and increasing the | + | This approach can be extended by examining the potential for redesigning the column. Take again the 244.5 x 14.2 CHS and assume it to be fully loaded with a coating thickness of 2628μm. The column can be replaced by a 244.5 x 16 CHS, which keeps the footprint constant while decreasing the [[Calculating_section_factors|section factor]] and increasing the axial resistance. |

| − | The change has the effect of decreasing the [[Calculating_section_factors|section factor]] to 65m<sup>-1</sup> and, over a 4m length, increasing the | + | The change has the effect of decreasing the [[Calculating_section_factors|section factor]] to 65m<sup>-1</sup> and, over a 4m length, increasing the axial resistance from 3190kN to 3560kN. The impact of increasing the load carrying capacity is to reduce the [[Design_using_structural_fire_standards#Effect_of_load|load ratio]] and increase the [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] by over 40°C. Combined, this decrease in [[Calculating_section_factors|section factor]] and increase in [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperature]] reduces the coating thickness of 2628μm to around 1300μm. |

Similar calculations on [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperatures]] can be carried out for columns using [[Design_using_structural_fire_standards#Fire_Eurocodes|BS EN 1993-1-2]]<ref name="No2"> BS EN 1993-1-2. 2005, Eurocode 3. Design of steel structures. General rules. Structural fire design. BSI</ref> (called critical temperature,θ<sub>a,cr</sub>, in that standard). These are provided in terms of what is called the utilization factor, μ<sub>0</sub>, (the Eurocode equivalent of [[Design_using_structural_fire_standards#Effect_of_load|load ratio]]). | Similar calculations on [[Design_using_structural_fire_standards#Steelwork_strength_in_fire|limiting temperatures]] can be carried out for columns using [[Design_using_structural_fire_standards#Fire_Eurocodes|BS EN 1993-1-2]]<ref name="No2"> BS EN 1993-1-2. 2005, Eurocode 3. Design of steel structures. General rules. Structural fire design. BSI</ref> (called critical temperature,θ<sub>a,cr</sub>, in that standard). These are provided in terms of what is called the utilization factor, μ<sub>0</sub>, (the Eurocode equivalent of [[Design_using_structural_fire_standards#Effect_of_load|load ratio]]). | ||

| − | + | In general, the smaller the section (and usually therefore, the higher the [[Calculating_section_factors|section factor]] and the thicker the coating) and the longer the [[Structural_fire_resistance_requirements|fire resistance period]] required, the more likely it is that considering a heavier hollow section of the same size will be worthwhile. It will however be a balance between a number of factors. The most important of these is the relationship between the cost of application of the [[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|intumescent coating]] and the added cost of the steel. It is worth being aware also that there is a maximum coating thickness that can be applied in a single application and that cost of application of [[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|intumescent coatings]] is a function of the number of coats required. It follows that in some instances a relatively small decrease in coating thickness can reduce the number of applications required and lead to a significant reduction in cost. | |

==Concrete filled and reinforced structural hollow sections== | ==Concrete filled and reinforced structural hollow sections== | ||

Revision as of 14:58, 21 June 2022

(Image courtesy of Sherwin-Williams Protective and Marine Coatings)

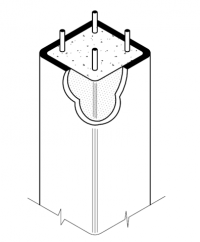

Structural hollow sections provide architects and engineers with aesthetically pleasing and structurally efficient solutions. Hollow sections have a constant external dimension for all weights of a given size, which enables them to achieve standardisation of architectural and structural details throughout the full height of the building. The uniformity of shape and properties means that they more are efficient in certain design conditions than open sections. Fire resistance in structural hollow sections can be achieved by the use of:

- External fire protection, usually thin film intumescent coatings

- Concrete filling with reinforcement

- Concrete filling combined with external fire protection.

This article examines all three approaches.

[top]Fire protecting structural hollow sections

(Image courtesy of Nuvia)

The most common form of fire protection for structural hollow sections is thin film intumescent coatings, although thick film epoxy intumescents in the form of preformed casings have also been used in external situations or internal situations where atmospheric conditions are too severe or concerns about damage are too great to allow the use of thin film coatings. The thickness of structural fire protection is usually based on the section factor of the hollow section. Typically the thickness of thin film intumescent coating required for a hollow section is greater than for an open column section with the same resistance. The thicker coating is balanced by the reduced surface area of a hollow section, compared to an open profile.

| 305 x 305 UC 97 Grade S355 |

244.5 x 14.2 CHS Grade S355 | |

|---|---|---|

| Length (m) | 4 | 4 |

| Buckling capacity (kN) | 3220 | 3190 |

| Section factor, 4-sided exposure (m-1) | 146 | 75 |

| Thickness of typical on-site applied thin film intumescent coating (μm) 60 minutes fire resistance |

457a | 599a |

| Thickness of typical on-site applied thin film intumescent coating (μm) 90 minutes fire resistance |

1418a | 2628a |

| Surface area (m2) | 7.16 | 3.07 |

a Data taken as the average of a number of different products in February 2013

[top]Reducing thin film intumescent coating thickness on hollow sections by design

The thickness of thin film intumescent coatings on structural hollow section columns is usually based on a limiting temperature and the section factor. However, if it can be shown that the column is not fully loaded, the limiting temperature may be increased and the coating thickness reduced. Most manufacturers of have data to support this and will supply the required thicknesses if an alternative limiting temperature is given. For example, take the 244.5 x 14.2 CHS described above. For 90 minutes fire resistance, using a typical limiting temperature of 550°C, the coating thickness, averaged over a range of products, is 2628μm. However, if the column is loaded to 83% in the normal condition (a load ratio of 0.5 in the fire condition) of its capacity then, according to BS 5950 Part 8[1] the limiting temperature increases considerably. This can result in a significant reduction in the required coating thickness.

This approach can be extended by examining the potential for redesigning the column. Take again the 244.5 x 14.2 CHS and assume it to be fully loaded with a coating thickness of 2628μm. The column can be replaced by a 244.5 x 16 CHS, which keeps the footprint constant while decreasing the section factor and increasing the axial resistance. The change has the effect of decreasing the section factor to 65m-1 and, over a 4m length, increasing the axial resistance from 3190kN to 3560kN. The impact of increasing the load carrying capacity is to reduce the load ratio and increase the limiting temperature by over 40°C. Combined, this decrease in section factor and increase in limiting temperature reduces the coating thickness of 2628μm to around 1300μm.

Similar calculations on limiting temperatures can be carried out for columns using BS EN 1993-1-2[2] (called critical temperature,θa,cr, in that standard). These are provided in terms of what is called the utilization factor, μ0, (the Eurocode equivalent of load ratio).

In general, the smaller the section (and usually therefore, the higher the section factor and the thicker the coating) and the longer the fire resistance period required, the more likely it is that considering a heavier hollow section of the same size will be worthwhile. It will however be a balance between a number of factors. The most important of these is the relationship between the cost of application of the intumescent coating and the added cost of the steel. It is worth being aware also that there is a maximum coating thickness that can be applied in a single application and that cost of application of intumescent coatings is a function of the number of coats required. It follows that in some instances a relatively small decrease in coating thickness can reduce the number of applications required and lead to a significant reduction in cost.

[top]Concrete filled and reinforced structural hollow sections

By filling hollow sections with concrete, a composite section is produced which will increase the section’s room temperature load carrying capacity, whilst retaining all the advantageous features of the basic unfilled section. Alternatively, for the same original load capacity, it permits smaller composite sections to be used. Any reduction in section size also gives advantages in subsequent construction processes, including a reduced surface area for painting and a reduced footprint (and increased lettable area). Filled hollow sections will need to contain reinforcement in the mix in order to minimise column dimensions and to sustain the required fire limit state design loads for fire resistance periods of 60 minutes or more.

Design guidance and software (Firesoft) for the design of reinforced, concrete filled hollow sections in fire is available. The software is based on the European code for composite construction for ambient conditions, BS EN 1994-1-1[3], the main difference between ambient and fire designs being the modifications of mechanical properties at elevated temperatures for the fire conditions.

[top]Concrete filled hollow sections with external fire protection

There will be occasions, particularly where the column is subjected to moments, when the most economical solution to the design of a fire resistant concrete filled hollow section will be to design for maximum structural efficiency and to obtain the required fire resistance by the application of a conventional fire protection material, usually a thin film intumescent coating. The presence of the concrete core acts as a heat sink and enables reductions in the protection thickness to be made compared to a similar unfilled section. For passive fire protection materials such as boards and sprays, BS 5950 Part 8[1] , Section 8.6.2 contains fire protection thickness modification factors. These are not suitable for reactive materials such as intumescent coatings. A paper published by Tata Steel (then British Steel) in 1998[4] quantified the impact of concrete filling when using thin film intumescent coatings in terms of an effective section factor.

The Effective section factor for a circular hollow section of external diameter D can be defined as:

(Am/V)e = 1/[(ts + tce)*[1 - (ts + tce)/D]

Where:

tce = apparent increase in wall thickness due to the presence of the concrete.

The value of tce is time dependent and has been quantified to a high accuracy for filled CHS as:

either

tce = 1.858T0.5 when di > 24.717T0.5

or

tce = 0.1206di[2 – di /(17.955T0.5)] when di ≤ 24.717T0.5

where:

T = the heating time in the standard fire test in minutes

di = the internal CHS diameter in mm

An alternative set of expressions have been developed for square hollow sections:

either:

tce = 1.810T0.5 when bi > 20.972T0.5

or:

tce = 0.1193bi[2 – bi /(16.422T0.5)] when bi ≤ 20.972T0.5

where:

T = the heating time in the standard fire test in minutes

bi = the internal dimension size in mm

The thickness of a thin film intumescent coating required for a given fire resistance period when filled with concrete can be calculated on the basis of the effective section factor.

Recent research carried out by a leading intumescent coating manufacturer and the University of Edinburgh indicates that these equations are generally conservative and in some cases may be very much so. It may well prove to be of value therefore to check the film thicknesses found using the equations with those available from a manufacturer who has carried out recent testing.

[top]Aesthetic finishes using thin film intumescent coatings

Because structural hollow sections are often chosen as a consequence of their superior aesthetic appearance, it follows that any applied fire protection will also be required to preserve an attractive finish. ASFP Technical Guidance Document 16[5] provides the following information on finishes for thin film intumescent coatings:

The quality of finishes falls under the following categories:

- Basic Finish The coating system achieves the required fire performance and corrosion protection performance, but is not required to achieve any requirement for standard of finish

- Decorative Finish In addition to the requirements for (1) above, a good standard of cosmetic finish is generally required, when viewed from a distance of 5m. Minor orange peel or other texture resulting from application or localised repair is acceptable

- Bespoke Finish In addition to the requirements for (2) above, the coating finish is required to have a standard of evenness, smoothness and gloss agreed between the Specifier and Contractor.

Application of thin film intumescent coatings for an aesthetic finish requires additional time and care over that required for non-aesthetic application. It is acknowledged that the skill of the applicator is a major factor in achieving an acceptable finish. Some applicators specialise in aesthetic application and it may be prudent to consult with the manufacturer for advice on this.

Providing aesthetic finishes to thin film intumescent coatings can be particularly difficult when using off-site application. It can, and has, been done but offers particular problems, mainly due to the fact that off-site applied coatings inevitably require some repair. It is difficult, but not of course impossible, to match the finish in areas that require repair with the finish in unaffected areas. The advice of the applicator should always be sought in these circumstances.

[top]Case Studies

[top]References

- ↑ 1.0 1.1 BS 5950-8: 2003, Structural use of steelwork in buildings. Code of practice for fire resistant design. BSI

- ↑ BS EN 1993-1-2. 2005, Eurocode 3. Design of steel structures. General rules. Structural fire design. BSI

- ↑ BS EN 1994-1-1:2004. Design of composite steel and concrete structures. General rules and rules for buildings BSI

- ↑ The performance in fire of concrete filled SHS columns protected by Intumescent paint. Edwards, M. 8th International Synposium on tubular structures. 26-28 August 1998. Singapore

- ↑ Association for Specialist Fire Protection Technical Guidance Document 16: 2010. Code of Practice for Off-site Applied Thin Film Intumescent Coatings

[top]Resources

- Steel construction - Fire Protection supplement, 2013

- NCCI: PN006a-GB Design of reinforced, concrete filled, hot finished structural steel hollow sections in fire

[top]See also

- Fire protecting structural steelwork

- Canculating section factors

- Structural fire resistance requirements