Target Zero

Target Zero was a programme of work to provide guidance on the design and construction of sustainable, low and zero carbon buildings in the UK. Five non-domestic building types were analysed: a large distribution warehouse, an out-of-town supermarket, a secondary school, a high-rise office block and a mixed-use (office and hotel) building. The project was completed in 2011.

At that time, Target Zero was the largest and most comprehensive study undertaken to date to assess and compare the sustainability performance of new non-domestic buildings in the UK. All building and alternative structural options, energy efficiency measures and renewable energy technologies studied were independently assessed and costed.

Target Zero was undertaken by a consortium of leading organisations in the field of sustainable construction: AECOM and The Sweett Group (now part of Currie & Brown) with steel construction expertise provided by Tata Steel Europe RD&T and the Steel Construction Institute (SCI).

Full results and guidance from the programme are freely available. This article provides a summary of the methodology, results and the key findings from the study.

- Target Zero Guides

[top]Target Zero methodology

Using typical buildings, all constructed just prior to the beginning of the project, as benchmarks, Target Zero investigated three specific, priority areas of sustainable construction:

- Operational carbon - how operational energy use and associated carbon emissions can be reduced by incorporating appropriate and cost-effective energy efficiency measures and low and zero carbon (LZC) technologies, and whether operational carbon emissions are influenced by alternative structural forms

- BREEAM assessments - how ‘Very Good’, ‘Excellent’ and ‘Outstanding’ BREEAM (2008) ratings could be achieved at lowest cost;

- Embodied carbon - quantification of the embodied carbon of buildings particularly focussing on different structural forms.

Full cost plans for each of the five buildings studied were developed by The Sweett Group (now part of Currie & Brown).

To provide a consistent benchmark, some minor modifications were made to the real buildings to make them equivalent, in terms of operational carbon performance, to the minimum requirements under Building Regulations Part L 2006. The modified buildings are referred to as the Base Case buildings.

It is important to note that the Target Zero methodology was developed in 2009 and, as such, is based on the state-of-the art and on regulations in place at that time. In particular, this included Appproved Document L2A (2006), BREEAM (2008), both of which have since been superseded.

[top]Target Zero buildings

The five buildings analysed are described below. Floor area and capital construction costs are also given.

| Building type and location | Description (base case building) | Gross Internal Floor area (GIFA) (m2) (Storeys) |

Capital construction cost (£k) [Pricing date] |

Unit capital construction cost (£/m2 GIFA) |

|---|---|---|---|---|

| Distribution warehouse, Stoke-on-Trent | Steel portal frame Built-up steel wall and roof cladding systems 15% rooflights Gas-fired radiant heating |

35,400 (single storey with 2-storey attached office block) |

19,441 [Q3 2009] |

549 |

| Supermarket, Stockton-on-Tees | Braced steel frame Upper floor (back of house) structural metal decking Mezzanine – plywood boarding on rolled steel joists Aluminium standing seam roof Composite steel panel external walls Completed in May 2008 |

9,393 (single storey with mezzanine front of house; two storey back of house) |

16,400 [Q4 2009] |

1,746 |

| Secondary school, Knowsley | Structural steel frame supporting precast concrete floor slabs A combination of timber cladding, aluminium curtain walling and terracotta rainscreen Mechanically ventilated Completed December 2008 |

9,637 (3 storeys) |

22,500 [Q2 2009] |

2,335 |

| Office, Central London | Fabricated cellular steel beams supporting a lightweight concrete slab on profiled steel decking Aluminium curtain walling Mechanically ventilated and cooled Completed in 2008 |

33,018 (10 storeys and 2 basement levels) |

61,700 [Q2 2010] |

1,869 |

| Mixed-use (hotel and office), Manchester | Steel frame with shallow floor system floors Aluminium curtain-walling and rainscreen, ceramic granite cladding and external render Mechanically ventilated and cooled Completed in 2011 |

18,625 (17 storeys) |

36,700 [Q4 2010] |

1,970 |

- Target Zero buildings

[top]Alternative structural forms

The five base case buildings were all steel-framed buildings. Two alternative viable structural options for four of the five buildings were identified and alternative designs were developed to RIBA Work Stage D; only one viable alternative structural form was identified for the commercial office building. These alternative structural options were then costed by The Sweett Group (now part of Currie & Brown). The alternative structural options considered for each of the five buildings studied and corresponding unit capital costs are shown.

| Building type and location | Base case structure | Alternative structural option 1 | Alternative structural option 2 | |||

|---|---|---|---|---|---|---|

| Description | Structurea unit cost (£/m2) | Description | Structurea unit cost (£/m2) | Description | Structurea unit cost (£/m2) | |

| Distribution warehouse, Stoke-on-Trent | Steel portal frame | 65 | Glulam beams and purlins supported on concrete columns | 118 | Steel portal frame with northlights | 85 |

| Supermarket, Stockton-on-Tees | Braced steel frame CFA piles |

107 | Glulam frame Upper floor concrete slab on steel deck Mezzanine: Glulam beams supporting timber decking CFA piles |

141 | Braced steel frame Upper floor concrete slab on metal deck Mezzanine: light steel supporting timber decking North light roof profile in retail area Steel H-piles |

117 |

| Secondary school, Knowsley | Steel frame supporting precast hollow core concrete units Precast concrete piles |

203 | In-situ 350mm concrete flat slab Precast concrete piles |

182 | Steel frame supporting a concrete slab on a profiled steel deck Steel H-piles |

190 |

| Office, Central London | Fabricated cellular steel beams supporting a lightweight concrete slab on a profiled steel deck | 316 | 350mm thick post-tensioned concrete flat slab | 377 | ||

| Mixed-use (hotel and office), Manchester | Steel frame with shallow floor system | 411 | Concrete flat slab: 260mm thick slab in office floors 250mm thick slab in hotel floors |

355 | Cellular steel beams supporting lightweight concrete slab on steel decking | 318 |

aFrame and upper floors

Cost model updates

In 2016, the BCSA and Steel for Life commissioned AECOM to provide impartial cost guidance applicable to a broad range of construction professionals. A key feature is a series of building type specific cost comparisons based on the same buildings that were originally part of the Target Zero study. These cost comparisons presented in the ‘Costing Steelwork’ series, published quarterly in Building magazine, update the cost models developed for the Target Zero project, and provide up-to-date costs for the alternative framing solutions considered for each of the five building types.

[top]Operational carbon assessment

A dynamic thermal model of each building was developed using the IES software suite and the model fine-tuned to just pass Building Regulations Part L (2006). For consistency, all five buildings were assessed using CIBSE Manchester 2005 weather tapes.

Dynamic thermal modelling was then used to predict the operational energy performance of each building following the introduction of a range of practicable energy efficiency measures and LZC technologies. The predicted energy costs, coupled with the capital and maintenance costs, were then used to derive a net present value (NPV) for each measure over a 25-year period. This period was selected to represent the maximum likely timescale after which full asset replacement would have to be considered for the LZC technologies analysed. NPVs were expressed as a deviation from that of the Base Case building, thus some energy efficiency measures and LZC technologies have negative NPVs as they were found to save money over the 25-year period considered.

The cost data and the energy modelling results were then combined to provide each energy efficiency measure and LZC technology with a cost-effectiveness measure in terms of 25-year NPV per kg of CO2 saved relative to the Base Case building performance. Energy efficiency measures and LZC technologies were then ranked in terms of this cost-effectiveness measure to derive the most cost effective routes, i.e. combinations of compatible energy efficiency and LZC technologies, to achieve 25%, 44%, 70% & 100% (BER=0) reductions in regulated carbon emissions (relative to Part L 2006) and true zero carbon (zero regulated and unregulated carbon emissions). Setting of these reduction targets predated the 2011 Government consultations[1] on policy options for new non-domestic buildings.

As part of this analysis, the impact of the different structural forms on operational carbon emissions was also modelled. Where relevant (office and mixed-use buildings) the buildings were modelled both with and without suspended ceilings. This was done to expose the soffits of the upper floors allowing the thermal mass in the floor slabs to be more effectively mobilised.

[top]Embodied carbon assessment

The embodied carbon impact of the five buildings and the alternative structural options considered was measured using the life-cycle assessment (LCA) model CLEAR.

CLEAR is based on the LCA standards BS EN ISO 14040[2] and 14044[3] and was developed by Tata Steel using the GaBi 4 software platform (now Sphera).

The CLEAR model has successfully undergone a third party critical review to the relevant ISO standards on LCA by Arup. This review concluded that the CLEAR methodology and its representation in the GaBi software (now Sphera) had been undertaken in accordance with the requirements of BS EN ISO 14040[2] and 14044[3]. Furthermore Arup were confident that the data quality rules used to select the material life cycle inventory data in the CLEAR GaBi model were also consistent with these standards and the goals of the methodology. The CLEAR model assumptions were also reviewed and approved by AECOM as part of the Target Zero study.

The scope of the embodied carbon assessment performed using the CLEAR model is shown.

| Life cycle stage | Description |

|---|---|

| Material/product manufacture | Included – see table below |

| Transport (factory gate to site) | Included – average gate-to-site transport distances for the UK were based on the Department for Transport’s (DfT) Road Freight Statistics. All transport was assumed to be by road with vehicles assumed to be loaded to 85% of capacity. Empty return trips were conservatively assumed. |

| Construction waste | Included – based on WRAP data |

| Transport of waste from site | Included as above |

| Construction process | Included - no specific data or information on construction site impacts was available for the five buildings studied. Instead information, in terms of diesel and electricity consumption data, from two published sources were used and these data scaled to the size (GIFA) of the buildings studied. Insufficient data were available to differentiate site construction impacts between the different structural options assessed |

| Maintenance | Excluded - maintenance regimes and their associated impacts for different structural options are not well documented nor are they likely to be significant for structure |

| Demolition/deconstruction | Excluded – insufficient data are currently available to quantify demolition impacts robustly |

| End-of-life recovery rates | Included – see below |

As the basis of the cost plans, bills of quantities were generated for all five buildings and each alternative structural form. These were then used to derive the material input quantities to the CLEAR model.

The main building elements were accounted for, including:

- Foundations and ground floor slab, including associated fill materials

- Superstructure (including all structural columns and beams, cladding rails and fire protection)

- Upper floors and staircases

- Walls (external and internal partition walls)

- Roof

- Windows, rooflights and glazed curtain walling

- Drainage

- External works (warehouse and supermarket studies only).

Items excluded from the analysis were access ladders and gantries, internal doors, internal fit-out, lifts, wall, floor and ceiling finishes and building services such as water, heating and cooling systems.

[top]Carbon emission factors

Most of the embodied carbon emission factors used in CLEAR were sourced from PE International’s ‘Professional’ and ‘Construction Materials’ GaBi databases. PE International (now Sphera) are leading experts in LCA and have developed many consistent material LCA databases.

Steel data were provided by the World Steel Association (worldsteel) based on 2000 average production data. The worldsteel LCA study[6] is regularly updated and is one of the largest and most comprehensive LCA studies undertaken. It has been independently reviewed to BS EN ISO standards 14040[2] and 14044[3].

Steel data from GaBi were not used because at the time some products, including structural steel sections, were not included within the GaBi databases. Since the Target Zero study ended, the worldsteel data have become available in GaBi.

The embodied carbon results were reported in terms of total greenhouse gas emissions in carbon dioxide equivalents (CO2e). In this study, an index of greenhouse gases developed by the University of Leiden[7] was used. This index had been updated with what were then the latest characterisation factors from the Intergovernmental Panel on Climate Change (IPCC).

The embodied carbon emission factors for the principal structural materials used in the assessments are shown. It should be noted that these are different to those to be found elsewhere on this site. That is because data changes over time as newer and better information becomes available.

| Material | Data source | End-of-life assumption | Source | Total lifecycle CO2 emissions (tCO2e/t) |

|---|---|---|---|---|

| Fabricated steel sections | worldsteel (2002) | 99% closed loop recycling, 1% landfill | MFA of the UK steel construction sector | 1.009 |

| Steel purlins | worldsteel (2002) | 99% closed loop recycling, 1% landfill | MFA of the UK steel construction sector | 1.317 |

| Steel reinforcement | worldsteel (2002) | 92% recycling, 8% landfill | MFA of the UK steel construction sector | 0.820 |

| Concrete (C30/37) | GaBi LCI database 2006 – PE International | 77% open loop recycling, 23% landfill | Department for Communities and Local Government | 0.139 |

| Glulam | GaBi LCI database 2006 – PE International | 16% recycling, 4% incineration, 80% landfill | TRADA | 1.10 |

[top]End-of-life impacts

The outcomes for materials from buildings after they are demolished can have a significant effect on whole lifecycle emissions. For example, assumptions made about the end-of-life disposal of bio-based products including their decomposition within landfill and any resulting methane emissions are significant and should be taken into account in a robust, whole-life embodied carbon assessment.

End-of-life data used in the CLEAR model were based on current material performance, using published data where these are available, rather than based on future possible end-of-life scenarios.

There is a range of methodologies that can be used to assess the benefits of recycling. The CLEAR model follows the guidelines for allocation procedures set out in BS EN ISO 14044[3] to calculate the benefits of recycling. Materials that are recycled are assumed to displace or save the production of new materials (which could be the same or a different material) and are given ‘credits’ equivalent to the impacts avoided. This approach was applied to all materials within the model.

Where one product system is recycled to form another product system with different inherent properties, this is known as open loop recycling. An example of this is crushing concrete to produce hardcore.

Other materials are capable of being recycled without loss of quality. This is known as closed loop recycling. An example of this is steel which is recycled (remelted) into new steel products without any loss of properties or quality.

The efficiency of recycling was set in the CLEAR model using an efficiency factor for each material, to reflect whether the material follows closed or open loop recycling characteristics. Efficiency factors can be calculated using methods outlined in LCA ISO standards, such as value correction or mass allocation. For materials that are closed-loop recycled, the efficiency factor is taken as 100% meaning that there is no loss of material property during recycling. For materials that are open-loop recycled, the efficiency factor is calculated to take account of the loss in properties incurred through the recycling process.

[top]BREEAM assessment

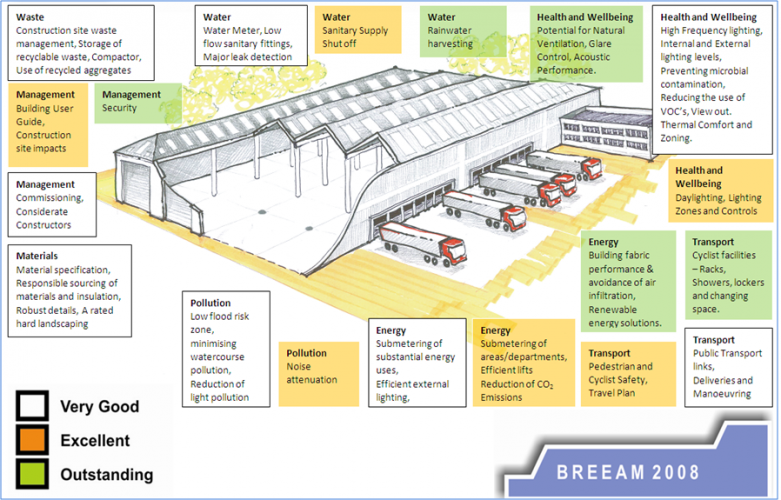

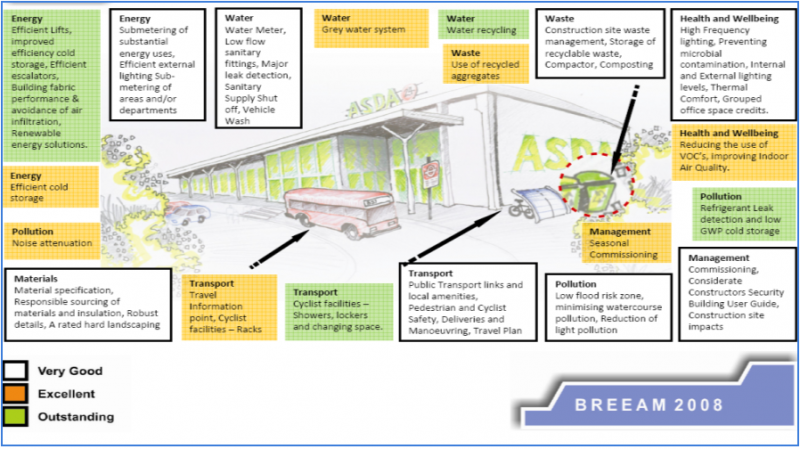

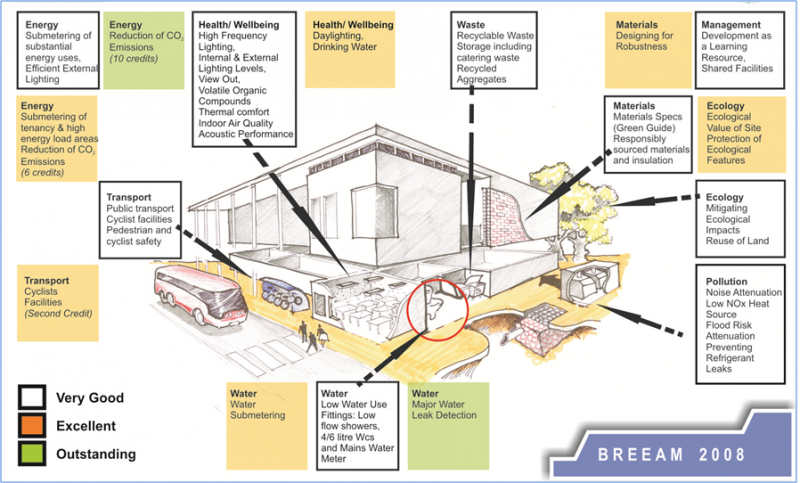

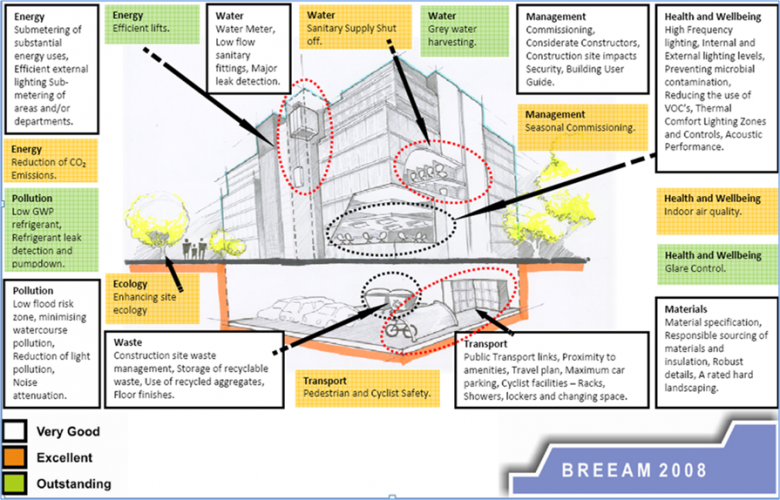

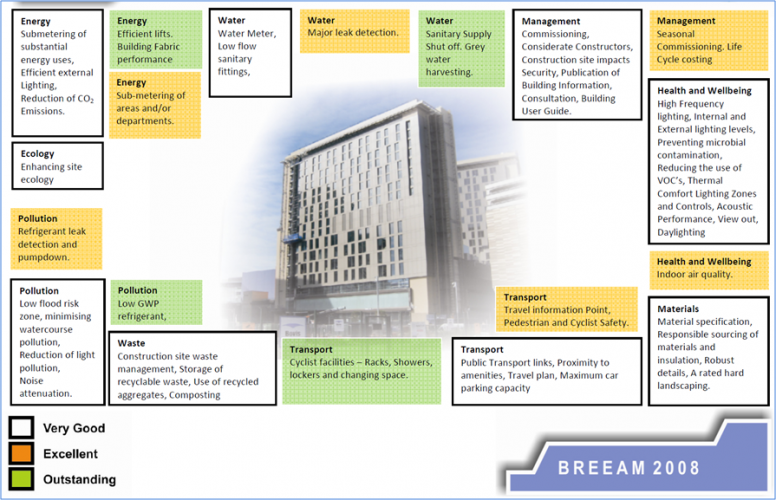

The objective of this aspect of Target Zero was to determine the most cost-effective routes to achieving a BREEAM (2008) ‘Very Good’, ‘Excellent’ and ‘Outstanding’ rating for each of the five buildings.

Base Case buildings were defined based on the specifications and locations given here and on typical construction practice. As for the operational carbon assessment, the Base Case buildings were compliant with the minimum requirements under Part L (2006).

Reflecting the influence of location and other factors on the achievable BREEAM score, different scenarios were modelled including different locations and site conditions and different design and contractor assumptions.

All the credits that required additional work to achieve were attributed with a capital cost and assigned a ‘weighted value’ by dividing the capital cost of achieving the credit, by its credit weighting. Credits were then ranked in order of cost-effectiveness and these rankings used to define the most cost-effective routes to achieving the various ratings for each of the proposed buildings and scenarios.

[top]Operational carbon results

The influence of the different structural forms studied was found to have only a very small impact on the predicted operational carbon emissions from all five buildings. For the school, office and mixed-use buildings, the impact of alternative structural form (with and without suspended ceilings) on annual regulated carbon emissions was predicted to vary by less than 1%. For the low rise warehouse and supermarket buildings, the variation was slightly greater at around 3%. This variation was due mainly to the different depths of the alternative structural options and the corresponding internal volumes.

Increased storey heights result in greater heat losses and therefore higher heating but lower cooling requirements. The interaction of these impacts was complex and the predicted net effect on the total operational carbon emissions was variable but generally small.

The table gives the building emission rate (BER), the unit capital construction cost, the predicted total operational carbon emissions, normalised to GIFA, for each building and the ratio of annual operational carbon emissions to capital construction cost.

| Building | BERa (kgCO2pa/m2) |

Capital construction cost (£/m2) |

Total operational carbon emissions (kgCO2pa/m2) |

Ratio (tCO2pa/£M) |

|---|---|---|---|---|

| Distribution warehouse | 23.9 | 549 | 29.9 | 54.5 |

| Supermarket | 55.5 | 1,746 | 74.4 | 42.6 |

| Secondary school | 27.3 | 2,335 | 36.8 | 15.8 |

| Office | 31.4 | 1,869 | 44.1 | 23.6 |

| Mixed-use | 42.8 | 1,970 | 63.7 | 32.3 |

aBER = Building Emissions Rate which includes only regulated emissions under Part L of the Building Regulations

[top]Distribution warehouse

A summary of what were found to be the most cost effective routes to the likely future low and zero operational carbon reduction targets for the Base Case distribution warehouse building is provided. It shows the most cost effective combination of energy efficiency and LZC measures to achieve different levels of operation carbon reduction, the capital cost of the package of measures and the 25-year net present value (NPV) saving that these measures yielded relative to the Base Case building performance.

More detailed information and guidance is available in the Target Zero Warehouse building design guide.

[top]Supermarket building

A summary of the most cost effective routes to the likely future low and zero operational carbon reduction targets for the Base Case supermarket building is provided. It shows the most cost effective combination of energy efficiency and LZC measures to achieve different levels of operation carbon reduction, the capital cost of the package of measures and the 25-year net present value (NPV) saving that these measures yield relative to the Base Case building performance.

More detailed information and guidance is available in the Target Zero Supermarket design guide.

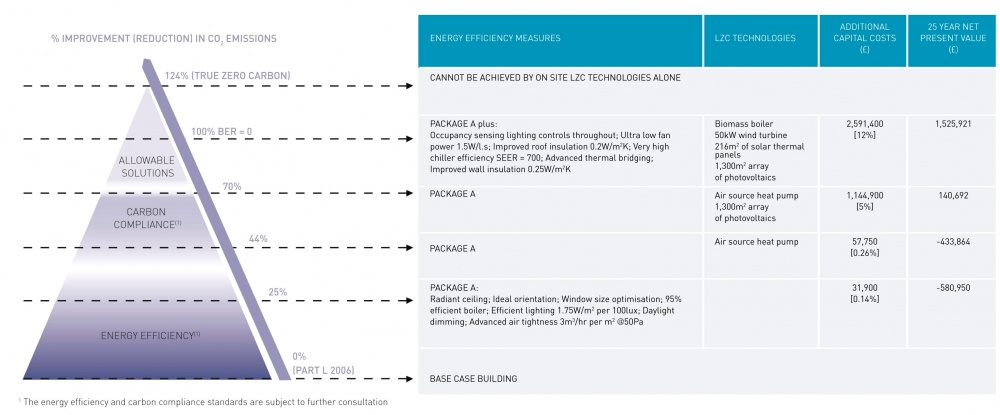

[top]Secondary school building

A summary of the most cost effective routes to the likely future low and zero operational carbon reduction targets for the Base Case secondary school building is provided. It shows the most cost effective combination of energy efficiency and LZC measures to achieve different levels of operation carbon reduction, the capital cost of the package of measures and the 25-year net present value (NPV) saving that these measures yield relative to the Base Case building performance.

More detailed information and guidance is available in the Target Zero Schools design guide.

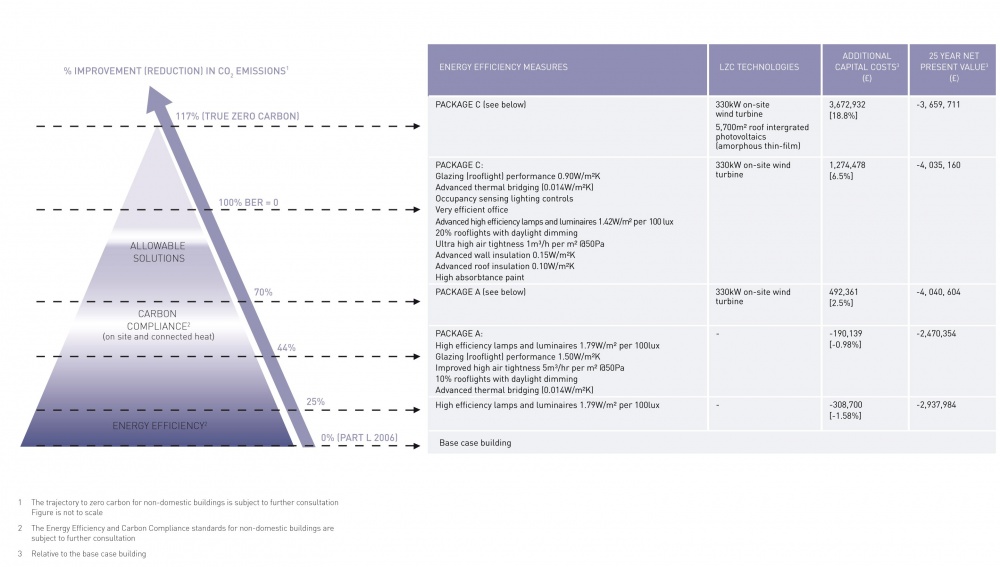

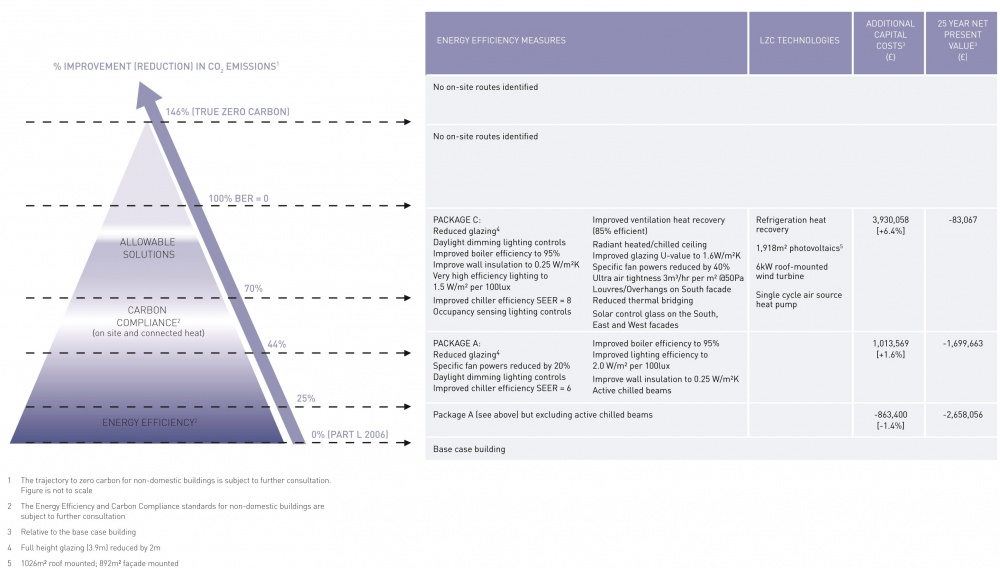

[top]Office building

A summary of the most cost effective routes to the likely future low and zero operational carbon reduction targets for the Base Case office building is provided. It shows the most cost effective combination of energy efficiency and LZC measures to achieve different levels of operation carbon reduction, the capital cost of the package of measures and the 25-year net present value (NPV) saving that these measures yield relative to the Base Case building performance.

More detailed information and guidance is available in the Target Zero Office building design guide.

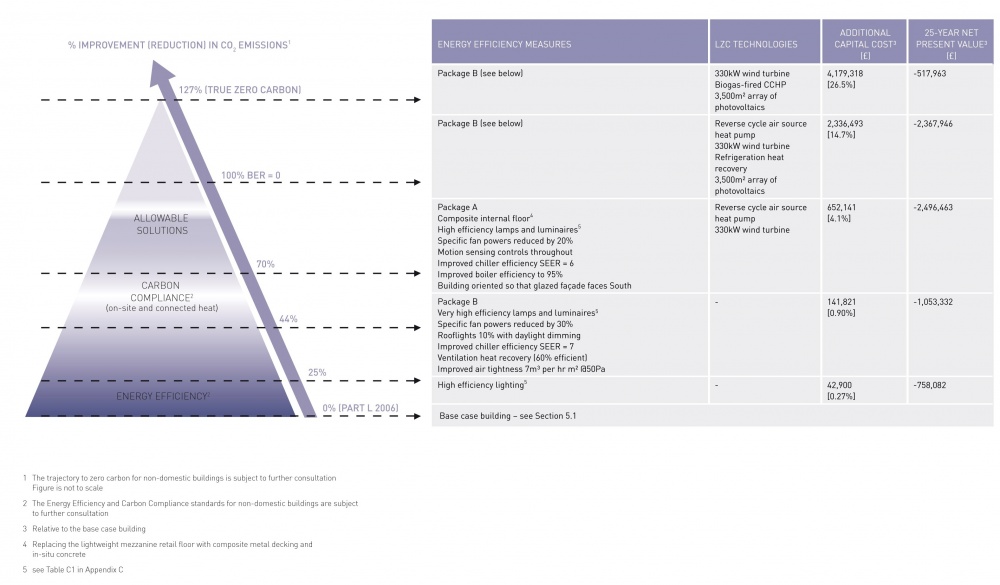

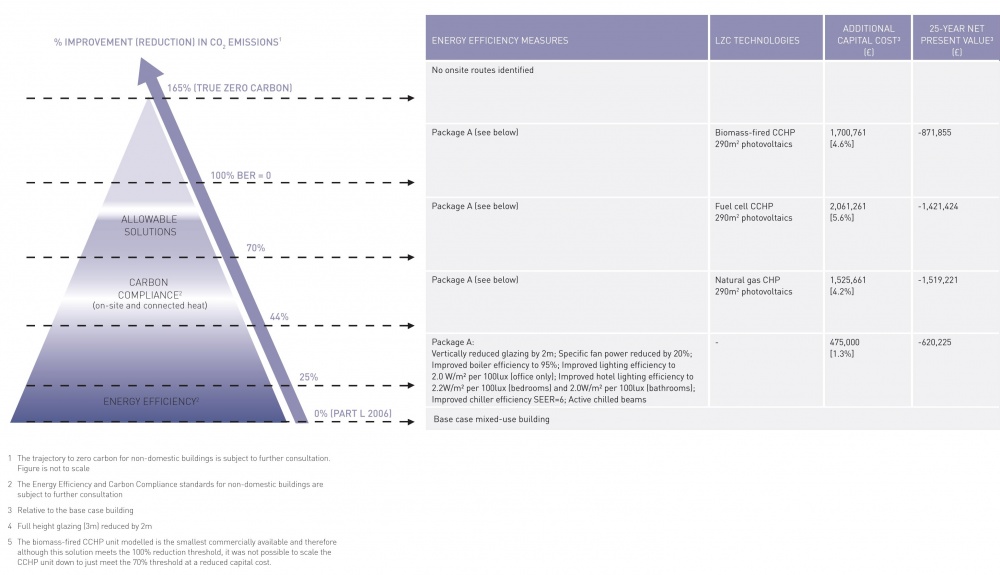

[top]Mixed-use building

A summary of the most cost effective routes to the likely future low and zero operational carbon reduction targets for the Base Case mixed-use building comprising office and hotel accommodation is provided. It shows the most cost effective combination of energy efficiency and LZC measures to achieve different levels of operation carbon reduction, the capital cost of the package of measures and the 25-year net present value (NPV) saving that these measures yield relative to the Base Case building performance.

More detailed information and guidance is available in the Target Zero Mixed-use building design guide.

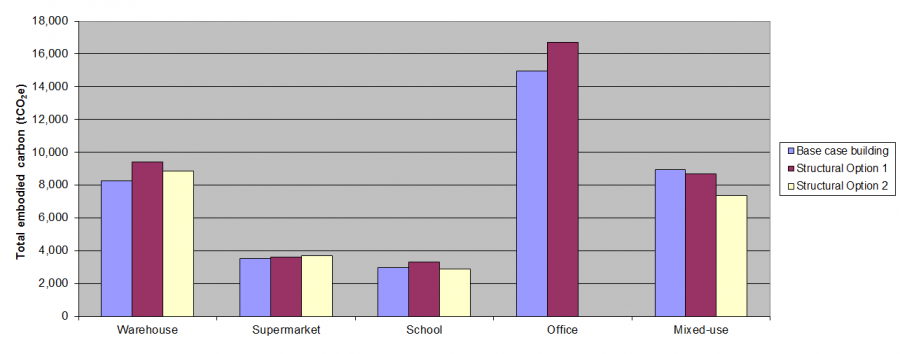

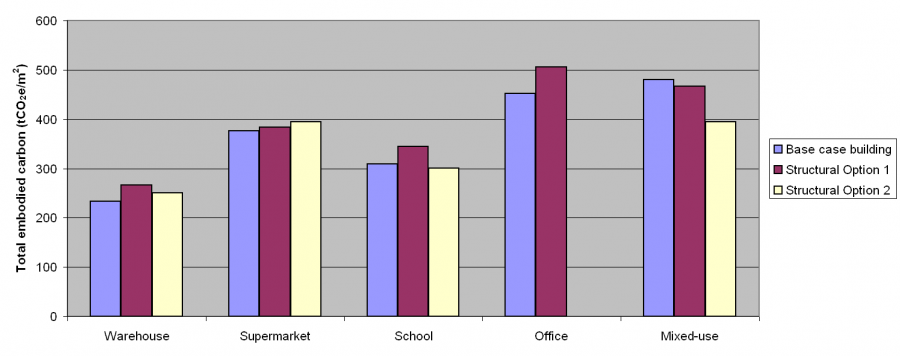

[top]Embodied carbon results

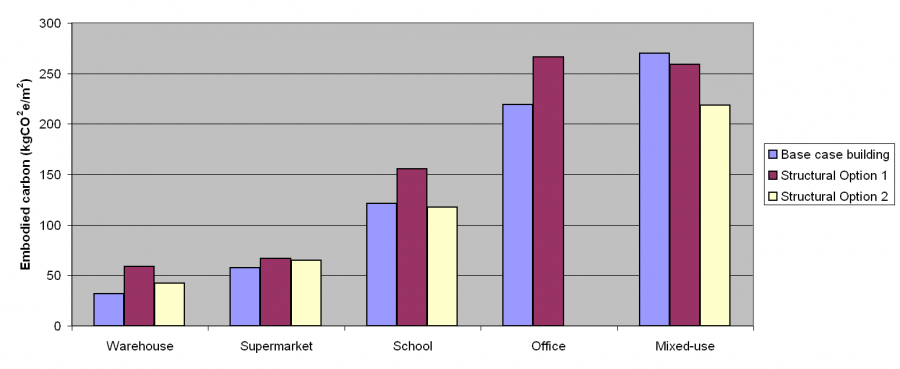

The total embodied carbon emissions for each building and for each alternative structural option considered are shown.

The same set of results are shown again but with the total embodied carbon emissions normalised to gross internal floor area (GIFA). The normalised carbon emissions vary between 234kgCO2e/m2 for the distribution warehouse (Base Case) up to 506kgCO2e/m2 for the high-rise office building (Structural option 2). It is noted that the LETI Climate emergency design guide[8] gives a 2020 best practice target of 600 kgCO2e/m2 GIFA for non-domestic buildings.

The variation in the embodied carbon in the frame and upper floors for each building normalised to the gross internal floor area is shown. The normalised embodied carbon emissions vary between 32CO2e/m2 for the distribution warehouse (Base Case) up to 270kgCO2e/m2 for the mixed-use building (Base Case).

The low-rise buildings (warehouse and supermarket buildings) show similar results as do the high rise buildings assessed (office and mixed-use). The school building (three storeys) lies midway between the two datasets.

The frame and upper floors in the low-rise buildings represent 14% to 22% of the total building embodied carbon. For the high-rise buildings, the frame and upper floors make up 48% to 66% of the total impact.

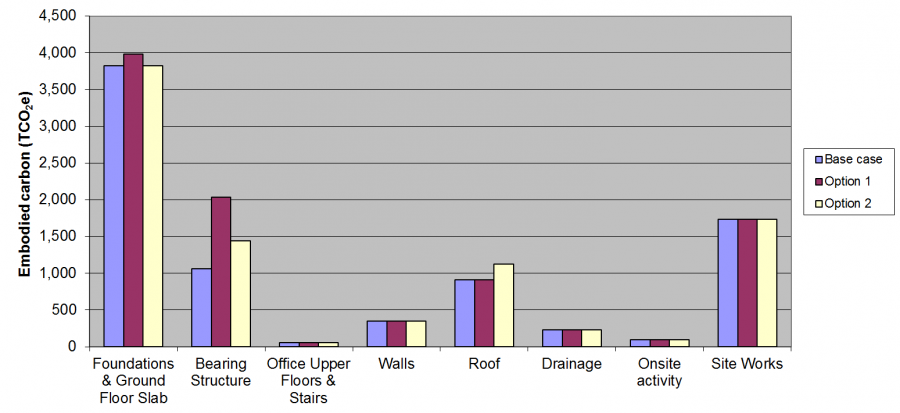

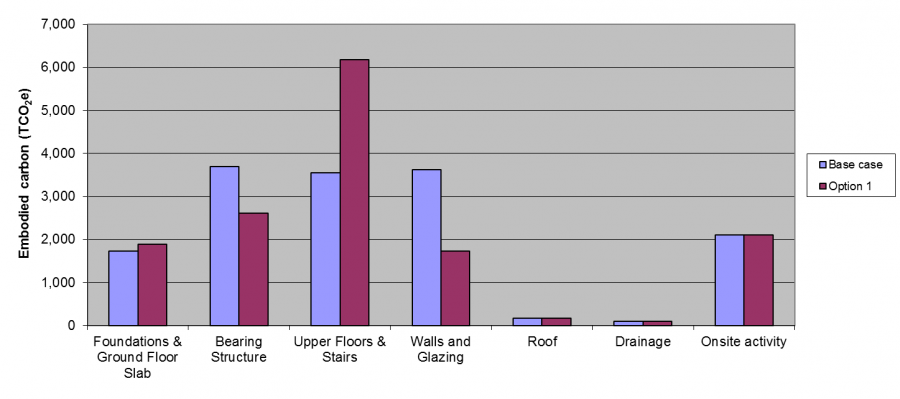

[top]Distribution warehouse - embodied carbon breakdown

The breakdown in total embodied carbon emissions for the distribution warehouse building by major elements is shown. Results are for the Base Case building and the alternative structural forms considered.

The largest contribution in all three structural options comes from concrete, most of which is used in the foundations and floor slab. Even though on a per tonne basis concrete is relatively low in embodied carbon, the volume of concrete used in the building makes its contribution significant. This additional concrete is also significant if other issues such as resource depletion, waste and end-of-life are considered.

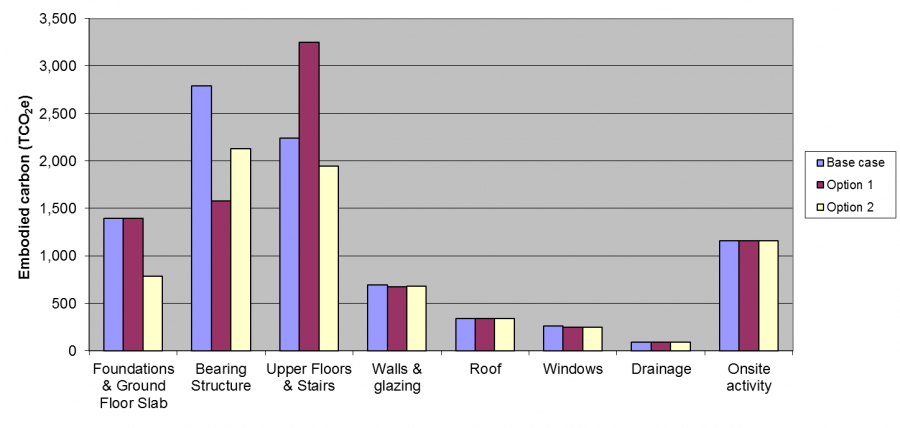

[top]Supermarket building - embodied carbon breakdown

The breakdown in total embodied carbon emissions for the supermarket building by major elements is shown. Results are for the Base Case and the alternative structural forms considered.

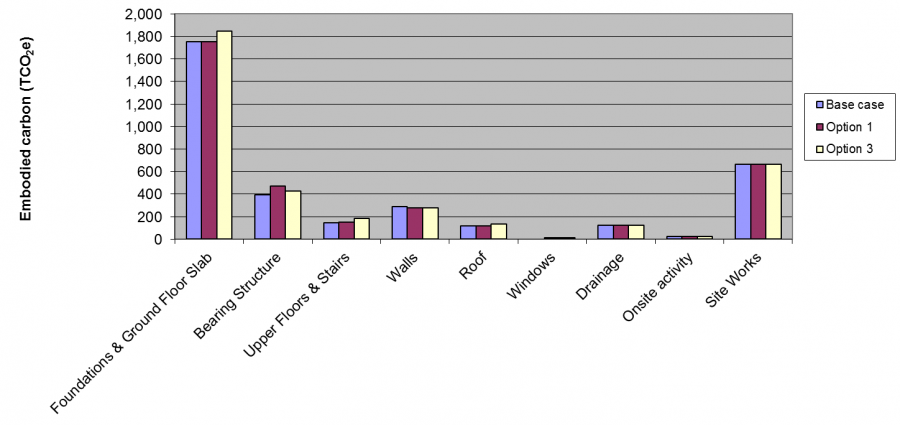

[top]Secondary school building - embodied carbon breakdown

The breakdown in total embodied carbon emissions for the secondary school by major elements is shown. Results are for the Base Case building and the alternative structural forms considered.

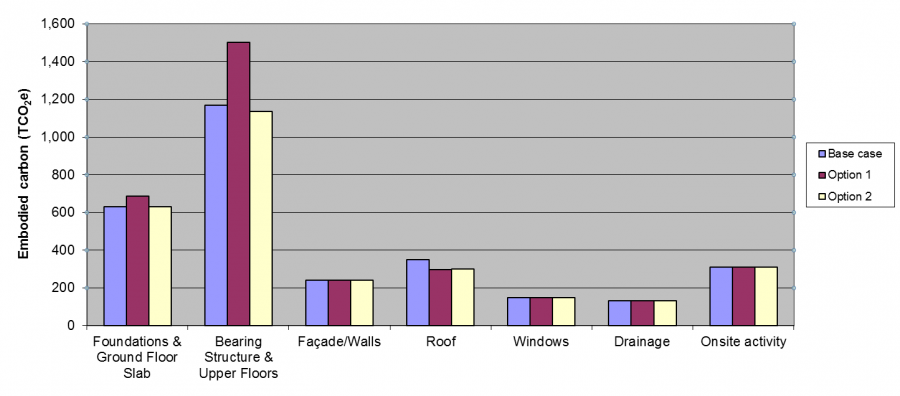

[top]Office building - embodied carbon breakdown

The breakdown in total embodied carbon emissions for the office building by major elements is shown. Results are for the Base Case and the alternative structural forms considered.

[top]Mixed-use building embodied carbon breakdown

The breakdown in total embodied carbon emissions for the mixed-use building by major elements is shown. Results are for the Base Case and the alternative structural forms considered.

[top]BREEAM results

The capital cost increase or ‘uplifts’ for the Base Case buildings to achieve ‘Very Good’, ‘Excellent’ and ‘Outstanding’ BREEAM ratings (2008) are shown. The capital costs are based on the most cost effective route identified for the Base Case and its actual location.

| Building | Capital construction cost (£m) | Capital cost uplift (%) to achieve BREEAM | ||

|---|---|---|---|---|

| Very Good | Excellent | Outstanding | ||

| Distribution warehouse | 19.4 | 0.04 | 0.4 | 4.8 |

| Supermarket | 16.4 | 0.2 | 1.8 | 10.1 |

| Secondary school | 22.5 | 0.2 | 0.7 | 5.8 |

| Office | 61.7 | 0.2 | 0.8 | 9.8 |

| Mixed-use | 36.7 | 0.1 | 1.6 | 5.0 |

The Target Zero design guides provide detailed breakdowns of the most cost effective routes for each building. These are summarised in the schematic diagrams below. For a 'Very Good' rating, designers should consider the credits in the white boxes; for an ‘Excellent’ rating, the credits in both the white and orange boxes need to be considered; for an ‘Outstanding’ rating, all credits need to be considered.

[top]References

- ↑ Zero carbon for new non-domestic buildings; Phase 3 final report. Department for Communities and Local Government, July 2011

- ↑ 2.0 2.1 2.2 BS EN ISO 14040:2006, Environmental management – Life cycle assessment – Principles and framework. BSI

- ↑ 3.0 3.1 3.2 3.3 BS EN ISO 14044:2006, Environmental management – Life cycle assessment – Requirements and guidelines. BSI

- ↑ Department for Transport (2008), Transport Statistics Bulletin – Road Freight Statistics 2007

- ↑ WRAP Net Waste Tool Reference Guide v 1.0, 2008

- ↑ World Steel Association Life Cycle Inventory Study for Steel Products: Methodology report, World Steel Association, July 2011

- ↑ CML 2001 Global Warming Potential (GWP 100 years) Handbook on impact categories. Institute of Environmental Sciences, Leiden University. December 2007.

- ↑ LETI Climate Emergency Design Guide, How new buildings can meet UK climate change targets, London Energy Transformation Initiative (LETI), January 2020.

[top]Further reading

[top]Resources

Target Zero design guides:

- Guidance on the design and construction of sustainable, low carbon office buildings

- Guidance on the design and construction of sustainable, low carbon warehouse buildings

- Guidance on the design and construction of sustainable, low carbon supermarket buildings

- Guidance on the design and construction of sustainable, low carbon mixed-use buildings

- Guidance on the design and construction of sustainable, low carbon school buildings