Life cycle assessment and embodied carbon

As the operational energy efficiency of buildings is improved, the relative importance of the embodied carbon impacts of buildings is increasing. As a consequence, greater attention is being placed on how the embodied carbon (or carbon footprint) of buildings is measured. Doing this accurately can be a challenge!

Embodied carbon assessment is a subset of a broader discipline called Life Cycle Assessment (LCA) which covers a range of different environmental impacts. As such, many of the principles are equally applicable to both assessment methods.

This article:

- Introduces LCA and embodied carbon

- Describes some key aspects that designers should be aware of

- Gives sources of construction LCA data

- Provides information on whole life embodied carbon data for steel and other common framing materials.

- Presents the results of some recent comparative embodied carbon studies.

[top]What is Life Cycle Assessment?

First developed in the 1960s, Life Cycle Assessment (LCA) is the most widely used and highly regarded tool for quantifying the environmental impacts of products and services. Despite being conceptually quite straightforward, LCA can be very complex with many important, often material-specific, assumptions than can significantly influence the outcome. LCA is the tool that is used to develop Environmental Product Declarations (EPD) which are a standardised set of environmental information based on a common set of rules called Product Category Rules (PCRs). EPD are increasingly being used by construction product manufacturers in the UK and the EU to provide robust, quantified environmental data for their products.

LCA involves the collection and evaluation of quantitative data on the inputs and outputs of material, energy and waste flows associated with a product over its entire life cycle so that its whole-life environmental impacts can be determined.

An LCA essentially comprises three steps:

- Compiling an inventory of relevant energy and material inputs and environmental releases (outputs) associated with a defined system. Releases can be solid wastes or emissions to air or water

- Evaluating the potential impacts associated with these inputs and releases, e.g. the global warming impact from CO2 emissions

- Interpreting the results to help make informed decisions.

If the LCA study is to make comparative results public then a critical review of the study to ISO 14044[1] must be provided.

An important first step in any LCA is to clearly define the goal and scope of the study. The goal and scope of the study should define key details of the study including:

- The functional unit of the product or system to be assessed, e.g. a tonne of structural steel, 1m2 of external wall or a whole building, etc

- The system boundaries, i.e. what is included/excluded from the scope of the assessment

- Any specific assumptions and limitations of the study

- The allocation methods used to partition the environmental load of a process when several products or functions share the same process, e.g. blast furnace slag is a valuable by-product of steelmaking from iron ore and therefore should carry a proportion of the environmental impact from steelmaking to the product in which it is used. Allocation is used to ‘allocate’ a proportion of the environmental impact from steelmaking to the blast furnace slag

- The environmental impact categories chosen, e.g. if only the climate change impact is included within the scope of the LCA, then the assessment is in fact an embodied carbon assessment.

LCA methodology is flexible in terms of the goal and hence scope of assessment, however a robust LCA of a construction product (or a building) should include the impacts of:

- Extraction of the relevant raw materials, e.g. quarrying, mining

- Refinement and conversion to process materials, e.g. steelmaking or cement production

- Manufacturing and packaging processes, e.g. steelwork fabrication or making precast concrete products

- Transportation and distribution between each stage

- Waste at each stage

- On-site construction impacts, e.g. water and energy use, temporary works, shuttering, worker commuting, etc

- Operation during the lifetime of the building including maintenance, refurbishment, replacement, etc.

- At the end of its useful life, demolition, final transportation, waste treatment and disposal.

Any recycling or recovery operations built into the life cycle should lead to a proportionate reduction in the adverse environmental impact and should be accounted for.

[top]LCA impact categories

The impact of the inventory of flows or outputs from a system is assessed and interpreted by linking them to environmental impact categories through a process known as characterisation. The environmental impact categories generally considered in an LCA study are shown; the most common categories are shown in bold.

| Climate change | Ecotoxicity to land |

| Water extraction | Waste disposal |

| Mineral resource extraction | Fossil fuel depletion |

| Stratospheric ozone depletion | Eutrophocation |

| Human toxicity | Photochemical ozone creation |

| Ecotoxicity to freshwater | Acidification |

| Nuclear waste (high level) |

Environmental impacts in one category can be caused by many different emissions and therefore characterisation factors are used to combine the impact of different substances. A good example of this, which is also relevant to embodied carbon assessments, is the impact category of climate change.

Climate change is caused by a number of different greenhouse gases each which have a greater or lesser impact on the climate over time. In LCA therefore (and in robust embodied carbon studies) climate change characterisation factors (or global warming potentials (GWP) - see table below) are used to combine the global warming potential of different greenhouse gases to derive a single metric, in this case CO2e or carbon dioxide equivalents. Similar characterisation processes are undertaken for other LCA impact categories.

| Greenhouse gas | GWP – 100 year timeframe (kgCO2e) |

|---|---|

| Carbon dioxide (CO2) | 1 |

| Methane (CH4) | 25 |

| Nitrous oxide (N2O) | 298 |

| Sulphur hexafluoride (SF6) | 22800 |

| Perfluorobutane (C4F10) | 8860 |

| HFC 134a (tetrafluoroethane) | 1430 |

Having established quantitative measures for each of the impact categories within the scope of the LCA, a further step undertaken in some LCA methodologies is to weight the different impact categories to produce a single value of environmental impact. Although this approach is not endorsed in LCA standards, it can be used to produce a single metric scoring system that is easy to understand for users.

An example of an LCA methodology which uses this approach is BRE’s Environmental Profiles, (for which a methodology guide is available[2]) when it is used to determine the Green Guide to Specification[3] ratings. To produce a single value of environmental impact, two steps are employed:

- Normalisation – the 13 environmental impact category scores assessed by BRE are normalised to the annual impact of an average European citizen

- Weighting – the normalised category scores are then combined using weightings of environmental importance, derived from a panel of European experts.

The resulting single value of environmental impact has the units of Ecopoints where 100 Ecopoints is equivalent to the annual impact of an average European citizen.

[top]LCA codes and standards

The principle standards governing the use of LCA are the ISO 14040 series of standards. These provide guidance on:

Previously, three additional standards existed:

- Goal and scope definition ISO 14041[5]

- Life cycle impact assessment ISO 14042[6]

- Life cycle interpretation ISO 14043[7]

These have been withdrawn and are now covered by revised versions of ISO 14040[4] and 14044[1].

These are generic standards applicable to all types of LCA study, i.e. not just construction or building related studies.

In the context of building and construction LCA, the standards recently developed by CEN TC 350 will be very influential in defining how the environmental impacts of construction products and buildings are assessed and will ensure that they are undertaken on a robust and consistent basis throughout the EU.

These standards have been developed in response to the plethora of different sustainability schemes being developed in Europe, which prompted the European Commission to issue a mandate to CEN to develop horizontal standardised methods for the assessment of the integrated environmental performance of buildings. Subsequently the remit was broadened to include social and economic dimensions.

European Standards Technical Committee CEN/TC350 and its various working groups, began work in 2005 and a suite of standards have been developed. These include:

The importance of European Standards is that EU Member States, must use European Standards where they exist when regulating and, if they exist, National Standards must be withdrawn if they are in conflict with European Standards. So, for example, if the UK decided to regulate on measuring the sustainability of buildings and construction products then the UK will have to use the CEN/TC350 standards.

European Standards remain voluntary but their transposition into national standards and the withdrawal of diverging national standards is mandatory according to the internal rules of the European Standards Organisations.

In the UK, the leading environmental assessment methodology for construction materials and products is BRE’s Environmental Profiles. BRE’s methodology is founded on LCA principles and is used to derive the Green Guide to Specification[3] ratings that are used in BREEAM to asses the embodied environmental impact of construction products.

In light of the recently published CEN TC 350 standards, BRE has indicated that it will:

- Offer EPD to both BRE’s Environmental Profiles methodology[2] and BS EN 15804[10]

- Continue to offer Green Guide to Specification[3] ratings using the BRE Environmental Profiles methodology[2].

[top]The Construction Products Regulation (CPR)

The Construction Products Directive[13] (1989) was one of the first Directives from the EU Commission to create a common framework for the regulation of buildings and construction products. It was replaced by the Construction Products Regulation[14] (CPR) in 2011, which is legally binding throughout the EU. The CPR includes requirements for:

- Sustainable use of natural resources – under Basic Construction Works requirement 7

- Reduced environmental impact from toxic gases, VOCs, greenhouse gases or dangerous particles, etc. over the life cycle – under Basic Construction Works requirement 3.

It is likely that the use of Environmental Product Declarations (EPD) will be the principal means of assessing and reporting the environmental impacts of construction products under the CPR.

If an EU Member State wishes to regulate in these areas of sustainability it must use European standards where they exist when regulating and must withdraw national standards. This means that in the case of the CPR, a Member State must use the CEN/TC 350 suite of standards.

[top]Environmental product declarations

Environmental Product Declarations (EPD), are used to provide environmental information from LCA studies in a common format, based on common rules, known as Product Category Rules (PCR). The construction industry has widely adopted EPD as the means of reporting and communicating environmental information. [Note: the plural of EPD is EPD].

Within Europe, PCR for construction products have been developed in the UK, France, the Netherlands, Scandinavia and Germany and EPD are published by Scheme Operators. For example, in the UK, EPD (Environmental Profiles) are produced by BRE Global and BBA.

ISO 14025[15] sets out standards for developing EPD. This standard also draws on the key LCA standards ISO 14040[4] and ISO 14044[1].

To be comparable, EPD must have been developed using the same PCR, to ensure scope, methodology, data quality and indicators are the same. EPD can only be compared when the same PCR have been used and all the relevant life cycle stages have been included. This is a frequent limitation or failing of many comparative LCA studies.

At present, a manufacturer selling the same product in several different European markets cannot use a single EPD programme and may have to produce a separate EPD for each region, which can be at considerable expense. This is why European standards under CEN TC 350 have been developed.

[top]What is embodied carbon?

The term ‘embodied carbon’ refers to the lifecycle greenhouse gas emissions (expressed as carbon dioxide equivalents – CO2e) that occur during the manufacture and transport of construction materials and components, as well as the construction process itself and end-of-life aspects of the building. In recent years, the term ‘embodied carbon’ of construction materials and products has become synonymous with the term ‘carbon footprint’. An embodied carbon or carbon footprint assessment is a subset of most LCA studies.

The embodied carbon and the in-use carbon emissions from the operation of the building (operational carbon) together make up the complete lifecycle carbon footprint of the building.

The scale of the potential threat of global climate change has focused attention on carbon emissions and therefore most construction related environmental impact studies focus on this impact category. While carbon emissions are clearly a priority, more thorough environmental assessments should consider a wider range of impact categories; as is routinely done in LCA studies. As regulations are tightened to reduce the operational carbon emissions from new buildings, the relative importance of embodied carbon impacts is increasing.

An embodied carbon footprint tool for buildings is available.

[top]Embodied carbon codes and standards

As a subset of LCA, embodied carbon assessments (or carbon footprinting) is subject to many of the same standards.

However, methodologies and protocols have begun to emerge on how to measure a carbon footprint in a standardised way; some of which relate to a company or organisational footprint, others to installations and others to a product. These include:

- The Greenhouse Gas Protocol[16] - provides standards and guidance for companies and other organizations preparing a GHG emissions inventory

- PAS 2050[17] – specifies requirements for the assessment of the life cycle GHG emissions of goods and services based on key life cycle assessment techniques and principles

- ISO 14064-1[18] which specifies principles and requirements at the organization level for quantification and reporting of greenhouse gas (GHG) emissions and removals

- ISO 14064-2[19] which specifies principles and requirements and provides guidance at the project level for quantification, monitoring and reporting of activities intended to cause greenhouse gas (GHG) emission reductions or removal enhancements

- ISO 14064-3[20] which specifies principles and requirements and provides guidance for those conducting or managing the validation and/or verification of greenhouse gas (GHG) assertions.

There are also many publications giving guidance on how to assess the embodied carbon of buildings and construction products – see Further reading.

[top]LCA scope and system boundaries

System boundaries determine which processes are included (or excluded) in an LCA or embodied carbon study or an EPD. Different scopes and systems boundaries that can be considered, and which should be clearly defined, include:

- Geographical area, e.g. UK, EU, World, etc

- Time horizon, i.e. when the data were collected

- Boundaries between the specific system studied and related technical systems, for example, the production of capital goods used to manufacture a product

- Boundaries between the technological system and nature, i.e. which life cycle stages are included within the system boundary. Common examples include ‘cradle-to-gate’ and ‘cradle-to-cradle’ system boundaries.

It is important when undertaking LCA or embodied carbon assessments that the systems boundaries are clearly defined and, when comparative assessments are undertaken, that the data used are consistent in terms of the scope and boundaries defined above. This is a common failing of many comparative studies.

[top]Cradle-to-gate vs cradle-to-cradle

An important scoping decision in LCA and embodied carbon studies is which parts of the product life cycle are included.

Studies in which the impacts are assessed only to the point where the product leaves the factory gate are called ‘cradle-to-gate’ studies. Those which include all life cycle phases up to the point where the building is demolished and materials disposed of as waste or recovered and recycled, are called ‘cradle-to-cradle’ studies.

It is generally recognised that robust studies should include cradle-to-cradle impacts. This is posible using both BS EN 15804[10] and ISO 14044[1]

[top]BS EN 15804 Life cycle stages

BS EN 15804[10] provides a core set of Product Category Rules (PCRs) for the Europe-wide generation of EPD for construction products. PCRs define the methods for the collection of data, the calculation of environmental impact and how the information should be presented.

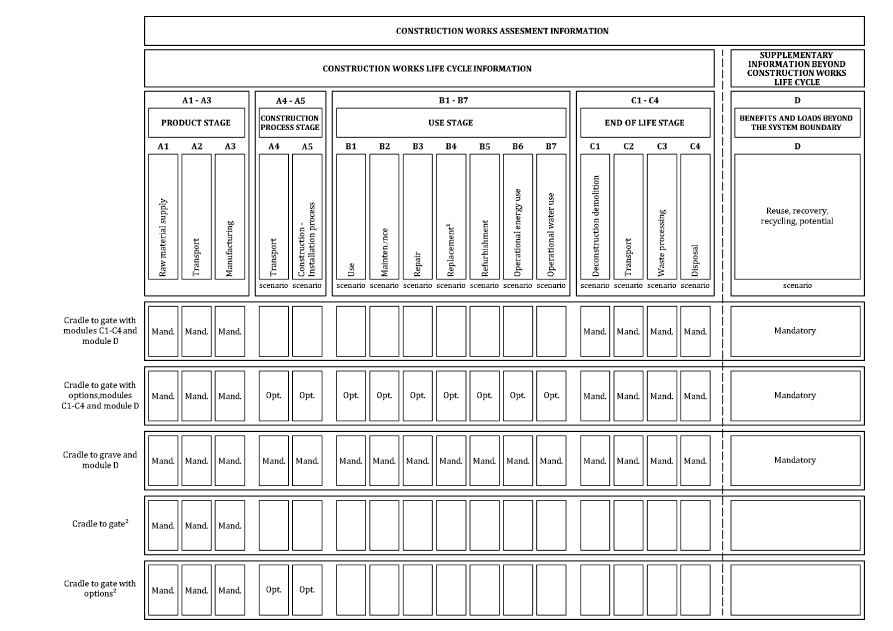

BS EN 15804[10] defines the various building life cycle stages that can be included within LCAs and EPD and these are shown. Different life cycle stages are either mandatory or optional for different scope of EPD. It is noted that only Modules A1 to A3 are mandatory under BS EN 15804[10], all other phases are optional.

Permission to reproduce extracts from British Standards is granted by the British Standards Institution (BSI). No other use of this material is permitted. British Standards can be obtained in PDF or hard copy formats from the BSI online shop: or by contacting BSI Customer Services for hard copies only: Tel: +44 (0)20 8996 9001, Email: cservices@bsigroup.com

There is also an additional module (Module D) which can be included in the scope of the assessment. Module D allows supplementary information beyond the building life cycle to be considered. For construction products, this means the benefits and burdens of disposal after demolition can be taken into account. The use of Module D is consistent with a cradle-to-cradle approach.

For the metals industries, Module D provides the opportunity to take into account the fact that their materials are not limited to one life cycle, and can be recycled almost indefinitely without loss of properties, and also that this has the positive effect of displacing production from primary materials.

The net benefit of this indefinite recycling, taking care not to include the impacts of recycled material already used in production, can then be credited against the impacts of the original production from the primary materials.

In summary, the presence of Module D in BS EN 15804[10] allows credits to be taken now for the eventual reuse or recycling of material in the future as long as the reuse and recycling scenario is based on current practices (and supported by robust data).

(Module D can be used in many scenarios. It is not required only in order to quantify material recovery benefits. It can also, for example, be used to quantify the benefits of surplus energy that might be generated by a building. For example, a building that generates renewable PV electricity and exports surplus energy to the grid, can report the carbon emission reduction benefits of generating that additional energy in Module D, since the building also has to report the embodied carbon of the PV installation in Module A. The use of Module D may be the only way to report these benefits and this gives validity to its use).

It is noteworthy that BS EN 15978[11], which has been produced by CEN TC 350 with the objective of aggregating the impacts from the EPD developed using EN 15804[10], states that If relevant information is provided at the product level on Module D, this information should be reported. In other words, if the information required to use Module D is available (in the case of construction materials this is the recycling/reuse/landfill etc rates at end of life) it should be used.

[top]Accounting for end-of-life impacts

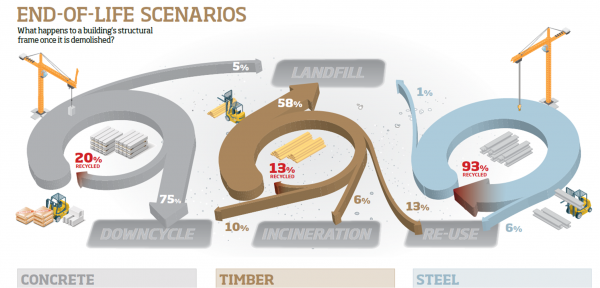

Assumptions made about the disposal of materials from buildings after they are demolished can have a significant effect on their whole lifecycle environmental impacts. For example, an LCA of bio-based products which includes that fact that many of these end up in landfill where they decompose and emit methane can have a significant adverse impact on the result. By contrast, an LCA of steel construction products which takes into account that fact that 96% are reused or recycled can have a very positive impact.

Studies that exclude end-of-life impacts, such as cradle-to-gate studies, make no differentiation between these two very different scenarios.

Recycling material at end of life obviously provides a benefit, as does using recycled material in the first place. Different approaches to this benefit are used in LCA and embodied carbon studies.

It is generally recognised that a robust and thorough LCA study should include end-of-life impacts and therefore cradle-to-cradle studies are preferred over cradle-to-gate studies. There are several different methods for accounting for recycling within cradle-to-cradle studies studies. Three of the most common methods are:

- Recycled content approach in which the full benefits of material recycling are allocated to the input side of a product system. This leaves no benefit for end of life recyclability.

- Closed loop recycling, in which the creation of recyclable material is allocated the full benefit of recycling at end of life (called recyclability). This leaves no benefit for incoming recycled materials, which are effectively neglected.

- Methods in which the impacts and benefits of recycling are shared (or allocated), by some means, between the input and output sides of the product system.

In LCA studies, the type of recycling is significant and can be described as either open or closed loop which reflects the changes in inherent properties of the materials that are recycled.

- Open loop recycling involves the conversion of material from one product life cycle into another product life cycle. This usually involves a change in the inherent properties of the material itself (often a degradation in quality). For example, recycling plastic bottles into plastic drainage pipes. Often this is called downcycling or reprocessing.

- Closed loop recycling describes the recycling of a product into an identical product, for example recycling a steel beam into another steel beam.

Closed-loop recycling poses relatively small methodological problems in LCA, whereas open-loop recycling can incur major allocation problems. Basically, open-loop recycling creates a new, larger system which should be treated as one system. Since this is often not possible, or very difficult and complex, allocation rules have to be applied in order to treat one of the subsystems separately.

In LCA terms, steel products are described as flowing in ‘open loop’ recycling systems, e.g. a steel beam can be recycled into another steel beam but is just as likely to be recycled into a car or a tin can, etc. However, since there is no change in the inherent material properties, recycling steel can be considered as ‘closed loop’ and allocation avoided by expanding the system to include both primary and secondary production. This ‘closed-loop’ approach forms the basis of the recycling methodology adopted by the metals industries generally, including the World Steel Association[21].

[top]Accounting for the recycling of steel

Accounting for the benefits of recycling in LCA and embodied carbon studies is important for highly recycled materials like steel. The impact of using the Module D approach in BS EN 15804[10] and the closed loop recycling approach of ISO 14044[1] to calculating the benefits and burdens of disposal after demolition are very similar. Illustrations of closed loop recycling calculations for steel slab production are available[22].

[top]Construction LCA and embodied carbon data sources

There are a number of sources of LCA and embodied carbon data for construction products. These include:

[top]The Building Research Establishment (BRE)

The BRE provides several types of LCA data and tools including:

- EPD (called BRE Environmental Profiles) of construction products and materials. Both generic and proprietary EPD have been produced but only a few are currently publicly available. The EPD data generated by BRE are used in other BRE resources and tools including the Green Guide to Specification[3], Envest2 and IMPACT.

- Green Guide to Specification[3] provides environmental ratings (summary and individual category rating) and embodied carbon data for over 1,200 common construction specifications used in various building types.

- IMPACT developed in partnership with IES, IMPACT uses CAD techniques to allow users to quantify the embodied environmental and cost implications on a whole-building basis. LCA and life cycle costing (LCC) data are provided by BRE and are coupled with other operational impact modules provided by IES.

[top]Inventory of Carbon and Energy (ICE)

Developed by the University of Bath, the ICE[23] is a database of embodied carbon and energy values for common construction materials. As such it has been widely used in many assessment tools developed by others and in many construction embodied carbon studies.

It is important to note that the ICE is not the product of a rigorous LCA study but rather a review of published information from other sources. As such, the values in the database are variable in terms of scope, age and quality and consequently data from the ICE should be used with care in comparative embodied carbon studies.

The ICE database scope is ‘cradle-to-gate’ only.

[top]Specialist LCA software providers

There are a number of specialist providers of LCA services that develop and sell LCA construction datasets. These include:

[top]Manufacturers and trade associations

Many large manufacturers of construction products and trade associations have either commissioned or developed their own LCA and embodied carbon datasets or EPD. In the UK these have generally been Environmental Profiles developed by BRE although other LCA consultants are increasingly used to develop EPD.

In the case of steel data, worldsteel is the source of comprehensive and up-to-date data. Many commercial LCA databases use the worldsteel steel data.

[top]Steel LCA and embodied carbon data

In 1996, worldsteel launched its innovative worldwide life cycle inventory (LCI) study for steel products. This was the first time that such an international study of a specific material had been carried out. The study is regularly repeated and updated and is in accordance with the BS EN ISO 14040[4] series of environmental standards. The closed-loop recycling method from BS EN ISO 14044[1] is used to account for the benefits of steel recycling. .

The worldsteel LCA data have been used in many LCAs; around 200 requests for data are made each year. LCAs are used for benchmarking performance, improving products, addressing legislative requirements and assessing competition between materials. Requests for worldsteel LCA data can be made by filling in the online questionnaire to describe how the data are to be used. The request is then discussed with the worldsteel LCA Manager. The latest dataset was published by worldsteel in 2017.

In addition, in 2013, bauforumstahl, the independent steel promotional organisation in Germany published an EPD based on data collected from the biggest hot rolled steel sections and plates manufacturers in Europe. This 'European EPD'[24] includes the most up to date embodied carbon data currently available for these products (that includes input from UK steel plants) and is based on the Module D approach from BS EN 15804[10].

This has fed into a comprehensive new database of information on end of life LCA and embodied carbon data for construction materials. The following information is extracted from that.

| Sections and plate | Hot finished/formed Tubes | Steel deck | |

|---|---|---|---|

| CO2e (tonnes/tonne) |

0.84 | 1.17 | 1.13 |

Note that these embodied carbon values are aggregated values, i.e. the aggregate of Modules A, C and D.

[top]End of life LCA and embodied carbon data for construction materials

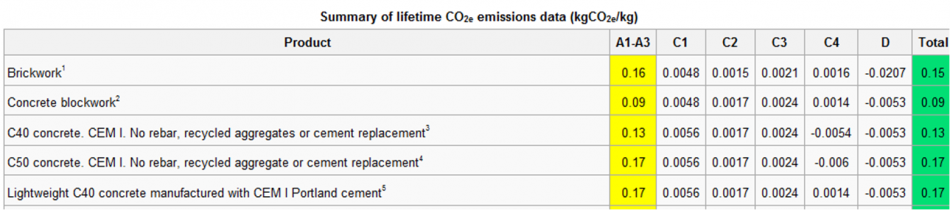

One of the reasons commonly given for choosing a cradle-to-gate rather than a cradle-to-cradle scope in LCA and carbon footprinting studies in construction is the lack of robust data on what happens to materials during and after demolition. This is the Module C and D information as defined in BS EN 15804[10]. PE International (now thinkstep) have examined these impacts for a range of materials commonly used in building framing systems and have derived Module C and D data for steel, concrete and brick/block products.

This data has been added to existing Module A1 to A3 data to derive a summary of whole life embodied CO2e emissions data.

[top]Embodied carbon comparisons

EPD provide environmental data at the component or material level but it is only when these data are aggregated at the building level that sensible comparisons can be made. The reasons for this are principally two-fold:

- EPD are generally produced on a per unit weight basis and therefore take no account of the efficiency of the material or product, for example the weight of structural steel required to support a building is substantially less than the weight of structural concrete required for the equivalent building

- Whole building assessments take account of consequential impacts, for example, if a lighter superstructure is used, then fewer foundations may be required for the building.

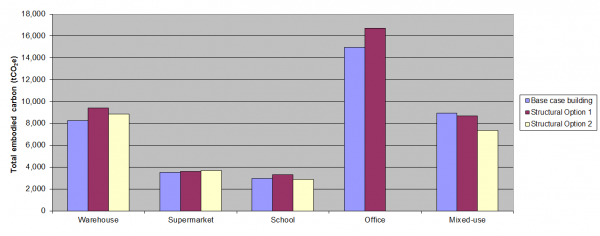

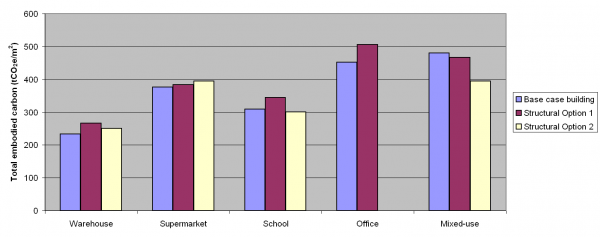

The graph shows the variation in embodied carbon in five different, recently constructed non-domestic buildings – see Target Zero. It shows the total embodied carbon in five buildings each of which has different structural forms. For each building, the base case building (i.e. the building as constructed) has a steel superstructure; the alternative structural options for each building type are defined here. Further details of the embodied carbon assessment methodology are provided here. It should be noted that the embodied carbon emission factors for the principal structural materials used in Target Zero are different to those to be found elsewhere on this site. That is because data changes over time as newer and better information becomes available.

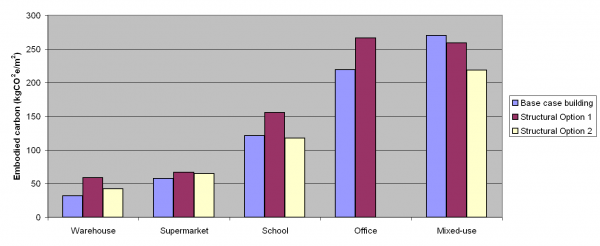

The graph below shows the same results but with the total embodied carbon emissions normalised to the gross internal floor area (GIFA) of each building. The normalised carbon emissions vary between 234 kgCO2e/m2 for the distribution warehouse (Base Case) up to 506 kgCO2e/m2 for the high-rise office building (Structural option 2).

The variation in the embodied carbon in the frame and upper floors for each building normalised to the gross internal floor area is also shown. The normalised carbon emissions vary between 32kgCO2e/m2 for the distribution warehouse (Base case building) up to 270kgCO2e/m2 for the mixed-use building (Base case).

The low rise buildings (warehouse and supermarket) show similar results as do the high rise buildings assessed (office and mixed-use). The school building (three storeys) lies midway between the two datasets. The frame and upper floors in the low-rise buildings represent 14% to 22% of the total building embodied carbon. For the high-rise buildings, the frame and upper floors make up 48% to 66% of the total impact.

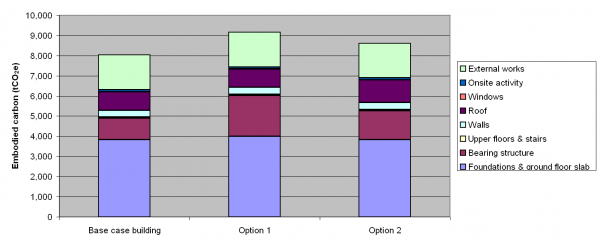

The breakdown of embodied carbon (by element) for a large distribution warehouse is shown here.

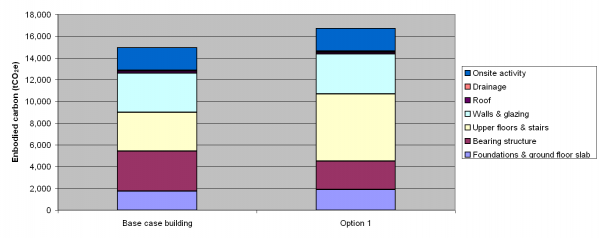

As is the breakdown of embodied carbon (by element) for a large city centre office building.

Detailed breakdowns of the embodied carbon by building element for all five buildings, are presented in the Target Zero design guides.

[top]References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 BS EN ISO 14044:2006+A1:2018. Environmental management – Life cycle assessment – Requirements and guidelines. BSI

- ↑ 2.0 2.1 2.2 Methodology for environmental profiles of construction products: product category rules for type III environmental product declaration of construction products. BRE, August 2007

- ↑ 3.0 3.1 3.2 3.3 3.4 The Green Guide to Specification, 4th ed., BRE and Oxford Brookes University, 2009

- ↑ 4.0 4.1 4.2 4.3 BS EN ISO 14040:2006. Environmental management – Life cycle assessment – Principles and framework. BSI

- ↑ BS EN ISO 14041:1998. Environmental management - Life cycle assessment - Goal and scope definition and inventory analysis. BSI

- ↑ BS EN ISO 14042: 2000. Environmental management - Life cycle assessment - Life cycle impact assessment. BSI

- ↑ BS EN ISO 14043:2000. Environmental management - Life cycle assessment - Life cycle interpretation. BSI

- ↑ BS EN 15643-1:2011 - Sustainability of construction works - Sustainability assessment of buildings - Part 1: General framework. BSI

- ↑ BS EN 15643-2:2011 - Sustainability of construction works - Assessment of buildings - Part 2: Framework for the assessment of environmental performance. BSI

- ↑ 10.00 10.01 10.02 10.03 10.04 10.05 10.06 10.07 10.08 10.09 10.10 10.11 BS EN 15804:2012+A2:2019 - Sustainability of construction works - Environmental product declarations - Core rules for the product category of construction products. BSI

- ↑ 11.0 11.1 BS EN 15978:2011 - Sustainability of construction works - Assessment of environmental performance of buildings - Calculation method. BSI

- ↑ BS EN 16309:2014 - Sustainability of construction works - Assessment of social performance of buildings - Calculation method. BSI

- ↑ Council Directive 89/106/EEC of 21 December 1988 on the approximation of laws, regulations and administrative provisions of the member states relating to construction products.

- ↑ Construction Products Regulation - EU Regulation No 305/2011: Laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC

- ↑ BS EN ISO 14025:2013+A1:2016. Environmental labels and declarations - Type III environmental declarations - Principles and procedures. BSI

- ↑ The Greenhouse Gas Protocol – A corporate accounting and reporting standard – published by the World Business Council for Sustainable Development and the World Resources Institute

- ↑ PAS 2050:2011 Specification for the assessment of the life cycle greenhouse gas emissions of goods and services. BSI

- ↑ BS EN ISO 14064-1:2012. Greenhouse gases - Part 1: Specification with guidance at the organization level for quantification and reporting of greenhouse gas emissions and removals. BSI

- ↑ BS EN ISO 14064-2:2012. Greenhouse gases - Part 2: Specification with guidance at the project level for quantification, monitoring and reporting of greenhouse gas emission reductions or removal enhancements. BSI

- ↑ BS EN ISO 14064-3:2012. Greenhouse gases - Part 3: Specification with guidance for the validation and verification of greenhouse gas assertions. BSI

- ↑ World Steel Association Life Cycle Inventory Study for Steel Products: Methodology report, World Steel Association, July 2011

- ↑ System boundaries in life cycle assessment. Dowling, John. Nordic Steel Conference, Oslo, September 2012

- ↑ Embodied carbon: The inventory of carbon and energy (ICE). BSRIA BG 10/2011, 2011.

- ↑ Environmental Product Declaration. Structural Steel: Sections and Plates, Bauforumstahl, 2013

[top]Further reading

- A guide to understanding the embodied impacts of construction products. Construction Products Association

- A short guide to embodied carbon in building structures. The Institution of Structural Engineers

- Allwood, J. and Cullen, J. M.: Sustainable materials with both eyes open, UIT Cambridge Ltd, 2012

- A comparative embodied carbon assessment of commercial buildings, The Structural Engineer, October 2012

[top]Resources

- The whole story – From cradle to grave

- Carbon footprint tool for buildings

- Steel construction – Embodied carbon

- Target Zero – Cost effective routes to carbon reduction

Target Zero design guides:

- Guidance on the design and construction of sustainable, low carbon office buildings

- Guidance on the design and construction of sustainable, low carbon warehouse buildings

- Guidance on the design and construction of sustainable, low carbon supermarket buildings

- Guidance on the design and construction of sustainable, low carbon mixed-use buildings

- Guidance on the design and construction of sustainable, low carbon school buildings

[top]See also

- Recycling and reuse

- Target Zero

- The recycling and reuse survey

- End of life LCA and embodied carbon data for common framing materials