Brent Civic Centre

Article in Construction News Special – Steel Spotlight, 29/11/12

To the beat of the drum

By Ruby Kitching

The Brent Civic Centre in Engineers Way, London, is an apt location for the UK’s greenest public

office building. It also boasts some of the most exquisite steelwork detailing in the country.

Local town halls have certainly changed with the times and London Borough of Brent’s new £100 million BREEAM Outstanding council offices, which are being built on the site of a former car park, are no exception. Brent Civic Centre, the greenest public office building in the country (see below), is as much a place for the council to carry out its operations as it is for the community to come together to use library services, a café and public gardens. Located in the shadow of Wembley Stadium and adjacent to Wembley Arena, the building is a welcome addition to the area, providing a much-needed hub.

Architect Hopkins with structural engineer URS, main contractor Skanska and steelwork contractor Bourne Construction Engineering are involved with the steel and concrete building, which has been designed to be functional, welcoming and inspiring. The steelwork was completed in October 2012.

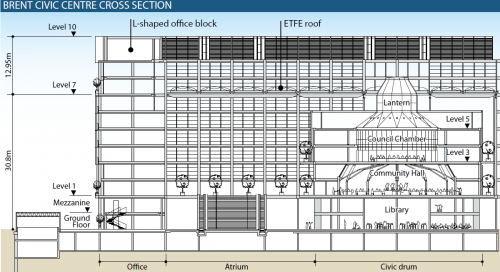

An L-shaped office block, with its long leg to the back of the site, will neatly accommodate up to 2,300 staff, who are currently spread over 14 different buildings around the borough. A steel framed, south-facing glass fronted atrium occupies the full height of the structure and connects the council offices to the civic building, a drum-shaped building which has a more open and inviting feel. The south-facing façade is fully glazed and delicately supported by a cable truss system.

Taking the limelight is the nine-storey drum-shaped civic building. Surrounded by open terraces with a central lantern feature nestled in the centre, the spaces created are breathtaking.

“The architectural intent was clear from day one – high spec finishes and carefully detailed connections. Every detail is expressed,” says Bourne Construction Engineering construction director Charlie Rowell. He adds that the 1,000 tonnes of steel in the project are prominent in the building’s overall structural and architectural scheme.

The public will enter the development via the full-height atrium, which is topped by ETFE pillows (the plastic material made famous in the biomes of Cornwall’s Eden project), which also spans across the civic drum.

A step up

A grand set of steps rise up from the ground floor of the atrium to reach the council services and offices. The civic drum, which will house a library, community hall, café, council chambers and shops, is also accessed via the atrium.

Interfaces between the structural steelwork and structural concrete elements of the building were a challenge due to different tolerances, particularly on the two end bays of the L-shaped office block, which feature steel-framed and cross-braced glazed walls.

“The external columns and cross-bracing steelwork was erected prior to casting of the edge beams, so the end bays had to be supported by falsework until the floors had been post-tensioned and the edge beams cast,” says Skanska senior project manager Paul Roberts.

Temporary supports were also required to support a suspended mezzanine level between ground and first floor of the office block. When the mezzanine slab had been post-tensioned, steel hangers from first floor level could be connected up to support the slab, and the temporary supports removed.

The 31 m-high atrium roof is supported by five, 30 m-long steel plate girder I beams. These are supported at their ends by columns on the interior face of the office block and civic drum. At 950 mm deep and 350 mm wide, the beams and their associated steelwork create a 7.5 m grid which is in-filled by ETFE pillows.

Steel members were designed to arrive on site in their longest possible lengths to reduce the amount of time spent on site splicing sections together, as well as to reduce the risk of working at height. The beams each arrived in 15 m-long sections and were lifted using tower cranes, which were designed specifically for the weight and reach required to install these members.

Running along the top of these beams are stool fixings which support insulated gutters. Since the ETFE pillows are under constant pressure to stay inflated, the gutters also have a structural function to resist this pressure. As a result, the gutters have been made using 8 mm-thick plate and are 6 m long along straight lengths of beam. Cruciform shaped gutters measuring 1.5 m square complete the grid at intersections.

Connections made

Perimeter columns at ground floor support the first floor slab in the civic drum, above which a steel pinned connection receives an almost impossibly slender 23 m-long steel circular hollow section column. This 406 x 10 mm-thick circular hollow section arrived on site in two pieces – a lower section 15 m long and an upper section at 8 m.

The columns, which support only the ETFE roof steelwork, were supported using temporary struts until all connections were made.

When it came to the concrete/ steel interfaces, careful sequencing was required.

“Because we had to accommodate a lot of movement, we cast endplates into concrete columns during column construction and fin plates were welded on after post-tensioning to achieve the millimetre accuracy required to connect with [atrium] steelwork,” says Mr Roberts.

Being so close to Wembley Stadium meant that erection of some of the external columns had to work around match days.

“Due to the constraints of the project programme, we had to sequence it very carefully so that we could erect the columns during the FA Cup final,” recalls Bourne senior site manager David Loan.

Mobile cranes were mobilised into the street outside the stadium just as the match started and the column had to be erected and plant cleared before the match finished.

“We were hoping for extra time, even penalties,” he jokes.

The slick operation was only made possible because the steel could be programmed to arrive just in time and be fixed to connections already prepared in the existing structure.

“There was a lot of pre-planning and consideration for access and plant, but when it came to erection, the columns went up really easily,” says Mr Loan.

The building will be completed in June 2013.

Centre’s high score

The Civic Centre has received a BREEAM Outstanding rating from the Building Research Establishment with a score of 92.55, making it the greenest public office building in the country and the fourth greenest building worldwide. It has achieved this by incorporating sustainable materials, natural ventilation, a green transport plan including 250 cycle spaces, rainwater harvesting and a combined cooling, heating and power plant that uses waste vegetable oil.

A complex project

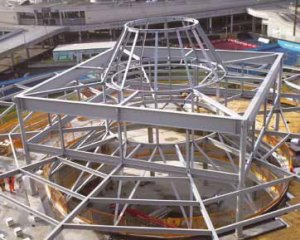

A double-storey height, 22 m-diameter community hall occupies the first floor of the civic drum. This column-free 1,000-seater space has been achieved using an elegant, exposed braced steel structure to support the level three floor slab, which was cast on a deep-trough profiled metal deck. Construction of this slab involved supporting it on temporary works prior to the braced steel structure being fixed.

The braced steelwork takes the form of cranked radial steel tubes which are supported off a perimeter ring-beam at mid-height of the room. Steel rods form a tension ring at the point where the tubes crank and are also used to provide cross-bracing between the tubes.

Finished off in a micaceous iron oxide appearance top coat which is part of the fire protection system and with exposed connections, the impression created is that of a bicycle wheel. But, due to the cranked ‘spokes’, the effect is more dome-like and ethereal. A winter garden surrounds the community hall and is supported off the main frame of the drum using composite steel construction.

A central steel and glass ‘lantern’ structure rises from level five of the civic drum, providing the roof over the double-storey height council chambers at level three. This lantern sits in the centre of the civic drum floor plates from levels five to seven, where the last storey height of lantern (levels seven to eight) are visible above the drum roof.

Erection of the lantern involved lowering the dismantled sections of a spider mobile elevating working platform onto level three, reassembling it and then lifting each steel section to a strict sequence, including hanging some members from level seven.

“Most projects don’t require this level of attention – pinned connections had to be millimetre perfect. Due to the complexity of this project, we’ve had an entire in-house engineering team on site since the end of January,” says Bourne senior site manager David Loan.

| Architect | Hopkins |

| Structural Engineer | URS |

| Steelwork Contractor | Bourne Construction Engineering |

| Main Contractor | Skanska |

| Client | Brent Council |