Difference between revisions of "Half-through bridges"

| (16 intermediate revisions by 2 users not shown) | |||

| Line 11: | Line 11: | ||

In a half-through bridge, the traffic is only partially inside the structural envelope – there are girders (or trusses) either side and a deck below but the girders are not as high as the traffic envelope and thus there cannot be any [[Bracing_systems#Plan_bracing|bracing]] to the top flanges (or chords). This means that a half-through bridge is in the form of a ‘trough’, i.e. it has a square U-shaped form. | In a half-through bridge, the traffic is only partially inside the structural envelope – there are girders (or trusses) either side and a deck below but the girders are not as high as the traffic envelope and thus there cannot be any [[Bracing_systems#Plan_bracing|bracing]] to the top flanges (or chords). This means that a half-through bridge is in the form of a ‘trough’, i.e. it has a square U-shaped form. | ||

| − | <gallery caption="Foxhole Colliery Bridge, Swansea" widths=380px heights= | + | <gallery caption="Foxhole Colliery Bridge, Swansea" perrow=2 widths=380px heights=230px> |

Image:Half-through1.jpg|During fabrication | Image:Half-through1.jpg|During fabrication | ||

Image:Half-through2.jpg|During construction | Image:Half-through2.jpg|During construction | ||

| Line 27: | Line 27: | ||

A typical layout for a half-through highway bridge is shown below. | A typical layout for a half-through highway bridge is shown below. | ||

{{#image_template:image=File:R5_Fig3.png|caption=Cross section layout, half-through highway bridge|align=left|width=600}} | {{#image_template:image=File:R5_Fig3.png|caption=Cross section layout, half-through highway bridge|align=left|width=600}} | ||

| − | The same constraint on construction depth is evident, and there is a similar need for clearance between traffic restraints (crash barriers) and the main girders (unless the structure is designed to resist impact loads at top flange level, which can be difficult to achieve). Requirements for highway restraint systems are given in | + | The same constraint on construction depth is evident, and there is a similar need for clearance between traffic restraints (crash barriers) and the main girders (unless the structure is designed to resist impact loads at top flange level, which can be difficult to achieve). Requirements for highway restraint systems are given in CD 377<ref name="No1">[https://www.standardsforhighways.co.uk/tses/attachments/1fe48581-82ba-4b6f-95a1-ee93309bd1b5?inline=true CD 377 Requirement for Road Restraint Systems. The Design Manual for Roads and Bridges. TSO]</ref> and these call for sufficient clearance behind the barrier for it to deflect without coming into contact with the structural girders. In practice, it may be difficult to provide the full lateral clearance and the issues then need to be debated with the Technical Approval Authority. |

{{#image_template:image=File:R5_Fig4.png|caption=Half-through road bridge|align=left|width=600}} | {{#image_template:image=File:R5_Fig4.png|caption=Half-through road bridge|align=left|width=600}} | ||

{{#image_template:image=File:R5_Fig5.png|align=left|width=600}} | {{#image_template:image=File:R5_Fig5.png|align=left|width=600}} | ||

| Line 49: | Line 49: | ||

There are two options for the open web girders – a triangulated truss (usually Warren type) and a Vierendeel girder. In the latter case, the parapet is often incorporated into the girders , with handrails within each panel. In both cases, the deck is usually a thin steel plate with transverse and longitudinal [[Stiffeners|stiffeners]]. | There are two options for the open web girders – a triangulated truss (usually Warren type) and a Vierendeel girder. In the latter case, the parapet is often incorporated into the girders , with handrails within each panel. In both cases, the deck is usually a thin steel plate with transverse and longitudinal [[Stiffeners|stiffeners]]. | ||

| − | <gallery caption="Warren truss half-through footbridges" widths=250px heights= | + | <gallery caption="Warren truss half-through footbridges" perrow=3 widths=250px heights=190px> |

Image:06_Wolverton.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | Image:06_Wolverton.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | ||

Image:Coalville_04.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | Image:Coalville_04.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | ||

Image:Park_Prewitt_27.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | Image:Park_Prewitt_27.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | ||

</gallery> | </gallery> | ||

| − | <gallery caption="Vierendeel girder half-through footbridges" widths=250px heights= | + | <br> |

| + | <gallery caption="Vierendeel girder half-through footbridges" perrow=3 widths=250px heights=190px> | ||

Image:Broomhill_06.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | Image:Broomhill_06.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | ||

Image:Elwy_Cycle_05.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | Image:Elwy_Cycle_05.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | ||

Image:Isfield_03.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | Image:Isfield_03.jpg|''(Image courtesy of Nusteel Structures Ltd.)'' | ||

</gallery> | </gallery> | ||

| + | <br> | ||

See [[Design of steel footbridges]] for more information. | See [[Design of steel footbridges]] for more information. | ||

| + | |||

| + | ==Case studies== | ||

| + | <gallery widths=180px heights=120px> | ||

| + | Image:River_Tame_Bridge.jpg|[[River Tame Crossing]] | ||

| + | Image:Ordsall_Chord-1a.jpg|[[Ordsall Chord, Manchester|Water Street bridges, Ordsall Chord, Manchester]] | ||

| + | Image:Lincoln_Eastern_Bypass-1a.jpg|[[Lincoln Eastern Bypass Railway Bridge]] | ||

| + | </gallery> | ||

==References== | ==References== | ||

| Line 67: | Line 76: | ||

*[[Media:SCI_P318.pdf|Iles, D.C. (2004) Design guide for steel railway bridges (P318) SCI]] | *[[Media:SCI_P318.pdf|Iles, D.C. (2004) Design guide for steel railway bridges (P318) SCI]] | ||

*[[Media:BCSA_51-10.pdf|Steel Bridges: A practical approach to design for efficient fabrication and construction. (51/10). BCSA]] | *[[Media:BCSA_51-10.pdf|Steel Bridges: A practical approach to design for efficient fabrication and construction. (51/10). BCSA]] | ||

| − | *[[Media:SCI_P185.pdf|Hendy, C.R.; | + | *[[Media:SCI_P185-SBG7.pdf|Hendy, C.R.; Cooper, M.C. (2025) Steel Bridge Group: Guidance Notes on best practice in steel bridge construction (7th Issue). (P185). SCI]] |

| − | **[[Media: | + | **[[Media:GN-1-10.pdf|Guidance Note 1.10 Half through bridges]] |

| − | **[[Media: | + | **[[Media:GN-2-10.pdf|Guidance Note 2.10 Steel deck plate for footbridges]] |

==See also== | ==See also== | ||

| Line 84: | Line 93: | ||

==External links== | ==External links== | ||

| − | *[ | + | *[https://www.standardsforhighways.co.uk/dmrb/ Highways England DMRB (Design Manual for Roads and Bridges)] |

| − | *[ | + | *[https://www.standardsforhighways.co.uk/mchw Highways England MCDHW (Manual of Contract Documents for Highway Works)] |

*[http://www.steel-sci.com/the-steel-bridge-group.html The Steel Bridge Group (SBG)] | *[http://www.steel-sci.com/the-steel-bridge-group.html The Steel Bridge Group (SBG)] | ||

[[Category:Bridges]] | [[Category:Bridges]] | ||

[[Category:Index of main articles]] | [[Category:Index of main articles]] | ||

Latest revision as of 11:59, 25 February 2026

A ‘half-through’ bridge configuration provides a solution for small and medium span bridges where the depth available between the trafficked surface (top of rails for a railway bridge) and the clearance level beneath the bridge is too shallow to accommodate the structural elements spanning across the bridge supports. This form of construction is more commonly seen in railway bridges and footbridges, but is sometimes used for highway bridges. This article provides an overview of this form of construction.

[top]Definition of ‘half-through’

A bridge provides a running surface for the traffic that crosses it and to ensure minimum interface issues it is best to arrange all the structural elements below that surface – i.e. the traffic runs on top of the bridge structure. But the depth of structure (including the thickness of surfacing or ballast) that is needed may in some cases be too great to be accommodated between the level of the trafficked surface (as dictated by levels adjacent to the bridge and by maximum gradients) and the level of minimum clearance above the ground, river, road or railway below.

In such cases, a different structural arrangement can be adopted, in which the traffic runs through the structural envelope. There then are two basic options – a ‘through’ configuration and a ‘half-through’ configuration.

In a ‘through bridge’ the traffic is completely inside the structural envelope – typically the traffic runs inside a truss, with the trusses either side of the carriageway, top bracing above the carriageway and the deck that directly supports the traffic below.

In a half-through bridge, the traffic is only partially inside the structural envelope – there are girders (or trusses) either side and a deck below but the girders are not as high as the traffic envelope and thus there cannot be any bracing to the top flanges (or chords). This means that a half-through bridge is in the form of a ‘trough’, i.e. it has a square U-shaped form.

- Foxhole Colliery Bridge, Swansea

This article illustrates the forms of half-through bridges. The design issues associated with the use of a half-through construction are discussed separately.

[top]Forms of half-through bridge

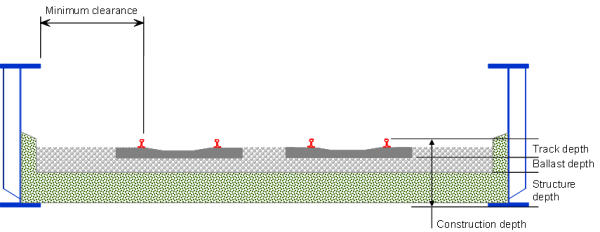

A typical cross sectional layout of a half-through plate girder railway bridge is shown below.

This image shows the key vertical dimension, the construction depth, which is the distance between the running surface of the rails and the lowest part of the soffit of the bridge. This vertical dimension is very tightly constrained when replacing a bridge under a railway line and over a roadway or another railway line, because it is extremely costly to re-grade a railway to increase the available vertical dimension and often physically difficult to depress a roadway beneath. Within the construction depth, the depth of track and ballast both have to be accommodated and the designer therefore has to provide a very shallow structural support system. That structural support spans transversely to longitudinal girders either side of the track and the girders span to the abutments or intermediate supports.

With the half-through form, lateral clearance has to be provided between the railway and the plate girders on either side. The clearance is needed both for the ‘swept envelope’ of the railway traffic and for access ways beside the track. Alternative arrangements for access ways outside the girders can sometimes be used, which reduces the clearance needed inside the girders, and where the girders extend upward only a small distance above the rail level, the distance from the track can sometimes be reduced further. Guidance on these alternative arrangements is given in SCI P318, which also lists the relevant railway standards.

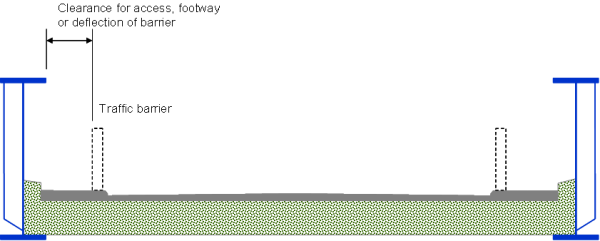

A typical layout for a half-through highway bridge is shown below.

The same constraint on construction depth is evident, and there is a similar need for clearance between traffic restraints (crash barriers) and the main girders (unless the structure is designed to resist impact loads at top flange level, which can be difficult to achieve). Requirements for highway restraint systems are given in CD 377[1] and these call for sufficient clearance behind the barrier for it to deflect without coming into contact with the structural girders. In practice, it may be difficult to provide the full lateral clearance and the issues then need to be debated with the Technical Approval Authority.

[top]Deck construction

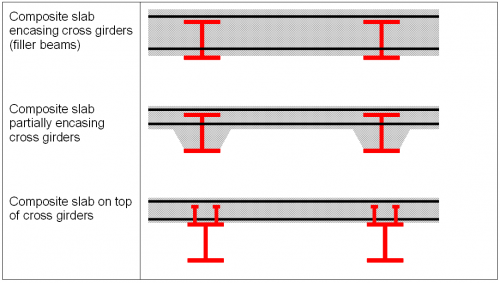

To achieve minimum structural depth, a composite beam and slab arrangement is usually adopted for the deck in railway and highway bridges. Three alternative beam and slab arrangements are shown below. In each case, the cross girders are connected to the main girders with end plate connection details.

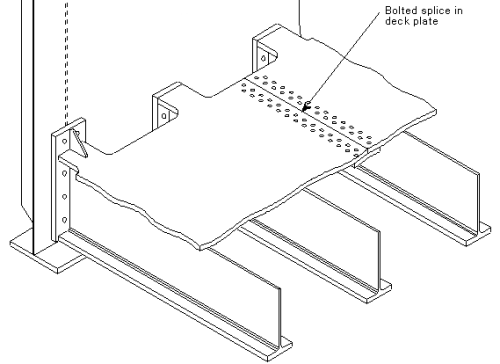

In some railway bridges, steel decks are used; the arrangement of transversely stiffened deck and its connection to the main girder is shown below. All the connections between cross girders and main girders are bolted; the deck plate is not directly connected.

[top]U-frame configuration

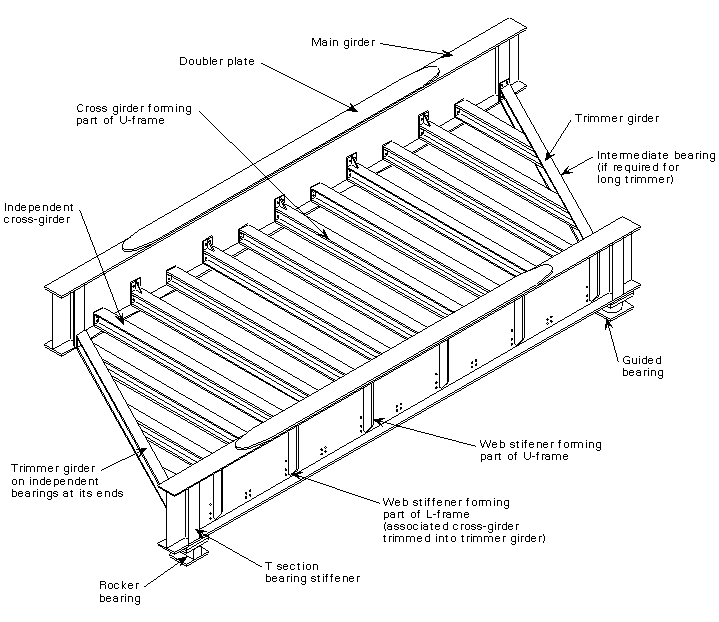

Whether the deck is composite or steel, the configuration of the whole bridge, main girders and cross girders is usually similar to that shown right.

In the Figure it may be noted that, although the bridge is skew, the cross girders span square to the main girders and alternate cross girders align with vertical web stiffeners, forming a rectangular U-frame. It is this frame that provides the lateral restraint to the top (compression) flange and the design of the U-frame is fundamental to the performance of the bridge.

The use of doubler plates to provide sufficient flange areas, as shown, is common on railway bridges.

[top]Half-through footbridges

Half-through steel bridges are a common solution for pedestrian and cycleway bridges. The footway/cycleway is relatively narrow and a stiffened steel plate deck can easily span between open web main girders on either side.

There are two options for the open web girders – a triangulated truss (usually Warren type) and a Vierendeel girder. In the latter case, the parapet is often incorporated into the girders , with handrails within each panel. In both cases, the deck is usually a thin steel plate with transverse and longitudinal stiffeners.

- Warren truss half-through footbridges

- Vierendeel girder half-through footbridges

See Design of steel footbridges for more information.

[top]Case studies

[top]References

[top]Resources

- Iles, D.C. (2004) Design guide for steel railway bridges (P318) SCI

- Steel Bridges: A practical approach to design for efficient fabrication and construction. (51/10). BCSA

- Hendy, C.R.; Cooper, M.C. (2025) Steel Bridge Group: Guidance Notes on best practice in steel bridge construction (7th Issue). (P185). SCI

[top]See also

- Shear connection in composite bridge beams

- Design for half-through construction

- Design of steel footbridges

- Fatigue design of bridges

- Stiffeners

- Connections in bridges

- Bridge articulation and bearing specification

- Skew bridges

- Design for steel bridge construction