Difference between revisions of "Cost planning - Healthcare buildings"

Zoe Williams (talk | contribs) |

|||

| (19 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

The [[Healthcare_buildings|healthcare sector]] can have exacting requirements for flexibility, specialist space, programme and vibration performance. Structural steelwork provides a number of frame solutions that respond to these key requirements including standard steel construction, [[Floor_systems#Shallow floors|shallow floors]], [[Long-span_beams|long span construction]] and [[Steel_construction_products#Cellular beams|cellular beams]]. | The [[Healthcare_buildings|healthcare sector]] can have exacting requirements for flexibility, specialist space, programme and vibration performance. Structural steelwork provides a number of frame solutions that respond to these key requirements including standard steel construction, [[Floor_systems#Shallow floors|shallow floors]], [[Long-span_beams|long span construction]] and [[Steel_construction_products#Cellular beams|cellular beams]]. | ||

| − | A steel frame can provide a number of [[The_case_for_steel|advantages]], including [[The_case_for_steel#Speed of construction|programme benefits]] where rapid delivery is often a critical project success factor, [[The_case_for_steel#Flexibility for changing times|flexible layouts]] and efficient [[Service_integration|services integration]] as well as the provision of a range of different functions, loadings and spans in an efficient and economic manner. The realisation of such advantages is evident in the latest [[#External links|Construction Markets]] survey commissioned by the BCSA and Steel for Life, which shows that in | + | A steel frame can provide a number of [[The_case_for_steel|advantages]], including [[The_case_for_steel#Speed of construction|programme benefits]] where rapid delivery is often a critical project success factor, [[The_case_for_steel#Flexibility for changing times|flexible layouts]] and efficient [[Service_integration|services integration]] as well as the provision of a range of different functions, loadings and spans in an efficient and economic manner. The realisation of such advantages is evident in the latest [[#External links|Construction Markets]] survey commissioned by the BCSA and Steel for Life, which shows that in 2024 steel frames accounted for 50.8% of all healthcare construction in the UK compared with 31.5% for insitu and precast concrete. |

This article focuses on the cost factors and the [[Cost_planning_through_design_stages|cost planning]] of steel framed [[Healthcare buildings|healthcare buildings]], specifically hospitals and smaller healthcare centres. However, many of the characteristics examined are also relevant to other healthcare buildings and can be considered during [[Cost_planning_through_design_stages|cost planning]] across the sector in general. It builds on the general guidance on the [[Cost of structural steelwork|cost of structural steelwork]], and [[Cost planning through design stages|cost planning through design stages]] for structural steel framed buildings by considering the [[#Heathcare buildings: Typical characteristics|typical design and construction characteristics]] of hospitals and health centres and reviews how they impact on frame selection. It explores the [[#Key frame cost drivers for healthcare buildings|key cost drivers]] for the healthcare sector and the principal factors to consider when using [[Cost_of_structural_steelwork#The_cost_table|standard cost ranges]] to ensure that realistic frame costs are achieved. | This article focuses on the cost factors and the [[Cost_planning_through_design_stages|cost planning]] of steel framed [[Healthcare buildings|healthcare buildings]], specifically hospitals and smaller healthcare centres. However, many of the characteristics examined are also relevant to other healthcare buildings and can be considered during [[Cost_planning_through_design_stages|cost planning]] across the sector in general. It builds on the general guidance on the [[Cost of structural steelwork|cost of structural steelwork]], and [[Cost planning through design stages|cost planning through design stages]] for structural steel framed buildings by considering the [[#Heathcare buildings: Typical characteristics|typical design and construction characteristics]] of hospitals and health centres and reviews how they impact on frame selection. It explores the [[#Key frame cost drivers for healthcare buildings|key cost drivers]] for the healthcare sector and the principal factors to consider when using [[Cost_of_structural_steelwork#The_cost_table|standard cost ranges]] to ensure that realistic frame costs are achieved. | ||

| Line 38: | Line 38: | ||

Structural steelwork provides solutions for the efficient distribution and [[Service_integration|integration of services]]. [[Floor_systems#Shallow floors|Shallow floor systems]] provide a flat soffit with the slabs and beams within the same zone at a minimised floor depth, which gives maximum flexibility in services distribution routes. Where a long span structural solution is considered, the use of [[Long-span_beams#Cellular composite beams|cellular beams]] with multiple regular web openings can provide flexibility in the initial installation and for future reconfigurations as well as reducing the total depth of structural floor plus service zone. | Structural steelwork provides solutions for the efficient distribution and [[Service_integration|integration of services]]. [[Floor_systems#Shallow floors|Shallow floor systems]] provide a flat soffit with the slabs and beams within the same zone at a minimised floor depth, which gives maximum flexibility in services distribution routes. Where a long span structural solution is considered, the use of [[Long-span_beams#Cellular composite beams|cellular beams]] with multiple regular web openings can provide flexibility in the initial installation and for future reconfigurations as well as reducing the total depth of structural floor plus service zone. | ||

| − | For healthcare buildings adopting a standard 7-9m repetitive grid, such as small health centres, the steel frame cost range is typically between | + | For healthcare buildings adopting a standard 7-9m repetitive grid, such as small health centres, the steel frame cost range is typically between £149 and £181 per m<sup>2</sup> GIFA ([[#External links|BCIS]] location index 100) assuming a frame weight of around 55kg/m<sup>2</sup> GIFA, which is similar to 'Low rise' in the [[Cost_of_structural_steelwork#The_cost_table|cost table]] below (low rise, short span, repetitive grid / sections, easy access). However, where the proposed building is higher rise, such as is typical for hospital buildings, or where a [[Long-span_beams|long span]] or [[Long-span_beams#Cellular composite beams|cellular beam]] solution is adopted, the frame cost will increase as the steel frame weight per m<sup>2</sup> GIFA will be higher and reference should be made to the cost range for 'High rise' of £251 to £283 per m<sup>2</sup> GIFA ([[#External links|BCIS]] location index 100) for a frame weight of around 90kg/m<sup>2</sup>. It should however be noted that some specialist functions and facilities with particular design requirements will sit outside this range. |

{|class="wikitable" width=750 style="text-align: center" | {|class="wikitable" width=750 style="text-align: center" | ||

| − | |+'''Table of indicative cost ranges ( | + | |+'''Table of indicative cost ranges (Q3, 2025) based on Gross Internal Floor Area (GIFA)''' |

|- | |- | ||

!colspan="2"|'''Type'''!!'''GIFA Rate (£/m<sup>2</sup>)<br>BCIS Index 100''' | !colspan="2"|'''Type'''!!'''GIFA Rate (£/m<sup>2</sup>)<br>BCIS Index 100''' | ||

|- | |- | ||

| − | |style="text-align: left" rowspan="3"|Frame||style="text-align: left"|Low rise, short spans, repetitive grid / sections, easy access (55kg/m<sup>2</sup> steelwork)|| | + | |style="text-align: left" rowspan="3"|Frame||style="text-align: left"|Low rise, short spans, repetitive grid / sections, easy access (55kg/m<sup>2</sup> steelwork)||158 - 191 |

|- | |- | ||

| − | |style="text-align: left"|High rise, long spans, easy access, repetitive grid (90kg/m<sup>2</sup> steelwork)|| | + | |style="text-align: left"|High rise, long spans, easy access, repetitive grid (90kg/m<sup>2</sup> steelwork)||266 - 299 |

|- | |- | ||

| − | |style="text-align: left"|High rise, long spans, complex access, irregular grid, complex elements (110kg/m<sup>2</sup> steelwork)|| | + | |style="text-align: left"|High rise, long spans, complex access, irregular grid, complex elements (110kg/m<sup>2</sup> steelwork)||302 - 357 |

|- | |- | ||

| − | |style="text-align: left" rowspan="2"|Floor||style="text-align: left"|Composite floors, metal decking and lightweight concrete topping|| | + | |style="text-align: left" rowspan="2"|Floor||style="text-align: left"|Composite floors, metal decking and lightweight concrete topping||90 - 140 |

|- | |- | ||

| − | |style="text-align: left"|Hollowcore precast concrete composite floor with concrete topping|| | + | |style="text-align: left"|Hollowcore precast concrete composite floor with concrete topping||137 - 193 |

|- | |- | ||

| − | |style="text-align: left" rowspan="2"|Fire protection||style="text-align: left"|Factory applied intumescent (60 minutes resistance)|| | + | |style="text-align: left" rowspan="2"|Fire protection||style="text-align: left"|Factory applied intumescent (60 minutes resistance)||29 - 40 |

|- | |- | ||

| − | |style="text-align: left"|Factory applied intumescent (90 minutes resistance)|| | + | |style="text-align: left"|Factory applied intumescent (90 minutes resistance)||36 -58 |

|- | |- | ||

| − | |style="text-align: left" rowspan="2"|Portal frames||style="text-align: left"|Large span single storey building with low eaves (6 - 8 m)|| | + | |style="text-align: left" rowspan="2"|Portal frames||style="text-align: left"|Large span single storey building with low eaves (6 - 8 m), 35kg/m<sup>2</sup> steelwork||114 - 149 |

|- | |- | ||

| − | |style="text-align: left"|Large span single storey building with high eaves (10 - 13 m)|| | + | |style="text-align: left"|Large span single storey building with high eaves (10 - 13 m), 45kg/m<sup>2</sup> steelwork||139 - 178 |

|} | |} | ||

<br> | <br> | ||

| Line 110: | Line 110: | ||

|} | |} | ||

<br> | <br> | ||

| − | ''Tests have been carried out on both long and medium span structures with floor build ups varying from 140mm to 300mm deep and have demonstrated that [[Composite_construction|composite floor construction]] can satisfy the NHS Acoustic design manual HTM 08-01<ref name="HTM08-01">[https://www. | + | ''Tests have been carried out on both long and medium span structures with floor build ups varying from 140mm to 300mm deep and have demonstrated that [[Composite_construction|composite floor construction]] can satisfy the NHS Acoustic design manual HTM 08-01<ref name="HTM08-01">[https://www.england.nhs.uk/publication/health-sector-buildings-acoustic-design-requirements-htm-08-01/ Health Technical Memorandum 08-01, Acoustics. Department of Health, 2013]</ref> [[Floor_vibrations#Regulations and design rules|limits for vibration]], as well as showing that for long span steel structures, the mass of the long span sections reduces the magnitude of the [[Floor_vibrations#Types of response|vibration response]] rather than creating additional vibration. All measured [[Floor_vibrations#Design criteria for vibrations|response factors]] were significantly below the limiting value of 1.'' |

The [[Floor_vibrations#Design criteria for vibrations|vibration criteria]] for each function must be established early in the design process to ensure all considerations are captured in the developing architectural and structural design and cost estimates. | The [[Floor_vibrations#Design criteria for vibrations|vibration criteria]] for each function must be established early in the design process to ensure all considerations are captured in the developing architectural and structural design and cost estimates. | ||

Latest revision as of 08:04, 19 September 2025

The healthcare sector can have exacting requirements for flexibility, specialist space, programme and vibration performance. Structural steelwork provides a number of frame solutions that respond to these key requirements including standard steel construction, shallow floors, long span construction and cellular beams.

A steel frame can provide a number of advantages, including programme benefits where rapid delivery is often a critical project success factor, flexible layouts and efficient services integration as well as the provision of a range of different functions, loadings and spans in an efficient and economic manner. The realisation of such advantages is evident in the latest Construction Markets survey commissioned by the BCSA and Steel for Life, which shows that in 2024 steel frames accounted for 50.8% of all healthcare construction in the UK compared with 31.5% for insitu and precast concrete.

This article focuses on the cost factors and the cost planning of steel framed healthcare buildings, specifically hospitals and smaller healthcare centres. However, many of the characteristics examined are also relevant to other healthcare buildings and can be considered during cost planning across the sector in general. It builds on the general guidance on the cost of structural steelwork, and cost planning through design stages for structural steel framed buildings by considering the typical design and construction characteristics of hospitals and health centres and reviews how they impact on frame selection. It explores the key cost drivers for the healthcare sector and the principal factors to consider when using standard cost ranges to ensure that realistic frame costs are achieved.

The article also examines the specialist design consideration of vibration performance in the context of structural frame material and design, and demonstrates how this requirement can be addressed while still capturing the cost and programme advantages of a structural steel solution.

[top]Healthcare buildings: Typical characteristics

The healthcare sector includes numerous building types and uses. However, the key typical requirements of the sector can be identified through a consideration of hospital buildings and smaller health centres.

Even within the narrower focus of hospital buildings, there are variations in design requirements and characteristics between hospitals, which can range in size and function, such as general hospitals, specialist centres and teaching hospitals. However, functions such as consultation rooms, ancillary space and bed space are common across the sector, so a number of typical requirements can be identified.

Flexibility is important as hospitals need to accommodate a range of functions and spaces and, as the lifespans of the built assets are long, there may be changes in the functions and locations provided. Adaptability is also important to enable efficient future reconfiguration to maximise value over the life of the building.

Hospitals also have particularly high servicing requirements compared with other building types, so the efficient integration and distribution of services is important to maintain maximum flexibility and avoid significant impacts on floor-to-floor heights.

Acoustic performance is also a significant consideration, as privacy and the patient experience are key success factors. Unlike some sectors where early design and cost studies can focus on the benefits of insitu or precast concrete soffits inherently providing a “finish”, such as for education buildings, this is less relevant for hospital buildings as, due to both infection control and acoustic performance requirements, exposed soffits are less common.

Where hospital buildings accommodate specialist functions, such as operating theatre space, they also have stringent vibration performance standards, which require close examination during the design stages to ensure that the architectural design allows this to be achieved as efficiently as possible.

Speed of delivery of the building is also a common requirement for hospital buildings and the healthcare sector in general, not only to bring new facilities on line as soon as possible, but also, where construction is proposed on occupied hospital sites, to minimise disruption to existing facilities.

As outlined above, since the majority of hospital buildings are long-term assets, whole-life cost and value are also considerations, with not only cost of construction but also costs in use being a key part of the decision making process.

Smaller health centres, which are typically staffed by GPs and nurses and offer family practice and dental care services, can also provide services such as pharmacy, laboratory and, in larger facilities, minor medical procedures. These buildings share a number of design requirements with hospital buildings, particularly flexibility and adaptability, programme requirements and whole-life cost considerations. While vibration performance is less important as they do not typically contain specialised functions, acoustic performance and control of transfer of noise to maintain privacy is still an important consideration.

[top]Healthcare buildings: Structural steel frames

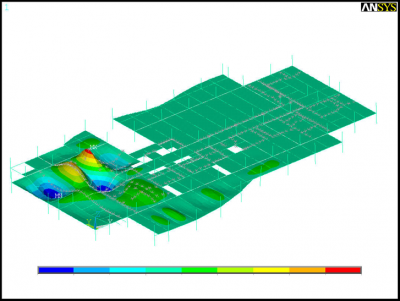

(Image courtesy of of Kloeckner Metals UK Westok)

There are a number of structural steel frame solutions that can be adopted to address the typical design drivers of buildings in the healthcare sector outlined above.

For most healthcare functions, including offices, consulting rooms and wards, a 7-9m standard grid is adequate and will provide a good level of flexibility. Standard steel construction provides quicker erection time than other frame types and potential benefits in substructure construction due to typically lighter frame weights. Floor systems such as a composite metal deck with concrete topping or precast concrete planks are supported on downstand beams and services can be suspended from the soffit of the floor slab and distributed with flexibility within each structural bay.

For buildings where future flexibility is particularly important, or where design features such as atria require it, a long span structural steel frame can be used to provide column free internal space and maximum floor plate flexibility.

Structural steelwork provides solutions for the efficient distribution and integration of services. Shallow floor systems provide a flat soffit with the slabs and beams within the same zone at a minimised floor depth, which gives maximum flexibility in services distribution routes. Where a long span structural solution is considered, the use of cellular beams with multiple regular web openings can provide flexibility in the initial installation and for future reconfigurations as well as reducing the total depth of structural floor plus service zone.

For healthcare buildings adopting a standard 7-9m repetitive grid, such as small health centres, the steel frame cost range is typically between £149 and £181 per m2 GIFA (BCIS location index 100) assuming a frame weight of around 55kg/m2 GIFA, which is similar to 'Low rise' in the cost table below (low rise, short span, repetitive grid / sections, easy access). However, where the proposed building is higher rise, such as is typical for hospital buildings, or where a long span or cellular beam solution is adopted, the frame cost will increase as the steel frame weight per m2 GIFA will be higher and reference should be made to the cost range for 'High rise' of £251 to £283 per m2 GIFA (BCIS location index 100) for a frame weight of around 90kg/m2. It should however be noted that some specialist functions and facilities with particular design requirements will sit outside this range.

| Type | GIFA Rate (£/m2) BCIS Index 100 | |

|---|---|---|

| Frame | Low rise, short spans, repetitive grid / sections, easy access (55kg/m2 steelwork) | 158 - 191 |

| High rise, long spans, easy access, repetitive grid (90kg/m2 steelwork) | 266 - 299 | |

| High rise, long spans, complex access, irregular grid, complex elements (110kg/m2 steelwork) | 302 - 357 | |

| Floor | Composite floors, metal decking and lightweight concrete topping | 90 - 140 |

| Hollowcore precast concrete composite floor with concrete topping | 137 - 193 | |

| Fire protection | Factory applied intumescent (60 minutes resistance) | 29 - 40 |

| Factory applied intumescent (90 minutes resistance) | 36 -58 | |

| Portal frames | Large span single storey building with low eaves (6 - 8 m), 35kg/m2 steelwork | 114 - 149 |

| Large span single storey building with high eaves (10 - 13 m), 45kg/m2 steelwork | 139 - 178 | |

As with all building types, along with a consideration of standard cost ranges, there are a number of cost drivers that must be examined individually during cost planning to determine project specific frame costs.

[top]Key frame cost drivers for healthcare buildings

While the typical requirements for healthcare buildings influence frame solutions and make the standard cost ranges for structural steel frames a useful tool, it is also important to consider some of the elements that do vary from project to project throughout the cost planning process.

[top]Location, site constraints and site configuration

In particular, location and site constraints are key cost drivers for all types of building, influencing both the achievable design and the costs of construction. This is particularly relevant to the healthcare sector as construction often occurs on existing, occupied sites which, as well as impacting on design, can also impact on construction methodology and programme with limitations on noise, deliveries, working hours and restrictions on storage and craneage. Standard cost ranges based on relatively unconstrained sites will not include for the additional logistics and cost for preliminaries associated with constrained or city-centre sites with reduced access so this needs to be allowed for.

Site configuration will also have an impact on the building design in a number of areas, including floor plate configuration, grid, storey height and overall building height. Where the structural grid has to change across the building to account for site factors or adjacent buildings, the efficiencies of repetition across the frame may not be realised. A less constrained site can enable a more regular grid to be set, and more repetitive structures provide both material cost and on-site erection efficiencies. The extent to which a proposed building is influenced by factors that reduce the level of repetition should be assessed during cost planning to determine if these restrictions can be overcome as they may result in additional costs above those captured in the standard frame cost ranges.

[top]Building height

Site constraints and configuration can also impact on overall building height, and therefore also on total frame cost. The frame cost for space provided on small floor plates across multiple storeys will differ from the same area provided on larger floor plates in a low rise building as the steel frame weight per kg/m2 GIFA will differ, with a higher weight required for multi-storey construction. An understanding of the likely building form and height is important even at the earliest cost planning stages.

[top]Facilities and specialist space

The facilities to be provided should also be reviewed during cost planning; the proportion of each type of space provided in the proposed building should be considered, as this will often directly impact the developing structural frame design. The inclusion of a number of different functions can reduce the regularity and repetition of the structure throughout the building, with hospital buildings tending to contain a greater variety of functions than smaller health centres.

As well as a consideration of the proposed mix of facilities, the proportion of specialist space with particular requirements will also need to be reviewed. In the healthcare sector, specialist functions, such as operating theatres, have strict vibration control requirements, and this will have an impact on the frame design and cost that is not considered as part of the standard cost ranges. Similarly, the requirements for and method of acoustic attenuation must be assessed and included in early cost estimates as this can vary depending on the frame adopted. An exposed soffit solution is unusual in this sector, with suspended ceilings typically specified for infection control purposes as well as contributing to the economic achievement of acoustic requirements, so allowances for suspended ceilings should typically be included for all frame types in early frame material cost comparisons.

[top]Design and procurement

Influenced by all the above factors, a structural grid of 7-9m spans is typical for both multi-storey hospitals and smaller health centres. Therefore, where a long span grid or cellular beam solution is considered as a response to flexibility, services integration, site configuration or function requirements, there may be a cost premium as the weight of the steel frame may have to increase to achieve the spans. However, it should be noted that while long spans and cellular beams will tend to have higher cost per tonne than a standard steel frame, the frame cost overall is competitive compared with other frame solutions to achieve the same span and can also offer lower foundation costs due to fewer columns being required.

It should also be noted that partnering and framework arrangements are common in healthcare, with projects procured under ProCure21+, Private Finance Initiatives and LIFT, so costs or solutions may already be set out with contractors. The procurement route will impact on the form of contract and supply chain, and benchmarked or cost ranges based on projects tendered in competition may not apply.

As with all projects, pressures on the design team during the development phase may tend towards only reviewing the comparative costs of different frame materials, but this is an overly simplistic approach as the frame design itself will also impact on the cost of associated elements. For example, varying structural zones of different solutions and configurations will result in different floor-to-floor heights, which will impact on cladding costs, and different frame weights will also impact on the design and cost of the substructure, programme and cost of preliminaries.

[top]Structural steel frames and vibration

The prevalence of sensitive functions in the healthcare sector makes vibration performance a particularly important factor.

For most multi-storey buildings, standard steel construction will meet the requirements without additional modifications. However, some specialist functions in the healthcare sector have more onerous performance criteria as occupants can perceive very low amplitudes of vibration and where the building contains motion-sensitive activities, such as surgery, it is important to minimise vibration frequency and magnitude.

When the last wave of new hospital construction began a decade or so ago, there was a perception that composite floors in steel structures provide a lower level of vibration damping than concrete. However, testing was carried out to demonstrate the ability of steel-framed composite floors to meet the strict requirements (see below) and as a result, the use of steel frames for hospital buildings significantly increased, as designers and contractors were able to more readily use structural steelwork and take advantage of the other benefits, such as speed of construction, long span and column free layouts and flexible services integration.

| Form of Construction | Fundamental frequency (Hz) | Response factor |

|---|---|---|

| Long-span composite beams of 11.3m span with a 300mm deep composite slab | 6.4 | 0.25 |

| Long-span composite beams of 15m span with a 175mm deep composite slab | 7.6 | 0.49 |

| Medium-span composite beams of 8.1m span with a 140mm deep composite slab | 8.0 | 0.21 |

Tests have been carried out on both long and medium span structures with floor build ups varying from 140mm to 300mm deep and have demonstrated that composite floor construction can satisfy the NHS Acoustic design manual HTM 08-01[1] limits for vibration, as well as showing that for long span steel structures, the mass of the long span sections reduces the magnitude of the vibration response rather than creating additional vibration. All measured response factors were significantly below the limiting value of 1.

The vibration criteria for each function must be established early in the design process to ensure all considerations are captured in the developing architectural and structural design and cost estimates.

Vibration performance is measured in terms of the response factor of the floor and this will be assessed during the design stages by the structural engineer through the use of design software or by following the design guidance and assessment methodologies set out in SCI P354. The Steel Construction: Floor Vibration publication is also relevant, and a useful web-based Floor response calculator is also available to swiftly evaluate the vibration response of floors.

Specialist guidance on the permitted level of vibration exists for the healthcare sector, and HTM 08-01[1] sets out the continuous vibration limits for different healthcare functions.

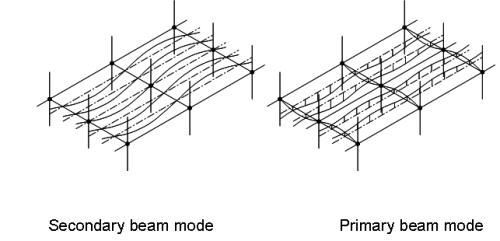

There is a clear difference in the vibration limits across the types of spaces commonly found within hospital buildings and the resulting structural design will need to accommodate these requirements. To maximise efficiencies, thought should be given to the locations of different functions at the early design stages, with functions of similar vibration requirements located together as far as is possible.

The architectural design can also aid the structural design through consideration of the location of circulation routes. Areas close to beams and columns are typically less responsive than the middle of slabs, so by locating routes closer to beams and columns some vibration issues can be eliminated. Shortening circulation corridors or breaking them up into smaller lengths will reduce walking durations and can prevent a resonant response building up in the floor structure.

A number of aspects of the structural design also need to be considered to ensure the floor performs as required, including floor construction, damping, floor loading and continuity and isolation of critical areas.

Metal deck composite floors and precast concrete units with a structural topping behave similarly when connected to the beams with shear connections or situated between beam flanges. However, when using precast units, it is important that they are fixed with shear studs or a structural topping is included to ensure the floor performs as a whole rather than as separate units, which may vibrate independently of each other.

When assessing the predicted vibration response of a structural frame it is important to establish the likely damping ratio, which is affected by the type of connectors and the degree of building fit out and furniture, as the level of damping will affect the duration of vibration response as well as its amplitude.

It is also important that the distributed mass assumed is representative of the mass when the building is in use as this affects the response factor of a floor at a given frequency. The higher the mass, the lower the response, so the weight of the structure and permanent loads such as ceilings and services should be considered to improve accuracy.

The vibration response of the floor can also be influenced by controlling the extent of floor plate participation. Where a greater mass is required to minimise vibration, greater floor plate continuity can be designed in. Alternatively, where specific areas are very sensitive to vibration, these areas can be isolated from the rest of the floor through construction joints at the edges or increasing the stiffness of the floor locally.

[top]References

[top]Resources

- Steel Insight 7 – Healthcare, April 2013, Building magazine

- SCI P354 Design of Floors for Vibrations- A New Approach

- Steel Construction: Floor Vibration, BCSA, 2016

- Floor response calculator

[top]See also

- Cost of structural steelwork

- Cost planning through design stages

- Healthcare buildings

- Concept design

- Service integration

- Braced frames

- Composite construction

- Floor systems

- Long-span beams

- Acoustics

- Floor vibrations

- Construction