Modular construction

‘Modular construction’ is a term used to describe the use of factory-produced pre-engineered building units that are delivered to site and assembled as large volumetric components or as substantial elements of a building. The modular units may form complete rooms, parts of rooms, or separate highly serviced units such as toilets or lifts. The collection of discrete modular units usually forms a self-supporting structure in its own right or, for tall buildings, may rely on an independent structural framework.

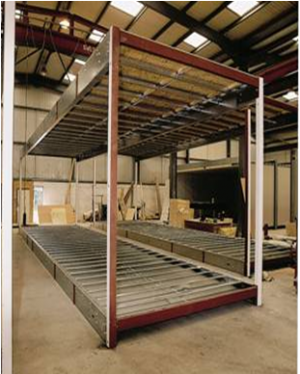

(Image courtesy of Portakabin)

The main sectors of application of modular construction are:

- Private housing

- Social housing

- Apartments and mixed-use buildings

- Educational sector and student residences

- Key worker accommodation and sheltered housing

- Public sector buildings, such as prisons and MoD buildings

- Health sector buildings

- Hotels.

Thousands of modules are manufactured annually in the UK. The largest markets for modular construction are in student residences, military accommodation and hotels, but the health sector is significant as it requires highly complex services and medical installations that can be commissioned and tested off-site.

[top]Attributes of modular construction

The use of modular and other lightweight forms of building construction is increasing. The benefits of modular construction, relative to more traditional methods, include:

- Economy of scale through repetitive manufacture

- Rapid installation on site (6-8 units per day)

- High level of quality control in factory production

- Low selfweight leading to foundation savings

- Suitable for projects with site constraints and where methods of working require more off-site manufacture

- Limited disruption in the vicinity of the construction site

- Useful in building renovation projects, such as roof top extensions

- Excellent acoustic insulation due to double layer construction

- Adaptable for future extensions, and ability to be dismantled easily and moved if required

- Robustness can be achieved by connecting the units together at their corners

- Stability of tall buildings can be provided by a braced steel or concrete core.

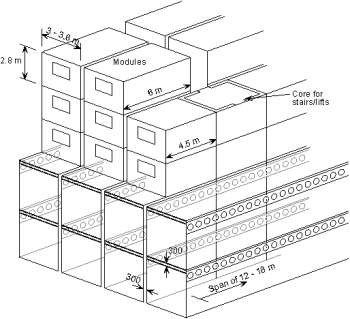

Modular construction is most commonly associated with cellular type buildings such as student residences or key worker accommodation. For these applications it has the following features:

- Suitable for buildings with multiple repeated units

- Size of units is limited by transport (3.6 m x 8 m is typical)

- Open-sided units can be created (by changing the floor orientation)

- Modules are stacked without usually needing an independent structure

- Self weight of 1.5 to 2 kN/m2

- 4 to 10 storeys (6 is usually the optimum)

- Fire resistance of 30 to 60 minutes provided

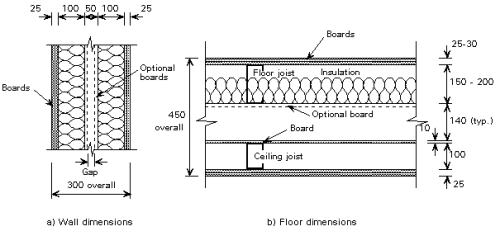

- Acoustic insulation is provided through double layer walls and floors.

The following table describes the various structural elements used in walls and floors of modules.

| Walls | Floors |

|---|---|

| Walls of modules comprise C sections of 75 to 150 mm depth. | Floors of modules comprise C sections of 150 to 250 mm depth. |

| Longitudinal walls are usually load-bearing and the end walls provide stability. | Ceiling is manufactured as a wall panel. |

| Open-sided modules can be created by longitudinal floor and ceiling joists – end walls become load bearing. | Open-sided modules use deeper floor joists or lattice joists of 250 to 400 mm depth. |

| Stability provided by cross flats or diaphragm action of boarding. | Corridor zone can be used to provide in-plane bracing in long buildings. |

| Double skin walls provide excellent acoustic insulation. | Double skin floor and ceiling provides excellent acoustic insulation. Mineral wool may be required between the joists. |

[top]Types of modules

The following types of modules may be used in the design of buildings using either fully modular construction or mixed forms of steel construction:

- 4-sided modules

- Partially open-sided modules

- Open-sided (corner-supported) modules

- Modules supported by a primary structural frame

- Non load bearing modules

- Mixed modules and planar floor cassettes

- Special stair or lift modules.

The structure of the modules consists mainly of light steel C sections that are cold rolled from strip steel to BS EN 10346[1]. Additional corner posts in the form of square hollow sections are often used.

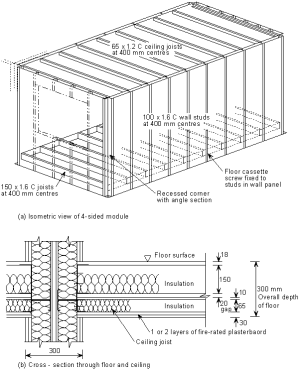

[top]4-sided modules

In this form of construction, modules are manufactured with four closed sides to create cellular type spaces designed to transfer the combined vertical load of the modules above and in-plane loads (due to wind action) through their longitudinal walls. The cellular space provided is limited by the transportation and installation requirements. Depending on location and exposure to wind action, the height of buildings in fully modular construction is in the range of 6 to 10 storeys.

Modules are manufactured from a series of 2D panels, beginning with the floor cassette, to which the four wall panels and ceiling panel are attached generally by screws. The walls transfer vertical loads and therefore the longitudinal walls of the upper module are designed to sit on the walls of the module below.

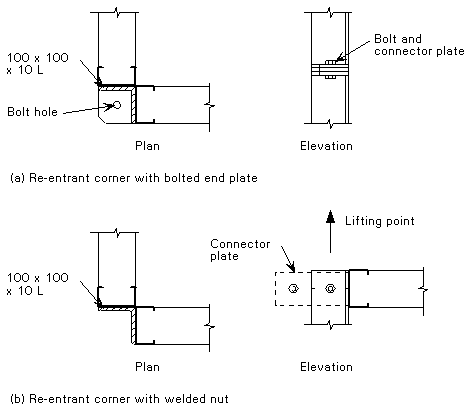

Additional steel angles may be introduced in the recessed corners of the modules for lifting and for improved stability. Module-to-module connections are usually in the form of plates that are bolted on site. Special lifting frames are used that allow the modules to be unhooked safely at height.

Details of 4-sided modules showing recessed corners with additional angle sections

Modules can be manufactured with integral balconies and a range of cladding materials can be pre-attached or installed on site. All walls are insulated, and are usually boarded externally for weather protection. Additional external insulation can be attached on site.

For low rise buildings, in plane bracing or diaphragm action of the board materials within the modules provides shear resistance, assisted by the module to module connections, which transfer the applied wind forces to the group of modules.

For buildings of 6 to 10 storeys height, a vertical bracing system is often located around an access core, and assisted by horizontal bracing in the corridor floor between the modules. For taller buildings, a steel podium frame may be provided on which the modules are stacked and supplemented by a concrete or steel core.

The maximum height of a group of modules is dependent on the stability provided under wind action. Various cases are presented in the table for scheme design (based on wind loading in the Midlands of England).

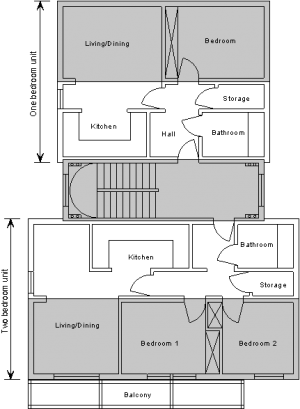

[top]Partially open-sided modules

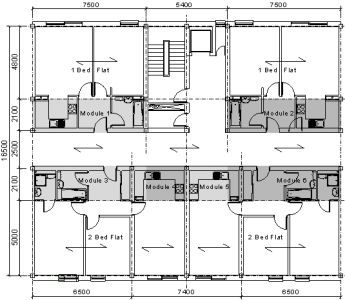

4-sided modules can be designed with partially open sides by the introduction of corner and intermediate posts and by using a stiff continuous edge beam in the floor cassette. The maximum width of opening is limited by the bending resistance and stiffness of the edge member in the floor cassette. Additional intermediate posts are usually square hollow sections (SHS), so that they can fit within the wall width.

Two modules can be placed together to create wider spaces. The compression resistance of the corner or internal posts controls the maximum height of the building, but 6 to 10 storeys can be achieved, as for fully modular construction.

Long modules can also be designed to include an integral corridor, as shown below. The length of the module may be limited by transport and site access but a length of up to 12 m is normally practical. Use of modules with integral corridors can improve the speed of construction by avoiding weather tightness problems during installation and finishing work.

The form of construction is similar to that of 4-sided modules, except for the use of additional posts, generally in the form of 70 x 70 to 100 x 100 SHS members. Balconies or other components can be attached to the corner or internal posts. Overall stability is provided by additional bracing located in the walls of the modules.

Stability of the modules is affected by their partially open sides; additional temporary bracing during lifting and installation may be necessary. A separate bracing system may also be required, as the partially open-sided modules may not possess sufficient shear resistance in certain applications. A typical building form in which larger apartments are created using partially open sided units is shown right.

[top]Open sided (corner-supported) modules

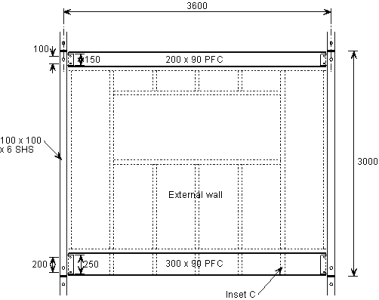

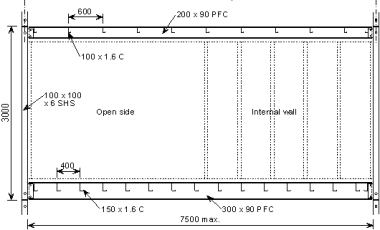

Modules may be designed to provide fully open sides by transfer of loads through the longitudinal edge beams to the corner posts. The framework of the module is often in the form of hot rolled steel members, such as Square Hollow Section (SHS) columns and Parallel Flange Channel (PFC) edge beams, that are bolted together.

A shallower parallel flange channel (PFC) section may be used to support the ceiling, but in all cases, the combined depth of the edge beams is greater than for 4-sided modules. Modules can be placed side by side to create larger open plan spaces, as required in hospitals and schools, etc.

The stability of the building generally relies on a separate bracing system in the form of X bracing in the separating walls. For this reason, fully open-ended modules are not often used for buildings more than three storeys high. Where used, infill walls and partitions within the modules are non load bearing, except where walls connected to the columns provide in plane bracing. The corner posts provide the compression resistance and are typically 100 x 100 SHS members. The edge beams may be connected to these posts by fin plates, which provide nominal bending resistance. End plates and proprietary ‘blind’ fixings to the SHS members may also be used. The corner posts possess sufficient compression resistance for use in buildings at least up to 10 storeys.

As open-sided modules are only stable on their own for one or two storeys, additional vertical and horizontal bracing is usually introduced. In-plane forces can be transferred by suitable connections at the corners of the modules.

An open-ended module is a variant of a 4-sided module in which a rigid end frame is provided, usually consisting of welded or rigidly connected Rectangular Hollow Sections (RHS). The rigid end frames are manufactured as part of the module or can be assembled as separate components.

A steel external framework comprising walkways or balconies may be also designed to provide stability. Modules using hot rolled steel framework can be designed to support concrete floors for use in medical and other applications, where strict control of vibrations is required.

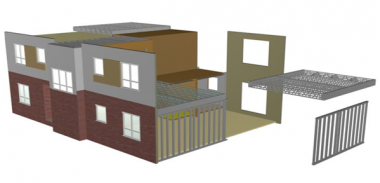

[top]Mixed modules and floor cassettes

In this ‘hybrid’ or mixed form of construction, long modules may be stacked to form a load bearing serviced core and floor cassettes span between the modules and load bearing walls. The modules are constructed in a similar way to that described for open-sided modules, but the loading applied to the side of the modules is significantly higher. Therefore, this mixed modular and panel form of construction is limited to buildings of 4 to 6 storey height. It is typically used in residential buildings, particularly of terraced form, comprising modular ‘cores’ for stairs, and highly serviced areas. The modules are arranged in a ‘spine’ through the building and the floors are attached to it. An example of this hybrid form of construction is shown.

[top]Modules supported by a primary structure

Modular units may be designed to be supported by a primary structure at a podium or platform level. In this case, the supporting columns are positioned at a multiple of the width of the modules (normally 2 or 3 modules). The beams are designed to support the combined loads from the modules above (normally a maximum of 4 to 6 storeys).

The supporting structure is designed conventionally as a steel framework with beams and columns that align with multiples of the module width, and provides open plan space at ground floor and below ground levels. This form of construction is very suitable for mixed retail, commercial and residential developments, especially for residential units above commercial areas or car parking, etc, particularly in urban projects.

Modules can be set back from the façade line. An example of a mixed development in Manchester is shown. The ground floor and below- ground car parking is a conventional composite structure.

(Image courtesy of The Design Buro, Rollalong and Ayrshire Framing)

Where the 4-sided modules are designed to be supported by steel or composite beams and the typical line load per supported floor is 15 kN/m, columns are placed at 6 to 8 m spacing. A column spacing of 7.2 m is suitable for below ground car parking. The depth of the podium type structure is 800 to 1000 mm, and spans of 10 to 18 m can be created below the podium, which are suitable for commercial applications and car parking.

The podium structure is generally braced to resist wind loads and a separate braced core is often used to stabilise the group of modules above the podium level. The module design is similar to that described for 4-sided modules. Wind loads can be transferred horizontally through the corridor floors.

Alternatively, non load bearing modules can be supported by a primary frame, and are installed as the construction proceeds. Modules can be disassembled in the future to leave the floor cassette supported by the beams. An example of the mixed use of modules and primary steel frame is shown below left. The modules are shown shaded and floor spans indicated.

An external steel structure, consisting of a façade structure that acts to stabilise the building, may also be used. Modules are placed internally within the braced steel frame, as shown in the MoHo project in Manchester (below right).

Mixed use of modules and long spanning floor with a primary steel frame

[top]Other types of modules

Various forms of other modular components have been used in major building projects.

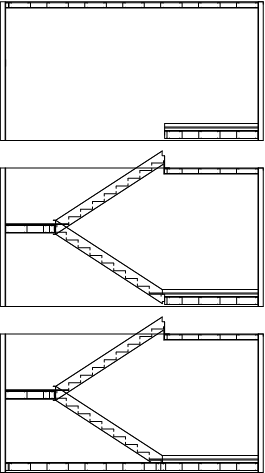

[top]Stair modules

Modular stairs may be designed as fully modular units and generally comprise landings and half landings with two flights of stairs. The landings and half landings are supported by longitudinal walls with additional angles or SHS members to provide local strengthening, if necessary. The stair modules rely for their stability on a base and top, which leads to use of a false landing. The open top and base of the wall may be strengthened by a Tee section, angle or similar members to transfer out-of-plane loads to the landing. SHS posts and bracing can be introduced in the walls to provide overall stability.

[top]Non load bearing modules

Non load bearing modules are of similar form to fully modular units, but are not designed to resist external loads, other than their own weight and the forces during lifting. They are used as toilet/bathroom units, plant rooms or other serviced units and are supported directly on a floor or by a separate structure. The walls and floor of these ‘pods’ are relatively thin (typically <100mm). The units are designed to be installed either as the construction proceeds or slid into place on the completed floor.

Compatibility of the floor depth in the module and in the floor elsewhere is achieved by one of four methods:

- Designing the depth of the floor of the module to be the same as the raised floor or acoustic layer elsewhere.

- Placing the module in a recess in the floor of the main structure.

- Designing the module without a floor (possible in small modules in which fitments are attached to the walls).

- Designing the modules to be supported on the bottom flange of Slimflor beams.

[top]Balconies and atria

Balconies may be attached to modules in various ways:

- Balconies supported by a self-standing steel structure that is ground supported

- Balconies attached between adjacent modules

- Balconies that are attached to corner posts in the modules

- Integrated balconies within an open-sided module.

Atria may be created by attaching a lightweight steel roof to the upper modules or by by spanning the roof between the modules as shown.

[top]Key technical issues

The following general design issues are reviewed below:

- Dimensional planning

- Stability and structural integrity

- Service interfaces

- Acoustic performance

- Fire safety.

[top]Dimensional planning

The factors that influence the dimensional planning of modular systems in general building design may be summarised as:

- Cladding requirements, including alignment with external dimensions of cladding

- Planning grid for internal fit out, such as kitchens

- Transportation requirements, including access to the site

- Building form, as influenced by its functionality

- Repeatability in modular manufacture.

Cladding

Brickwork design is based on a standard unit of 225 mm width and 75 mm depth. Therefore, it may be important to design a floor depth to a multiple of 75 mm in order to avoid non standard coursing of bricks.

Other types of cladding, such as clay tiles or metallic finishes, have their own dimensional requirements, but generally they can be designed and manufactured to fit with window dimensions and other features. Many types of lightweight cladding can be pre-attached to the modules, but it is generally necessary to install a cover piece over the joints between the modules on site, to cater for geometrical tolerances and misalignments.

Standardisation of planning grid

Standardisation of the planning grid is important at the scheme design stage, as the planning grid will be controlled by other building components and fitments. A dimensional unit of 300 mm may be adopted as standard for vertical and horizontal dimensions, reducing to 150 mm as a second level for vertical dimensions. External walls are detailed according to the type of cladding, but a 300 mm total wall width may be adopted as a guide for most cladding materials. The actual width will vary between 200 mm for insulated render and board materials to 320 mm for brickwork.

Typical dimensions for planning in modular construction are presented in the table.

| Application | Internal wall height (mm) | Internal module width (mm) | Internal module length (m) | Ceiling-floor zone (typical) (mm) |

|---|---|---|---|---|

| Study bedrooms | 2400 | 2500 – 2700 | 5.4 to 6 | 300 |

| Apartments | 2400 | 3300 – 3600 | 6 to 9 | 450 |

| Hotels | 2400 – 2700 | 3300 – 3600 | 5.4 to 7.5 | 450 |

| Schools | 2700 – 3000 | 3000 – 3600 open-sided | 9 to 12 | 600 |

| Offices | 2700 – 3000 | 3000 – 3600 | 6 to 12 | 600 – 750 |

| Health sector | 2700 – 3000 | 3000 – 3600 open-sided | 9 to 12 | 600 – 750 |

Transportation

Guidance on transportation on major roads is given by the Road Haulage Association, based on the Road Vehicles (Construction and Use) Regulations[2].

The following basic requirements for transportation should be considered when designing the sizes of modular units:

- Modules exceeding 2.9 m external width require 2 days notice to the police

- Modules exceeding 3.5 m width require a driver’s mate and 2 days police notice

- Modules exceeding 4.3 m width require additional speed restrictions and may require police escort.

Stricter limits may be required for local roads, particularly in urban areas. In all cases, the maximum height of the load is 4.95 m for motorway bridges. Standard container vehicles can deliver one large or two smaller units.

Internal walls

Internal walls comprising the walls of adjacent modules may be designed for a standard 300 mm face to face overall width, incorporating the sheathing boards, internal plasterboards and insulation between the C sections. The gap between the walls may be varied, depending on the number and thickness of boards and size of the wall studs.

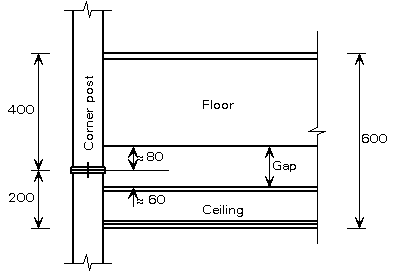

Floor zone

Floors and ceilings in modular construction are deeper than in more traditional construction. The three structural cases of side supported (4-sided modules), corner supported (open-sided) and frame supported modules require different overall ceiling floor dimensions for planning purposes, as follows:

- Continuously supported or 4-sided modules: 300 or 450 mm

- Corner supported or open-sided modules: 450 to 600 mm

- Frame supported modules: 750 to 900 mm.

In most cases, 450 mm may be adopted as a standard for the floor-to-ceiling dimension, although many systems provide shallower depths. For corner supported modules, a standard overall floor and ceiling depth of 600 mm may be used. The gap between the floor and ceiling is a variable depending on the number of boards and the joist size.

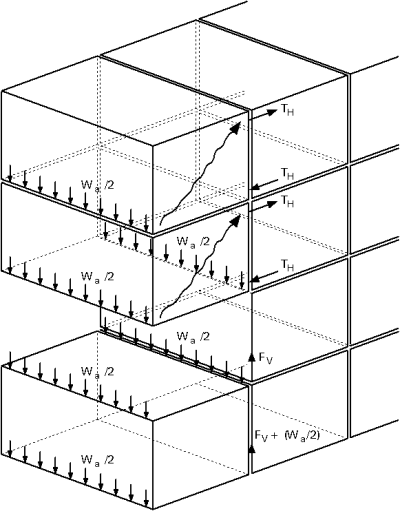

[top]Stability and structural integrity

Overall stability is provided by the modules themselves, or by an external structure. The load path is through the walls of the 3-D units, and so removal of this load path means that the walls should be designed to either:

- Span horizontally over a damaged area by acting as a deep beam ,or

- Be supported by tie forces to the adjacent units.

The latter means that the units should be tied both horizontally and vertically. Robustness is provided by the ties between the modules with a normally assumed minimum tying force equivalent to half the loaded weight of the module (minimum value of 30 kN).

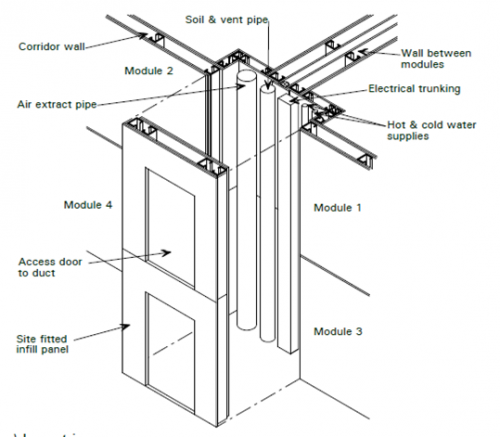

[top]Service interfaces

The installation of electrical, plumbing and heating services in modular buildings can be largely carried out in the factory with final connections made on-site. In traditional construction, such activities are labour intensive on-site and are often on the critical path, so that any difficulties can cause delays. Service strategies that have been used in modular buildings include:

- Use of communal spaces for distribution of services

- Use of the floor or ceiling zone within each module for service distribution

- Installation of services within each module in the factory with site work involving only connection of modules

- Drainage connections of modules connected to vertical risers in the corner of the modules

- Wet areas are connected back-to-back to concentrate service zones.

A vertical service duct is usually incorporated in the corner of each unit to accommodate the vertical drainage and pipework. The services in each module are installed in the factory and terminate in the vertical duct. Access to the service duct is generally only possible from circulation areas outside the modular unit.

The horizontal distribution of services between modules varies, depending on the building type. For most types of residential buildings and hotels, the corridor ceiling and floor voids act as service zones.

Vertical drainage stacks are also installed in the factory and a removable floor panel is provided to allow the final connection to the drains installed in the ground on-site. This requires a high degree of accuracy in setting out service inlets on-site.

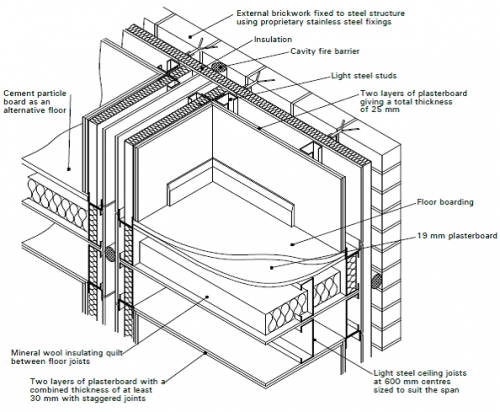

[top]Acoustic performance

Modular construction provides a high level of acoustic separation because each module has separate floor, ceiling and wall elements, which prevents direct transfer of sound along the members.

Modular unit manufacturers use various methods to further improve sound reduction between units – two overlapping layers of plasterboard fixed inside each module, oriented strand board (OSB) or plasterboard fixed as external sheeting or quilt insulation between steel members.

Special care needs to be taken around openings for service pipes or other penetrations, because sound attenuation is particularly affected by air pathways between spaces. Electrical sockets penetrate the plasterboard layer, so they should be carefully insulated using quilt at their rear.

[top]Fire safety

Fire safety is related to provision of adequate means of escape, to ensuring structural integrity, and controlling spread of fire across compartment boundaries. In England, minimum periods of fire resistance are given in Approved Document B[3].

Modular construction generally achieves these requirements by the use of fire resistant plasterboard conforming to BS EN 520[4], Type F. Alternative materials, such as cement particle board and gypsum fibre board may also be used in combination with plasterboard as the facing layer.

Each module is lined internally with one or two layers of fire resistant plasterboard as follows:

- For walls: 30 minutes fire resistance is achieved by a single layer of 12.5 mm fire resistant plasterboard on each face of a steel stud wall

- For walls: 60 minutes fire resistance is achieved by one layer of 12.5 mm fire resistant plasterboard on a layer of 12.5 mm wallboard with staggered joints on each face of a steel stud wall

- For floors: 30 minutes fire resistance is achieved with 18 mm tongue and groove boarding on light steel joists and 12.5 mm fire resistant plasterboard beneath with joints taped and filled

- For floors: 60 minutes fire resistance is achieved with at least 18 mm T&G board floor finish and one layer of 12.5 mm fire resistant plasterboard on a layer of 12.5 mm wallboard with staggered joints beneath the steel joists.

In residential construction, each dwelling usually forms a separate fire compartment. All walls and floors that provide a separating function between compartments require 60 minutes fire resistance. In hotels and other residential buildings, each bedroom may form its own compartment.

In general, a compartment floor will also act as a separating floor for acoustic purposes, as the same measures will also achieve excellent acoustic insulation between rooms.

The inherent separation between modules provides an effective barrier to spread of fire. Means of escape should be considered early in the scheme design in order to ensure that the module design and layout can satisfy these requirements. Cavity barriers are required within the cavity in the external wall between the module and the cladding at intersections with compartment walls. They are also required horizontally at junctions with floors and roof, and vertically at a maximum lateral spacing of 20 m (or 10 m where the material exposed to the cavity is not Class C-s3, d2 or better as defined by Approved Document B[3]). Fire stops must be provided around any penetrations through fire resisting walls.

[top]Sustainability

The concept of using sustainability indicators is becoming accepted as part of the environmental assessment of building construction. For modular construction, it is appropriate to include whole life measures, such as potential re-use, or re-location which are not properly reflected in conventional measures of sustainability.

The sustainability indicators relevant to modular construction are listed below. Comments on how modular construction contributes to these indicators are given against each indicator.

| Sustainability indicator | Comment on modular construction |

|---|---|

| Minimise energy in use | Good level of thermal insulation |

| Efficient heating and cooling systems | |

| Control systems for energy saving provided | |

| Energy saving measures | Efficient manufacture |

| Minimise CO2 production from fossil fuels | Efficient operation and thermal insulation |

| Efficient use of materials | |

| Minimise embodied carbon in materials | Factory controlled operation |

| 100% recyclable | |

| High strength to weight ratio | |

| Ease of deconstruction and reuse |

| Sustainability indicator | Comment on modular construction |

|---|---|

| Suitable site location | Depends on public transport and adjacent public amenities (site specific) |

| Minimise transport impact | Raw materials delivered in bulk to factory |

| Modules delivered to site fitted out | |

| Reduced deliveries to site | |

| Fewer personnel on site |

| Sustainability indicator | Comment on modular construction |

|---|---|

| No use of ozone-depleting substances | Insulation materials selected to suit client needs |

| Minimise waste creation and disposal | Efficient use of materials in factory |

| Minimum / zero waste on site | |

| Recycling of scrap metal | |

| Re-use of modules or components | |

| Maximise waste recycling ratio | Recycled steel used in manufacture |

| Modules can be re-used | |

| Minimise nuisance in construction | Noise, vibration and dust reduced |

| Fast construction process | |

| Less waste disposal | |

| Fewer site deliveries |

| Sustainability indicator | Comment on modular construction |

|---|---|

| Efficient use of materials | Steel has high strength to weight ratio |

| Efficient design in materials use | |

| Long design life | |

| Ability to be recycled or re-used | High proportion can be recycled |

| Modules can be re-used | |

| Low maintenance | Few ‘call backs’ due to quality of production |

| Accessibility for maintenance is easier | |

| Provision for future adaptability | Ability to extend / modify building |

| Sustainability indicator | Comment on modular construction |

|---|---|

| Maximise site safety | Manufacturing process is safe |

| Safer site operations in modular construction | |

| Considerate construction | Speed of construction on site |

| Minimum noise, disruption etc. | |

| Good acoustic insulation | Good insulation between modules |

| Facades insulated against external noise | |

| Adequate day lighting | Large windows can be provided in modules |

| Worker welfare | Safe and clean manufacture and construction |

| Good operational conditions |

[top]Procurement

The typical procurement process for modular buildings requires that the client, designer and manufacturer work together at all phases of the project to maximise the benefits of the off-site process and manufacturing efficiency.

[top]Decision-making process

The decision-making process for modular construction differs from more traditional methods of construction because of:

- The close involvement of the client in assessing the business-related benefits provided by the method of construction.

- The direct involvement of the manufacturer in the design, costing and logistics.

- The need to make key decisions early in the procurement process

- The important environmental and site-related benefits that can be achieved

- The effect of transportation logistics on costs and module sizes.

Since the benefits of modular construction are realised through pre-fabrication, the initial design phase, including the space planning and subsequent detailed design, service integration, and co-ordination, are critical.

[top]Procurement process

In modular construction, the procurement process involves the specialist manufacturers. There are several ways of procuring modular buildings:

- Traditional, in which an architect provides the design co-ordination and the general contractor provides the construction co-ordination. The module manufacturer acts as a specialist sub-contractor.

- 'Design and Build’ process, in which the module manufacturer provides the detailed design and is responsible for construction. In this case, the client’s architect may carry out some of the outline design, and may be novated by the client to work for the contractor.

A Design and Build contract is often used for modular construction. In such cases, the role of the client’s architect will depend on the particular procurement process.

Two methods of specification by the architect are most commonly used:

- The architect may specify the manufacturer who will undertake the detailed design work. This will enable the parties to work together from inception to completion.

- Alternatively, the architect may draft a performance specification for the work. This is then used as a basis for tendering, either through a main contractor or directly to the modular specialists.

It should be recognised that each manufacturer undertakes the construction of their modular units differently and they will be prepared to offer advice and provide drawings at the concept stage.

Importantly, the ‘lead-in’ time required for prototype, design and manufacture of bespoke module units should be considered, although detailed design of the modular units can be carried out in parallel with other design activities. If the module configuration is repeated from other projects, then design time is much reduced.

[top]Typical details

[top]Connections

Guidance on the design and detailing of the most common connection types is given in BS EN 1993-1-8[5]. Manufacturers use the method which best suits their manufacturing process and for which appropriate test data are available.

Structural connections between modules are required for integrity and robustness but details vary depending on the form of the module and the particular application. Floor boarding, plasterboard and sheathing boards are attached using self drilling, self-tapping screws. Manufacturers of light steel framed modules have prepared their own details of horizontal attachments that satisfy robustness requirements.

Attachment points

Attachments between modules are made in both horizontal and vertical directions, primarily to transfer in-plane forces, but also for structured integrity.

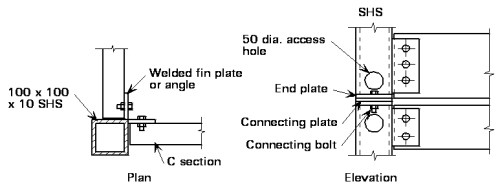

SHS provide a higher compressive resistance than angle profiles and may be used as the corner posts for open sided modules. However, although these sections are compact, their connections can be more complex. A welded fin plate to which the edge beams are bolted is shown. Access holes in the SHS allow bolts to be inserted through end plates to provide for vertical and horizontal attachments.

[top]Facades and interfaces

Various interfaces between modular units and other components in the building may not be under the control of the modular manufacturer. The responsibility for design and coordination usually lies with the building designer.

[top]Foundation interfaces

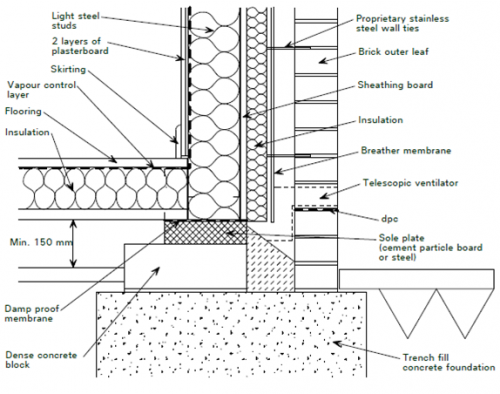

A variety of foundations can be used, including strip, trench-fill, pad and piled foundations. Further information on pile foundations is given in SCI P299. Strip or trench-fill foundations are most common.

Modular units are lightweight and therefore foundations may be smaller than in traditional construction. Nevertheless, the cladding options and building height may dictate the foundation design. With strips, rafts or ground beams, the modular units can be designed to be continuously supported around the perimeter of each unit.

The levelling of the foundations or ground beams is crucial to the subsequent installation and alignment of the modular units. The modular manufacturers have developed their own proprietary locating and fixing mechanisms to aid the positioning of units on the foundations

[top]Wall cladding interfaces

Claddings for modular buildings can be self supporting vertically and only supported laterally by the units. Alternatively, they can be supported entirely by the modular structure.

Two generic systems of facade construction may be considered:

- Cladding that is placed entirely on-site using conventional techniques.

- Cladding that is completely or partially attached in the factory; infill pieces or secondary cladding may be fixed on site.

Cavity barriers must also be incorporated into any cavity that occurs between the external cladding and the modular structure. These must resist the spread of smoke and flame and are required between all separate dwellings or fire compartments. Mineral wool is generally used.

[top]Roofing interfaces

Roofing materials for modular buildings generally comprise tiles supported on battens, or roof sheeting on purlins. Modern roofs may comprise tiles supported on roof sheeting or structural liner trays. Flat roofs can also be constructed with a variety of weatherproof finishes. Insulation in the line of the roof pitch is used where a ‘warm roof’ is created. However, in most cases, the roof space is ‘cold’, and insulation is placed directly on the upper surface of the modular units.

Roofs are generally designed as separate structures that are supported either continuously by the internal walls of the modular units, or as free spanning roofs between the outer walls. Roofs may also be designed as modular units for habitable space, and ease of installation, especially in taller buildings. However, conventional trussed rafter or purlin roofs are mostly used.

Roofs are designed to support the weight of the roof covering, snow loads, services and tanks stored on the roof space, and occupancy loads from habitable use. The interface between the roof and the modular units is designed to resist both compression and tension due to wind uplift. In some cases, the roof can be designed to be detachable so that the building can be extended later. Shallow pitch roofs can be designed to be supported directly by the modular units and are easily dismantled.

[top]References

- ↑ BS EN 10346:2015 Continuously hot-dip coated steel flat products. Technical delivery conditions. BSI

- ↑ Road Vehicles (Construction and Use) Regulations, TSO, 1986 (amended 2018)

- ↑ 3.0 3.1 Approved Document B (Fire safety, Volume 2 – Buildings other than Dwellings), 2019 edition incorporating 2020 amendments – for use in England . Ministry of Housing, Communities & Local Government

- ↑ BS EN 520:2004+A1:2009 Gypsum plasterboards. Definitions, requirements and test methods. BSI

- ↑ BS EN 1993-1-8:2005 Eurocode 3. Design of steel structures. Design of joints. BSI

[top]Resources

- SCI P129 Building design using cold formed steel sections: Fire protection

- SCI P299 Mini-Piles and Composite Ground Floors for Housing

- SCI P302 Modular Construction using Light Steel Framing. Design of Residential Buildings

- SCI P272 Modular Construction using Light Steel Framing. An Architect’s Guide

- SCI P284 Modular Construction in Building Extensions

- SCI P348 Building Design Using Modules

- SCI P367 Energy efficient housing using light steel framing.

[top]See also

- Infill walling

- Residential/Mixed-use Buildings

- Education buildings

- Healthcare buildings

- Robustness

- Acoustics

- Sustainability