Integration of elements for acoustic performance

This article addresses the integration of building elements into separating walls and separating floors without impairing their acoustic performance. The building elements considered are structural, (e.g. hot-rolled columns, and non structural, e.g. building services. When integrating elements, it is important to follow the principles of isolation and sealing for acoustic detailing.

[top]Integration of structural elements

[top]Columns

The integration of columns into infill separating walls is the most common situation where structural elements need to be considered.

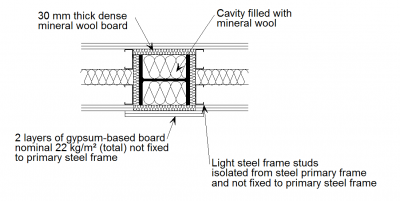

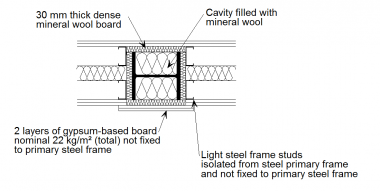

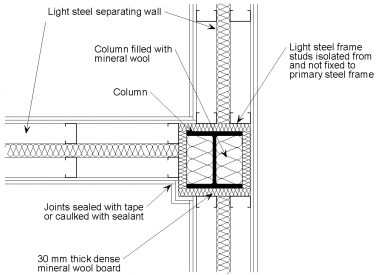

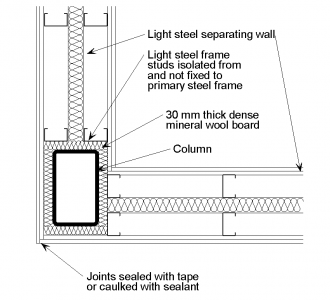

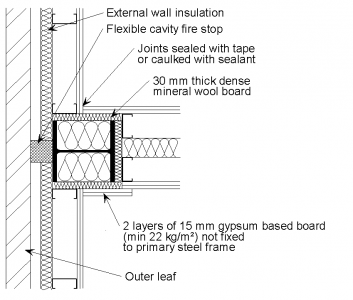

Any columns that are on the line of the separating wall must be integrated so they do not act as a bridge through the wall for sound transmission. It is important to ensure that the gypsum lining is not fixed directly to the columns, and to provide some resilience between the column and the separating wall structure. This is usually achieved by providing 30 mm of dense mineral wool board around the column. The following figures show examples of suitable details.

- Column details

Typical details integrating columns into solid masonry and cavity masonry walls are provided in the SCI Advisory Desk note AD287.

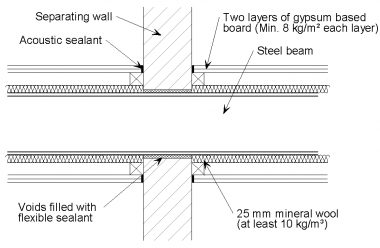

[top]Beams

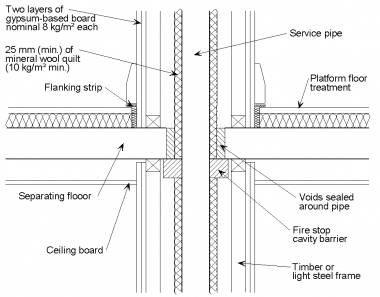

Beams that pass through separating walls should be isolated from the rooms with 25 mm of mineral wool (at least 10 kg/m3) and two layers of gypsum-based boards (at least 8 kg/m2 each layer). Any voids between the beam and the separating walls should be filled with flexible acoustic sealant (see the following figure).

See also details for incorporating beams into composite separating floors.

[top]Integration of services

Services that penetrate separating walls or floors or are located within separating walls or floors must be detailed appropriately to ensure that the acoustic performance of the separating construction is not impaired.

The following aspects should be considered:

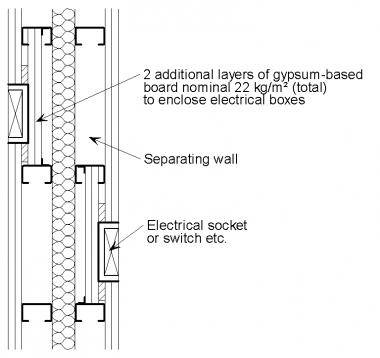

- The location of electrical and piped services in separating walls should be carefully considered, if possible, they should be avoided.

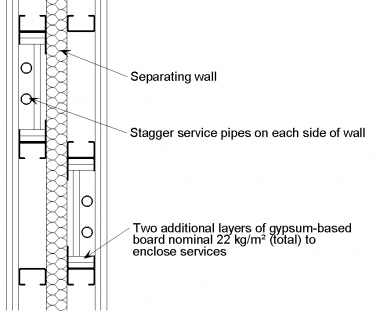

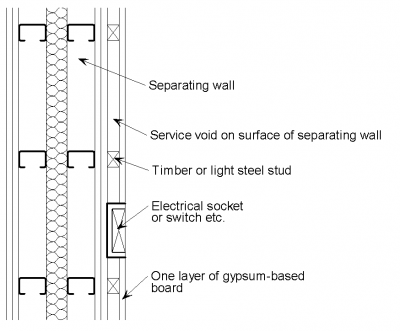

- Where services in separating walls cannot be avoided they should be staggered on either side of a separating wall and should be backed by two layers of gypsum-based board and mineral wool (see following figures).

- Services in separating walls

- Where there are several services to be located in close proximity, e.g. in a kitchen, creating a service void is the preferred method for ensuring that the acoustic performance is not impaired (see below).

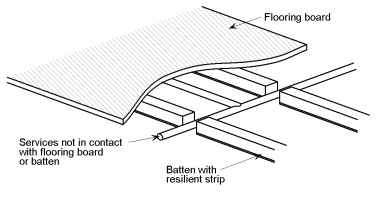

- Services in a separating floor can be accommodated within battened floor treatments but the services should not bridge the resilient foam strip (see below left).

- Services that penetrate a separating floor should be boxed in using two layers of gypsum-based board (at least 8 kg/m2 each layer) and 25 mm of mineral wool (at least 10 kg/m3). Any voids between the beam and the separating walls should be filled with flexible acoustic sealant (see below right).

[top]Down lighters and recessed lighting

Down lighters or recessed lighting may be installed in the ceilings of separating floors with composite decks or precast unit floors with no significant loss of acoustic performance, provided that:

- There is a minimum ceiling void of 75 mm

- Lighting is installed in accordance with the manufacturer’s instructions

- There is no more than one light per 2 m2 of ceiling area in each room

- The centres between lights are not less than 0.75 m

- The openings do not exceeding 100 mm diameter or 100 × 100 mm.

Down lighters or recessed lighting may be installed in the ceilings of light steel separating floors with no significant loss of acoustic performance, provided that:

- The down lighters are backed by two layers of gypsum-based board at least 23 kg/m2, or proprietary acoustic hoods can be applied to down lighters.

- Alternatively, laboratory acoustic testing can be conducted to determine the impact of down lighters on the acoustic performance of the separating floor system. The impact of the down lighter on the acoustic performance of the floor will be product-specific.

When down lighters or recessed lighting are installed, particular attention should be paid to Building Regulations Part B (Fire Safety). Some down lighters are available with integral acoustic (and fire) resistance; or proprietary acoustic covers are available.

[top]Further reading

- Carl Hopkins. Sound insulation. Elsevier, Butterworth-Heinemann, 2007.

- M.W. Simons & J. R. Waters. Sound Control in Buildings. A guide to Part E of the Building Regulations. Blackwell publishing, 2004.

- BS EN ISO 10140: 2010 Acoustics. Laboratory measurement of sound insulation of building elements. Various parts. British Standards Institution.

- BS EN ISO 717: 2013 Acoustics. Rating of sound insulation in buildings and of building elements. Various parts. British Standards Institution.

- Robust Details Handbook, Robust Details Limited

[top]Resources

- SCI P372 Acoustic Detailing for Steel Construction

- SCI P320 Acoustic performance of light steel framed systems

- SCI P322 Acoustic performance of composite floors

- SCI P336 Acoustic detailing for multi-storey residential buildings

- SCI P371 Acoustic performance – Case Studies

- SCI Advisory Desk note AD287. Acoustic detailing: steel columns in masonry separating walls.

- SCI Acoustic performance prediction tool for separating floors and walls

[top]See also

- Introduction to acoustics

- Acoustic regulations

- Acoustic performance of walls

- Acoustic performance of floors

- Junction details for acoustic performance