Difference between revisions of "Newark Dyke"

| Line 1: | Line 1: | ||

{{#image_template:image=File:Newark_Dyke.jpg|caption= |align=right|wrap=true|width=500}} | {{#image_template:image=File:Newark_Dyke.jpg|caption= |align=right|wrap=true|width=500}} | ||

| − | This railway bridge comprises a 77m span bowstring truss which replaced two 1890 steel truss decks that were unable to cope with the planned increase in line speed. Nevertheless, the old steel truss decks had stood the test of time, and the replacement scheme included their removal for [[Recycling and reuse|recycling]] into new steel products. | + | This railway bridge comprises a 77m span bowstring [[Bridges#Truss bridges|truss]] which replaced two 1890 steel truss decks that were unable to cope with the planned increase in line speed. Nevertheless, the old steel truss decks had stood the test of time, and the replacement scheme included their removal for [[Recycling and reuse|recycling]] into new steel products. |

Steel was selected for the new bridge because of its high strength to weight ratio, which permitted a shallow construction depth and minimised the total weight to be slid into position. The low self-weight also minimised foundation works adjacent to the existing rail line. This bridge was the first UK [[Bridges|steel bridge]] to be designed for the next generation of 225 Km/hr trains, and was completed late in 2000. | Steel was selected for the new bridge because of its high strength to weight ratio, which permitted a shallow construction depth and minimised the total weight to be slid into position. The low self-weight also minimised foundation works adjacent to the existing rail line. This bridge was the first UK [[Bridges|steel bridge]] to be designed for the next generation of 225 Km/hr trains, and was completed late in 2000. | ||

Revision as of 11:59, 12 March 2019

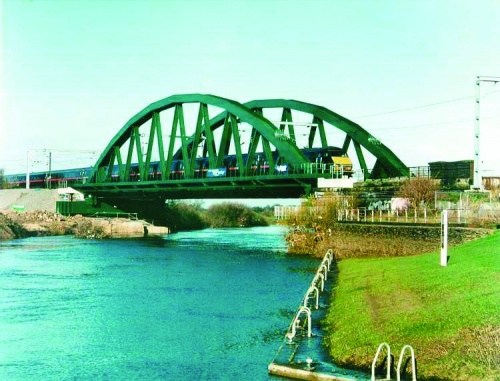

This railway bridge comprises a 77m span bowstring truss which replaced two 1890 steel truss decks that were unable to cope with the planned increase in line speed. Nevertheless, the old steel truss decks had stood the test of time, and the replacement scheme included their removal for recycling into new steel products.

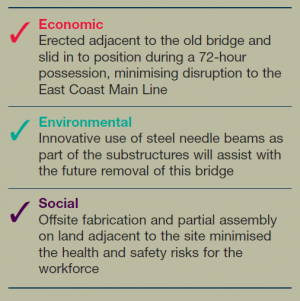

Steel was selected for the new bridge because of its high strength to weight ratio, which permitted a shallow construction depth and minimised the total weight to be slid into position. The low self-weight also minimised foundation works adjacent to the existing rail line. This bridge was the first UK steel bridge to be designed for the next generation of 225 Km/hr trains, and was completed late in 2000.

Structural Engineer - Cass Hayward LLP

Steelwork Contractor - Cleveland Bridge UK Ltd.

Main Contractor - Skanska Construction UK Ltd.

Client - Railtrack plc