Difference between revisions of "External steel at the D Y Patil School of Management"

| (6 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

The school is a 10 storey university faculty building with staff and student accommodation above. | The school is a 10 storey university faculty building with staff and student accommodation above. | ||

*The lower 5 floors are in RC concrete and upper 5 floors are in [[Composite_construction|composite steel construction]] | *The lower 5 floors are in RC concrete and upper 5 floors are in [[Composite_construction|composite steel construction]] | ||

| Line 13: | Line 5: | ||

*[[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|Intumescent coating]] was not considered as an appropriate solution due to the difficulties in getting appropriately skilled local contractors | *[[Fire_protecting_structural_steelwork#Thin_film_intumescent_coatings|Intumescent coating]] was not considered as an appropriate solution due to the difficulties in getting appropriately skilled local contractors | ||

*The solution was to use a [[Structural_fire_engineering|fire safety engineering]] assessment to demonstrate that the exposed steel could be left unprotected. | *The solution was to use a [[Structural_fire_engineering|fire safety engineering]] assessment to demonstrate that the exposed steel could be left unprotected. | ||

| − | <gallery caption="The D.Y. Patil School of Management " widths=400px heights=400px> | + | <br> |

| + | <gallery caption="The D.Y. Patil School of Management " perrow=2 mode=nolines widths=400px heights=400px> | ||

Image:Mumbai_school_1.png| | Image:Mumbai_school_1.png| | ||

Image:Mumbai_school_2.png| | Image:Mumbai_school_2.png| | ||

</gallery> | </gallery> | ||

| + | <br> | ||

The brief was to omit [[Fire_protecting_structural_steelwork| fire protection]] where possible from the exposed structural elements of the residential floors. This steel was in the form of perimeter [[Steel_construction_products#Standard_open_sections |beams]] and hangers, hangers in open circulation spaces and a crown structure. This case study deals with the first of these: the perimeter [[Steel_construction_products#Standard_open_sections |beams]] and hangers. | The brief was to omit [[Fire_protecting_structural_steelwork| fire protection]] where possible from the exposed structural elements of the residential floors. This steel was in the form of perimeter [[Steel_construction_products#Standard_open_sections |beams]] and hangers, hangers in open circulation spaces and a crown structure. This case study deals with the first of these: the perimeter [[Steel_construction_products#Standard_open_sections |beams]] and hangers. | ||

The risk assessment sought to account for the difference in risk as the perimeter steel is exposed to a range of fire loads and also to take into consideration the impacts of [[Sprinklers_in_UK_fire_codes |sprinklers]]. Two scenarios were examined. | The risk assessment sought to account for the difference in risk as the perimeter steel is exposed to a range of fire loads and also to take into consideration the impacts of [[Sprinklers_in_UK_fire_codes |sprinklers]]. Two scenarios were examined. | ||

| − | {{#image_template:image=File:Fractile_table.png|align=left|width= | + | {{#image_template:image=File:Fractile_table.png|align=left|width=600}} |

The external steelwork approach given in the [[Design_using_structural_fire_standards#Fire_Eurocodes|fire Eurocodes]]<ref name="No1"> BS EN 1991-1-2: 2002, Eurocode 1. Actions on Structures. General actions. Actions on structures exposed to fire. BSI</ref> was used. | The external steelwork approach given in the [[Design_using_structural_fire_standards#Fire_Eurocodes|fire Eurocodes]]<ref name="No1"> BS EN 1991-1-2: 2002, Eurocode 1. Actions on Structures. General actions. Actions on structures exposed to fire. BSI</ref> was used. | ||

*Define fire scenarios for compartment and localised fires. | *Define fire scenarios for compartment and localised fires. | ||

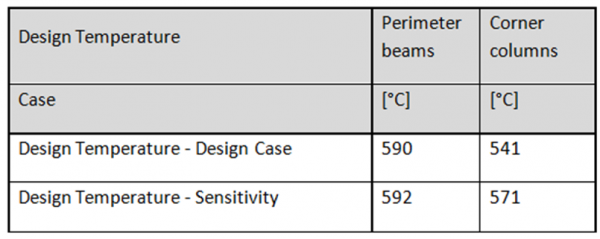

*Determine flame shape (non-through draft, through draft and wind conditions) | *Determine flame shape (non-through draft, through draft and wind conditions) | ||

| − | <gallery | + | <br> |

| + | <gallery perrow=2 widths=400px heights=300px> | ||

Image:Through_draft.png| | Image:Through_draft.png| | ||

Image:Non_through_draft.png| | Image:Non_through_draft.png| | ||

| − | |||

| − | |||

| − | |||

Image:Perimeter_column_deflected_flames.png|Perimeter columns with deflected flames (plan view) | Image:Perimeter_column_deflected_flames.png|Perimeter columns with deflected flames (plan view) | ||

Image:Corner_column_deflected_flames_1.png| Corner columns with deflected flames (plan view) | Image:Corner_column_deflected_flames_1.png| Corner columns with deflected flames (plan view) | ||

</gallery> | </gallery> | ||

| + | <br> | ||

*Calculate steel temperature of external members | *Calculate steel temperature of external members | ||

*Calculate remaining structural capacity in fire and check against the fire limit state loads | *Calculate remaining structural capacity in fire and check against the fire limit state loads | ||

| + | <br> | ||

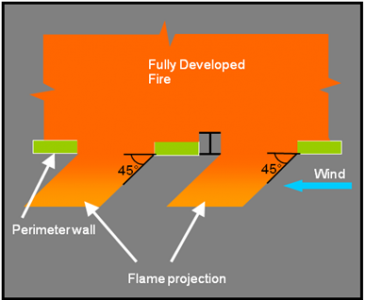

A total of 368 fire scenarios were analysed for the different structural elements, different compartments and different window breakages. The maximum temperatures reached were calculated as: | A total of 368 fire scenarios were analysed for the different structural elements, different compartments and different window breakages. The maximum temperatures reached were calculated as: | ||

{{#image_template:image=File:Design_temperatures.png|align=left|width=600}} | {{#image_template:image=File:Design_temperatures.png|align=left|width=600}} | ||

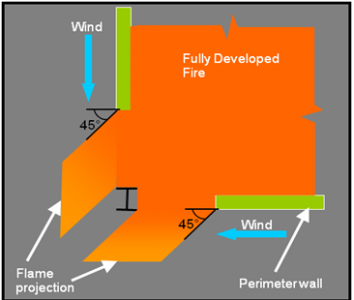

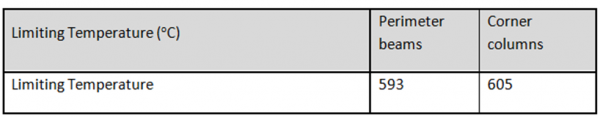

And the failure (limiting) temperatures were calculated as: | And the failure (limiting) temperatures were calculated as: | ||

| − | {{#image_template:image=File:Limiting_temperatures.png|align=left|width= | + | {{#image_template:image=File:Limiting_temperatures.png|align=left|width=600}} |

FEDRA concluded that the exposed faces of the vast majority of the perimeter elements could be unprotected if they were protected as shown. | FEDRA concluded that the exposed faces of the vast majority of the perimeter elements could be unprotected if they were protected as shown. | ||

| − | {{#image_template:image=File:Exposed_faces.png|align=left|width=400} | + | {{#image_template:image=File:Exposed_faces.png|align=left|width=600}} |

| + | |||

| + | {|class="wikitable" width=400 | ||

| + | |- | ||

| + | |'''Architect'''||Foster + Partners | ||

| + | |- | ||

| + | |'''Fire Engineer'''|| Buro Happold FEDRA | ||

| + | |- | ||

| + | |'''Client'''||D.Y. Patil | ||

| + | |} | ||

| + | |||

==References== | ==References== | ||

<references/> | <references/> | ||

| + | |||

| + | [[Category:Case studies - Structural fire engineering]] | ||

Latest revision as of 12:18, 12 March 2019

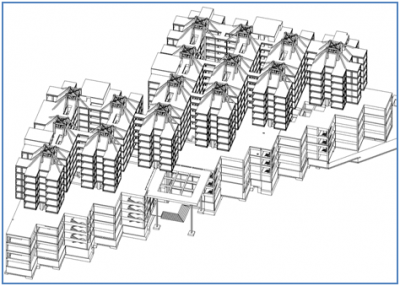

The school is a 10 storey university faculty building with staff and student accommodation above.

- The lower 5 floors are in RC concrete and upper 5 floors are in composite steel construction

- The upper levels are supported by full height Vierendeel frames and by hangers from a ‘crown structure’.

- The client required the steel structure to be expressed

- Intumescent coating was not considered as an appropriate solution due to the difficulties in getting appropriately skilled local contractors

- The solution was to use a fire safety engineering assessment to demonstrate that the exposed steel could be left unprotected.

- The D.Y. Patil School of Management

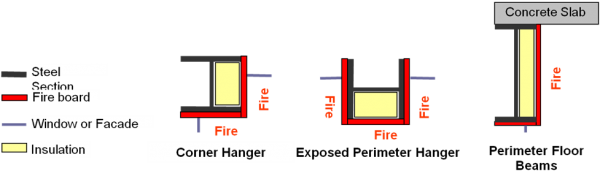

The brief was to omit fire protection where possible from the exposed structural elements of the residential floors. This steel was in the form of perimeter beams and hangers, hangers in open circulation spaces and a crown structure. This case study deals with the first of these: the perimeter beams and hangers.

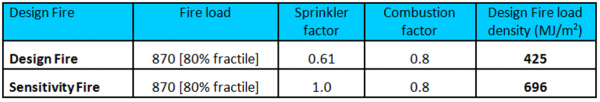

The risk assessment sought to account for the difference in risk as the perimeter steel is exposed to a range of fire loads and also to take into consideration the impacts of sprinklers. Two scenarios were examined.

The external steelwork approach given in the fire Eurocodes[1] was used.

- Define fire scenarios for compartment and localised fires.

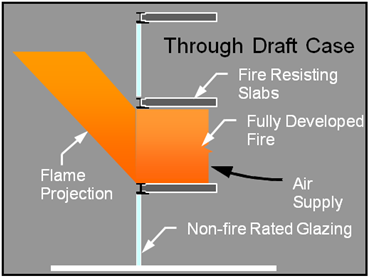

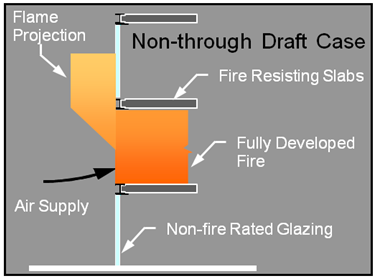

- Determine flame shape (non-through draft, through draft and wind conditions)

- Calculate steel temperature of external members

- Calculate remaining structural capacity in fire and check against the fire limit state loads

A total of 368 fire scenarios were analysed for the different structural elements, different compartments and different window breakages. The maximum temperatures reached were calculated as:

And the failure (limiting) temperatures were calculated as:

FEDRA concluded that the exposed faces of the vast majority of the perimeter elements could be unprotected if they were protected as shown.

| Architect | Foster + Partners |

| Fire Engineer | Buro Happold FEDRA |

| Client | D.Y. Patil |

References

- ↑ BS EN 1991-1-2: 2002, Eurocode 1. Actions on Structures. General actions. Actions on structures exposed to fire. BSI