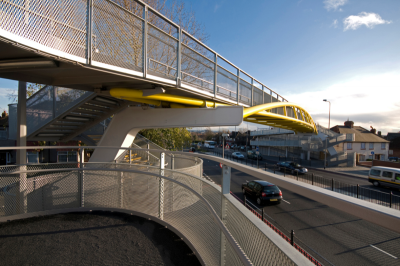

A40 Perryn Road Footbridge

Structural Steel Design Awards 2010 - Commendation

Perryn Road Footbridge is a high quality steel bridge designed to fit a highly constrained site and to meet challenging accessibility requirements. The bridge layout and architecture required careful consideration to successfully create a crossing that is attractive, safe to use and serves the needs of the local community and the client.

Land availability was severely restricted and compounded by numerous buried services that ran under the footway. Construction of the footbridge had to be undertaken within the constraints of the main contract with regard to working areas, working times and lane closures. The footbridge design allowed construction to satisfy the many conflicting and pre-existing constraints and was programmed to minimise disruption.

The architecture provides a clearly understandable link through the “spiralling ribbon” formed by the stairs, ramps and main span parapets. The choice of finishes, architectural lines and structural arrangements successfully integrate the different elements of the crossing. The bridge supports cantilever over the footways with unique asymmetrical spiral staircases winding around and cantilevering from the supports. The ramps are as compact as possible, yet have a maximum gradient of 1:12 and regular landings. Expanded steel mesh screens on the ramps allow good visibility for users and protect the privacy of nearby houses. Both stairs and ramps were provided to cater for all users, and the arrangement allows common entry points for all, and features a bespoke lighting scheme to maximise the security of users.

The bridge supports are major steel fabrications having numerous functions but nonetheless are elegant structural elements. The main span and supports are fully integral, with full moment connections between the truss and supports. To ensure the safety of the crossing the supports were required to withstand the onerous requirements of full collision loading. Dynamic analysis revealed that the supports were important factors in the bridge harmonics. To provide the necessary stiffness and mass, but retain a slender profile, the supports were fabricated in 40mm steel plate and then concrete filled. The only viable foundation locations were extremely restricted areas off the back of footpath. Whilst increasing the main span, these locations avoided costs and risks of delays associated with significant service diversions. To utilise the available foundation areas the bridge supports were required to cantilever off concrete plinths/pilecaps well away from the carriageway. Large mechanical connections, utilising machined shear plates, dowels and high tensile bars, connect the bridge supports to the foundations and transmit significant ultimate limit state loads into the foundations.

The bridge truss comprises curved upper and lower chords that are connected by variously sloping straight bracing members. All the chords and bracing are circular hollow sections, and the sizing and truss geometry was carefully developed such that no stiffening or overlapping of members is required at joint nodes. The chord members are curved to parabolas, the top chords being in vertical planes whilst the bottom chords are in inclined planes to give the bridge deck an elegant vertical profile. Further subtleties to the truss design are that the cross frames are skewed to match the bridge supports; there are elements of symmetry in the truss; and the bottom chord returns in an elegant loop supporting short back spans and the top of the stairs. The structural arrangement of this integral bridge allows a shallow span/depth ratio such that the truss does not rise above the parapets. The bridge deck and guardrails form a continuous ribbon with the link spans, cradled within but distinct from the open tubular steel structure.

The bridge was transported to site, painted and erected as one unit. the bridge supports were erected and concrete filled. During a single night-time road closure, the first permitted on the A40, the lightweight main span was lifted into position and made fully integral with the supports, which had been concrete filled, using bolted connections. Construction of the stairs, ramps and footway works then continued and the bridge was partially opened in June 2009. The footbridge was fully opened in October 2009.

| Architect | Grimshaw |

| Structural Engineer | Hyder Consulting (UK) Ltd. |

| Steelwork Contractor | S H Structures Ltd. |

| Main Contractor | Carillion Civil Engineering |

| Client | Transport for London |

Judges' comments

Steelwork is used imaginatively in this high quality scheme for a very constrained and challenging site in a residential area.

Crossing one of London’s busiest arteries, the skewed deck on cantilevered supports, with spiral staircases and compact stacked ramps, provides access for all types of users.

A well considered and executed urban design produces a robust yet elegant solution.