Difference between revisions of "The case for steel"

| Line 35: | Line 35: | ||

*To help small to medium sized steelwork contractors, a health and safety advisory service called Safety in Steel Construction (SiSC) has been launched, giving BCSA members access to direct and regular monitoring and advice. | *To help small to medium sized steelwork contractors, a health and safety advisory service called Safety in Steel Construction (SiSC) has been launched, giving BCSA members access to direct and regular monitoring and advice. | ||

*The BCSA has introduced the [[Media:BCSA_SSHC.pdf|Safe Site Handover Certificate (SSHC)]], which has improved communication between all parties involved and acts as a monitoring aid during the programme of works, covering site conditions and [[Construction#Steel_erection|steel erection]], ensuring that site risks are minimised. | *The BCSA has introduced the [[Media:BCSA_SSHC.pdf|Safe Site Handover Certificate (SSHC)]], which has improved communication between all parties involved and acts as a monitoring aid during the programme of works, covering site conditions and [[Construction#Steel_erection|steel erection]], ensuring that site risks are minimised. | ||

| − | *The [[Fabrication#Steel_Construction_Certification_Scheme|Steel Construction Certification Scheme (SCCS)]] is [ | + | *The [[Fabrication#Steel_Construction_Certification_Scheme|Steel Construction Certification Scheme (SCCS)]] is [https://www.ukas.com/ UKAS] accredited, offering management systems certification services specifically tailored for the steel industry. A wide range of audits are carried out on quality, environmental, safety management and factory production control systems. |

<br> | <br> | ||

{{#image_template:image=File:Edge_protection.jpg|caption=Pre-attached edge protection during [[Construction#Steel_erection|erection]]|align=left|wrap=true|width=400}} | {{#image_template:image=File:Edge_protection.jpg|caption=Pre-attached edge protection during [[Construction#Steel_erection|erection]]|align=left|wrap=true|width=400}} | ||

Revision as of 12:57, 22 August 2022

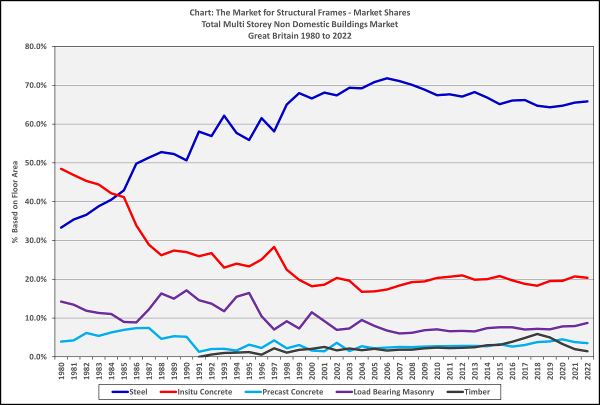

The advantages that steel offers to the construction sector have long been recognised by designers and specifiers. This is demonstrated by steel's market share which, over the past 20 years, has consistently been over 90% for single-storey industrial buildings and 65% for multi-storey non-residential buildings.

The versatility of steel gives architects the freedom to achieve their most ambitious visions. Structural steel is an essential component of most stadia, shopping centres and commercial developments; steel cladding systems adorn iconic, landmark structures worldwide. Steel is one of the most sustainable construction materials. Its strength and durability coupled to its ability to be recycled, again and again, without ever losing quality make it truly compatible with long term sustainable development. Building owners value the flexibility of steel buildings, and the value benefits they provide, such as the light, open, airy spaces that can be created, making it ideal for modernisation, reconfiguring, extending or adapting with minimal disruption, and without costly and sometimes harmful demolition and redevelopment. Even without these benefits, steel is often the first choice on the basis of cost alone. Many of the advantages of steel construction are applicable to all building types and sectors. In this article the case is made for steel construction in nine key areas.

[top]Health and safety

Health and safety is a key business driver in construction. Offsite fabrication of components and rapid on-site assembly by skilled personnel make steel an inherently safe construction material. Industry surveys consistently demonstrate that steel is the safest material choice. Here we highlight the fundamental H&S safety benefits of steel construction and demonstrate how the sector ensures that these benefits are delivered.

[top]Erected by skilled specialists

Steelwork contractors are highly skilled specialists, trained in a single discipline. They must hold industry recognised qualifications in the design, fabrication and erection of steel-framed structures. That means the steel elements are quickly and accurately assembled on site following proven, reliable and safe techniques. What’s more, unlike concrete, steel frames are full strength as soon as they are completed, enabling stairs to be fitted and providing safe access to the structure for other trades straight away. Steel decking for composite slabs also provides a safe platform after installation, as well as protection to lower storeys.

A number of innovative approaches to safe erection are now in common use on site. These include:

- Dedicated lifting points on members and lifting brackets

- Support frames that allow mobile elevating working platforms (MEWPs) to be used on erected steelwork

- Edge protection attached at ground level prior to erection

- The widespread use of nets for following trades

- Offsite cutting of composite floor decking.

[top]Rapid, waste-free assembly

All steel structural elements can be very precisely fabricated to tight tolerances before delivery to site, facilitating rapid and waste-free assembly. From the very beginning, specialist designers work with the construction team to ensure that the steel frame design can be manufactured and erected safely. Erection procedures can be planned in detail using 3D models and, for the most complex structures, trial assemblies can be staged to ensure everyone understands the required procedure.

[top]Offsite fabrication for precision parts

Fabrication of the individual steel elements takes place offsite under controlled, highly regulated and safe factory conditions where the use of leading edge fabrication systems delivers precision-engineered components. With so much work carried out offsite, the on site construction programme is reduced and the build programme is relatively unaffected by adverse weather conditions. Furthermore, steel components can be pre-assembled or fabricated into modules either offsite or at low level, which reduces the need for working at height. Steel can be delivered to site as and when it is required, reducing the need for potentially hazardous on site storage.

[top]Sector H&S assurance

The steel construction sector has put in place a number of measures to ensure its continued excellent H&S track record. These include:

- To help small to medium sized steelwork contractors, a health and safety advisory service called Safety in Steel Construction (SiSC) has been launched, giving BCSA members access to direct and regular monitoring and advice.

- The BCSA has introduced the Safe Site Handover Certificate (SSHC), which has improved communication between all parties involved and acts as a monitoring aid during the programme of works, covering site conditions and steel erection, ensuring that site risks are minimised.

- The Steel Construction Certification Scheme (SCCS) is UKAS accredited, offering management systems certification services specifically tailored for the steel industry. A wide range of audits are carried out on quality, environmental, safety management and factory production control systems.

When selecting steelwork contractors for tender lists there is no easier way of prequalifying companies than using the membership list of the British Constructional Steelwork Association (BCSA), or The Register of Qualified Steelwork Contractors Scheme for Bridgeworks (RQSC). With over 100 steelwork contractors on them, the lists can be used to select a steelwork contractor who has the special skills to suit your project. BCSA’s experienced professional assessors visit all companies to assess their capabilities in 14 categories of building steelwork and 11 subcategories of bridge construction. From that profile it is possible to match the tender list to the particular demands of a particular project. The lists also classify companies by suggesting a maximum contract value that they should handle.

[top]Vibration and acoustics

Steel-framed buildings have a track record of meeting strict vibration and acoustic performance criteria for the most demanding applications.

[top]Vibration performance

For most normal office buildings, straightforward steel construction systems will meet the required vibration performance criteria without modification. For more vibration sensitive applications, such as hospital operating theatre floors, steel’s advantages can be captured with additional stiffening applied to the steel frame if required to meet acceptability criteria. Even with these additions, steel remains the most cost-effective and lightweight solution. Advanced analysis approaches are available to account for specific structural layouts, architectural arrangements such as corridor arrangements, degree of fit-out and location of partitions. These approaches have been successfully calibrated against on-site tests.

Long-span applications, for which steel is the only option, have been found to offer excellent vibration damping, despite common preconceptions (see SCI P354). The greater mass of the long span sections which participate in any motion reduces the magnitude of the vibration response. The steel sector has extensive experience in designing steel structures to ensure compliance with even the strictest vibration performance criteria. The National Health Service (NHS) in the UK demands some of the world’s most exacting vibration standards for its operating theatre floors. Detailed studies have shown that steel-framed buildings provide floors with vibration performance that meets or exceeds these stringent specifications, while still achieving the cost and flexibility criteria essential for the UK’s healthcare investment programmes.

[top]Acoustic performance

Steel-framed buildings can comfortably satisfy the acoustic performance requirements for residential buildings, as set out in Approved Document E[1]. As with any framing material, including concrete, careful detailing is needed for floor finishes, walls, service penetrations and flanking. Robust Details are available for these elements, providing proven and reliable acoustic performance. Details are available for:

- Light steel framing systems

- Composite floors

Acoustic details in SCI guidance (e.g. P372) are available for:

- Light steel framing systems, including infill walls

- Composite floors

- Steel columns in blockwork walls

For external walls, where both acoustic and thermal insulation must be provided, infill steel-framed construction is the perfect solution. Insulation is provided within the frame, giving excellent thermal properties. In addition, infill solutions provide a robust wall with no gaps between the wall and main structure, which can be a problem with blockwork walls.

[top]Sustainability

Steel is the leading construction material for sustainability, offering exceptional environmental, social and economic benefits. The balance between the three elements sees steel deliver a sound sustainability case and contribute to the circular economy.

[top]Environmental benefits

Steel can be multicycled endlessly with no detrimental effect on its properties. When a steel-framed building is demolished, its components can be reused or returned to the steelmaking process to create brand new components. In the UK, 96% of steel construction components are recovered in this way. Globally, recycled steel accounts for 50% of new steel production.

Composite steel floors are given the highest (A+) environmental rating in the BRE’s Green Guide to Specification[2].

Because steel structures are significantly lighter than concrete equivalents, they require less extensive foundations, which reduces the environmental impact of the build. If steel pile foundations are used, these can be extracted and recycled or reused at the end of a building’s life, leaving no waste material on site.

Long-span steel solutions provide flexible clear span spaces that future-proof a building, offering an increased lifetime. Steel structures are durable and can be readily adapted, improving their economic viability as they can easily be updated or modernised.

The steel sector has developed a Sustainability Charter for steelwork contractors. Companies demonstrate their commitment to wide-ranging sustainable practices, and submit to an annual independent review of their commitment to the charter. A growing number of steelwork contractors are assessing (and reducing) their carbon footprint. The sector has developed a tool to assess the carbon emissions of steelwork contractors in a standardised manner and recent studies have enabled an average carbon footprint for steel fabrication to be derived.

A carbon footprint tool for buildings is available.

Many parts of the supply chain, including raw material suppliers, steel manufacturers, steelwork contractors and surface coating manufacturers have ISO 14001[3] environmental management systems accreditation. Also, increasingly, steelwork contractors are getting accreditation to BES 6001[4], the BRE's framework standard for responsible sourcing of construction products.

Many multi-storey buildings are designed with solar shading and active energy creation technologies, such as photovoltaics (PVs), as shown in the Bishop’s Square project in London.

[top]Social benefits

Factory based steelmaking and fabrication supports a stable local workforce, benefiting family life and building stable communities. Offsite fabrication of structural steelwork is one of the safest forms of construction, promoting risk free working practices and allowing investment in developing the skills of the workforce. The impact of steel-based construction on local communities is minimised by the relatively short building programme, minimal site deliveries and the dry, dust-free and comparatively quiet construction process.

[top]Economic benefits

Fabrication in controlled factory conditions results in high quality, defect free components that produce very little waste during the construction process. Furthermore, steel structures are durable and require little maintenance, extracting maximum value from the resources invested in the structure and minimising its whole-life costs. Long span steel sections enable large open plan, column free spaces to be created inside buildings, providing flexible areas that can be set out in an endless variety of configurations. Such ‘future-proofing’ means that the building’s use can be changed and the layout adapted many times – extending the lifetime of the structure. Short construction periods leads to cost savings in site preliminaries, earlier return on investment and reduced interest charges. Time related savings can easily amount to 3-5% of the overall project value, reducing the client’s requirements for working capital and improving cash flow.

[top]Fire performance

The response of steel structures to fire is well understood, and extensive best-practice guidance is available. The performance of steel components and steel structures in fire has been researched more extensively than any other building material. The steel sector has invested decades of research into understanding the behaviour of structural steel components in fire - giving designers the confidence to engineer buildings safely in steel.

[top]Unrivalled understanding of steel in fire

Extensive testing of individual elements of structural steelwork and complete steel structures has furnished the industry with an unrivalled understanding of the response of steel buildings to fire. This has enabled advanced design and analysis techniques to be developed that allow very precise specification of the fire protection requirements of steel-framed buildings, often resulting in significant reductions in the amount of fire protection required. By comparison, relatively little is known about the performance of concrete structures in fire.

[top]Efficiently engineered for fire resistance

Simple and advanced methods are available for the analysis of composite steel deck floors in fire; these can lead to the elimination of fire protection on many secondary beams. Pre-engineered shallow floor systems can even be designed to achieve a 60-minute fire resistance without additional fire protection.

[top]Fire protection innovations

The UK has an effective fire protection industry. The presence of a large number of manufacturers and applicators ensures that the industry is innovative and efficient. Thin film intumescent coatings are now the most popular form of fire protection in the UK, and a successful offsite application sector using this material has been developed. Offsite application thin film intumescent coatings offers considerable benefits, including:

- Reduced construction times

- Improved site safety

- Speedier access for follow-on trades on site

- Improved quality control

- Reduced weather sensitivity.

Most long span and cellular construction now use the offsite application process.

[top]Quality

Steel offers consistently high quality standards, precision products and guaranteed strength and durability in the most challenging environments. If you’re looking for quality assurance, structural steelwork delivers complete certainty, every time. Steel is produced to the most exacting specifications under highly controlled conditions, eliminating the risks of on site variability. Rigorous quality assurance processes give full traceability at all stages in the supply chain, from steelmaking through fabrication to erection on site.

All structural steel used in the UK is UKCA marked (or CE marked until 31 December 2022), giving assurance that the material is compliant with the Construction Products Regulations[5]. To help customers choose the highest quality contractors, all BCSA Members are assessed each year and categorised according to their technical and financial capabilities. In addition, appropriate conformity assessment compliance is a requirement for all BCSA Members.

[top]Precision-engineered products

The manufacturing process for steel components is driven by advanced 3D modelling and numerically controlled fabrication machinery, resulting in high accuracy offsite and delivering a precision-engineered product. Because of the accuracy of individual components, steelwork is erected to tight tolerances on site. For particularly demanding fabrications, trial assemblies can be arranged to ensure the on site erection runs smoothly. This approach was used for the construction of Heathrow’s Terminal 5.

[top]Strong, ductile and durable

Unlike concrete, erected steelwork does not shrink or creep. Steel is also highly durable. Steel piles extracted from an area with a high water table have been found to be fit for reuse after more than 100 years in the ground. Steel is strong and ductile too, making it highly resistant to accidental damage. If any damage does occur, it can easily be repaired by cutting, welding or bolting to restore its full strength. Steelwork erection on site is not restricted by weather conditions, other than high winds, and can continue year round, with no need for special protection measures in winter.

[top]Economics

Independent studies consistently show that steel is the most cost-effective framing solution for multi-storey construction in the UK market.

[top]Take a load off your foundations

Cost savings in steel buildings start at the foundations, where the loads imposed by a steel frame are up to 50% less than those of a concrete alternative. That means foundations can be much smaller and therefore cost considerably less. Foundations are a major component of overall building costs, so lighter foundation loads can have a big impact on costs. By way of example, the total mass of materials used to construct One Kingdom Street in London was estimated to vary between 32.3mt (steel frame) and 55.4mt (concrete frame); a 72% difference.

[top]Speed of construction

Steel structures can be erected speedily, the predictability and accuracy of steel components speeds up the process and allows follow-on trades to get to work sooner. This deliver time savings in the build programme compared to a concrete frame. In fact, speed of erection is often one of the main criteria for selecting steel. In many inner city projects, it is also important to reduce disruption to nearby buildings and roads. Short construction periods leads to savings in site preliminaries, earlier return on investment and reduced interest charges. Time related savings can easily amount to between 3% and 5% of the overall project value, reducing the client’s requirements for working capital and improving cash flow.

[top]Cost savings in a competitive market

In inflation adjusted terms, steel has fallen in price since 1980 and is cheaper than it was 15 years ago. Huge productivity advances have also been achieved throughout the steel supply chain and the cost saving benefits shared with customers. One of the best guarantees of a competitive price is the large number of steelwork contractors that can tender for projects. A competitive sector ensures that customers get value for money. There are some 100 audited steelwork contractor members of the BCSA, all of which deliver high quality projects that consistently delight their clients.

[top]Long-life durability

Steel-framed structures are highly durable and do not age or decay as quickly as other construction materials, lasting longer before refurbishment is required. Buildings that can be easily adapted, avoid costly and environmentally harmful demolition and redevelopment. Steel’s inherent adaptability and flexibility also means that future changes or extensions – even vertically – can be carried out with minimal disruption and cost.

[top]Flexibility for changing times

Steel-framed buildings are among the most adaptable and flexible assets a business can invest in. The large column free spaces created by long span steel sections mean that buildings can be constantly adapted to cope with the changing requirements of its occupants. Building interiors can be easily and economically adapted, avoiding the high costs of redevelopment or demolition.

[top]Steel construction supply chain

Close collaboration in steel supply chains delivers best value, best practice and assured quality to the construction sector. The UK steel sector has long established, world-class integrated steel supply chains that have a remarkable track record of delivering best value to the construction sector. The relationships between steel manufacturers, steel stockists, bolt and paint manufacturers, software suppliers, machinery suppliers, steel erection contractors and many others are well established, reliable and independent of any specific project. The steel sector is supported by steel manufacturers, the British Constructional Steelwork Association (BCSA) and the Steel Construction Institute (SCI). Together, they build links throughout the supply chain via component and systems manufacturers, design consultants and academics. Internationally, networks of similar organisations ensure that best practice is maintained, developed and shared worldwide.

[top]Collaboration drives innovation

All members in the steel supply chain work collaboratively together. Interaction between steelwork contractors and professional colleagues is fostered by the nature of steel construction, which promotes collaborative design. Computer modelling is easily shared between contractors, engineers, architects and designers. Such close collaboration leads to innovation, as evidenced by the wide range of market leading systems, products and working methods that have been developed. Improvements in health and safety, productivity and sustainability have been achieved by new innovations, including highly optimised cellular beams and plate girders, pre-fixed edge protection, water-based protective systems and deep decking assembly and erection techniques.

[top]Quality assured at every stage

Quality assurance runs throughout the constructional steel supply chain. Steel sections are manufactured, tested and certified to national and international standards and are delivered with inspection certificates to guarantee their provenance and are UKCA marked (or CE marked until 31 December 2021) to assure customers of compliance with the Construction Products Regulations[5].

[top]Research enhances best practice

The steel supply chain is committed to developing more efficient ways of working together, backed by extensive investment in research and development. The results of this investment can be seen in the wide range of detailed reports published on everything from the performance of steel in fire to the acoustic and vibration performance of buildings. Guidance on these and all other technical issues is provided free to designers.

[top]Sector support

The UK steel sector provides an unparalleled level of coordinated support, advice and guidance to specifiers, designers and clients. The steel sector undertakes extensive research and development into the properties of steel and how it can best be designed, fabricated and erected. No other construction material has enjoyed such a sustained track record of major investment in technical research and development. The sector works hard to ensure that the knowledge gained from this research is disseminated as widely as possible throughout the construction community.

[top]Technical support from the specialists

Comprehensive technical support is available for specifiers, clients, architects, designers and cost consultants via this website and the advisory services run by BCSA and SCI for their members. This expert advice covers the design and construction of buildings and bridges, as well as a range of technical topics including fire, durability and sustainability. An extensive range of support material is available, including design guides covering all aspects of steel construction. Significant resources have been committed by the sector to prepare design guidance, training aids and web-based learning packages to ensure that structural engineers have all the information they need to design to Eurocode standards.

[top]Advances in academia

The steel sector maintains close relationships with universities and other educational and research institutions in the UK, supplying extensive teaching resources, providing bursaries, and sponsoring university academic posts.

[top]Customised training courses

Technical courses and seminars are arranged by the BCSA and SCI. The online CPD presentations on this website are free of charge and are a popular way of keeping up-to-date with the latest design and construction techniques. Continuing Professional Development (CPD) courses can also be customised to fit individual company’s objectives, with in-house training available. CPD resources are available here.

[top]Structural steel solutions

Steel-framed structures offer the benefits most prized by designers and building owners, enabling large column free floor areas to be created along with minimum floor construction depths. Steel-framed buildings also require smaller foundations than concrete alternatives and can be erected in a fraction of the time.

The columns supporting steel-framed buildings are relatively small and can be easily hidden within the width of partitions. Composite floor slabs deliver significant advantages, enabling shallow floor depths to be achieved. Up to 400m² of composite floor decking can be installed by a single team in one day, with no requirement for extensive shuttering, propping, on site storage of materials and time-consuming striking of shuttering associated with concrete construction.

Simplicity and adaptability

Steel-framed buildings provide safe working areas for other members of the build team and follow-on trades during the construction process. The fixing arrangements for services and ceilings are straightforward too, and simple connections to floor decking provide the flexibility to install new service arrangements during a building’s lifetime[6].

Integrated services

In many modern commercial buildings there is a need to incorporate air-conditioning ducts and extensive wiring for IT equipment within the floor depth using false floors and ceilings. Steel-framed buildings are the ideal, cost-effective solution in these situations, since services can be integrated within the supporting steelwork. Steel can provide several long span solutions, all incorporating integrated services. Where service integration is not a factor, steel floors as shallow as 200mm can be supplied, using bespoke fabricated floor beams.

Future-proofing

Choosing a steel frame is a good way to ensure a long life for your building. Steel is durable and easily adaptable, particularly in comparison to the inflexibility of concrete structures. Steel-framed structures provide ‘future-proofing’ against changing service requirements, changes in technology or in building use. Over-provision of perforations in beam webs facilitates this future flexibility, allowing entirely new service arrangements to be accommodated within the structural steelwork.

[top]Structural steel's track record

The figure shows the market share for structural frames in UK multi-storey buildings over the past 30+ years. From a market share of 33% in 1980, steel has grown and sustained its market share at around 65-70% over the past 20 years; demonstrating that steel continues to meet the requirements of modern, multi-storey buildings.

[top]References

- ↑ Approved Document E (Resistance to the passage of sound) 2003 Edition incorporating 2004, 2010, 2013 and 2015 amendments. Ministry of Housing, Communities & Local Government

- ↑ The Green Guide to Specification, 4th ed., BRE and Oxford Brookes University, 2009

- ↑ ISO 14001:2015. Environmental management systems - Requirements with guidance for use.

- ↑ BES 6001: ISSUE 3.1 Framework Standard for the Responsible Sourcing of Construction Products, BRE Environmental & Sustainability Standard, 2016

- ↑ 5.0 5.1 For the purposes of this article CPR refers to The Construction Products (Amendment etc.) (EU Exit) Regulations 2019 (S.I. 2019/465) and provisions in the European Union (Withdrawal Agreement) Act 2020 (Commencement No. 1) Regulations 2020 (S.I. 2020/75)

- ↑ Supporting services from structure. BSRIA/SCI, September 2004

[top]Further reading

- Steel Buildings, BCSA No. 35/03

- Steel Designers' Manual 7th Edition. Editors B Davison & G W Owens. The Steel Construction Institute 2012

[top]Resources

- SCI P354 Design of floors for vibration: A new approach (Revised Edition)

- SCI P372 Acoustic Detailing For Steel Construction

- Carbon footprint tool for buildings

[top]See also

- Health and safety

- Fabrication

- Vibrations

- Acoustics

- Recycling and reuse

- Fire and steel construction

- Cost of structural steelwork

- Modular construction

- Long-span beams

- Infill walling

- Multi-storey office buildings

- Composite construction

- Design codes and standards

- The recycling and reuse survey

- Steel and the circular economy