Steel and the circular economy

This article addresses the developing circular economy agenda and specifically, steel and steel-framed buildings’ circular economy credentials.

All steel construction products are inherently recyclable however, structural steel elements are also inherently reusable. Many of the attributes of steel and steel structures are covered elsewhere on this website but are brought together here in the context of the evolving circular economy agenda.

[top]What is the circular economy?

Main articles: Construction and demolition waste, Recycling and reuse, The recycling and reuse survey

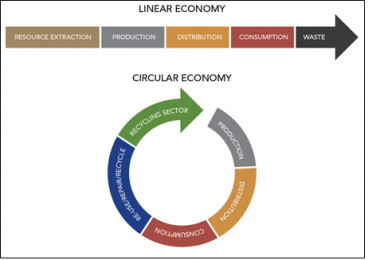

A circular economy is an alternative to a traditional linear economy (often described as a take, make, use, dispose economy) in which we keep resources in use for as long as possible, extracting the maximum value from them while in use, and then recover and regenerate products and materials at the end of each service life. Since the last industrial revolution, economic growth has been strongly coupled to primary resource consumption; circular economy models attempt to decouple economic growth and resource use since it is recognised that current global consumption patterns are not sustainable.

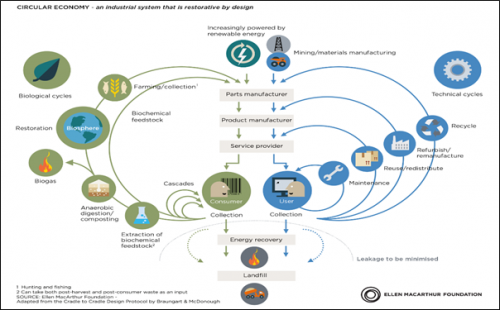

The figure (right), developed by the Ellen McArthur foundation, is one of the best accepted representations of circular economy concepts. The left hand (green) half of the figure represents biological cycles such as timber and the right hand side (blue) represents technical materials, including, in the context of construction, concrete, metals, plastics, etc.

There are two fundamental concepts to highlight within the figure:

- Leakage out of the circular system, to energy recovery or landfill, should be avoided wherever possible

- Within the concentric circles, the smaller the diameter the more efficient the process.

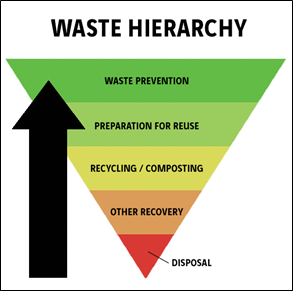

The Ellen MacArthur figure is in fact conceptually, very similar to the EU and UK waste hierarchy which ranks waste management options according to what is best for the environment and has been a central concept in EU and UK waste policy frameworks for many years.

Within the context of the circular economy it is important to understand the difference between reuse and recycling. This is particularly important in the case of the term recycling which has a loose definition in general parlance but a more specific definition within waste management and the circular economy. The following definitions have been used in this article:

- Recycling is the process of converting waste materials into new materials and products; these can be the same or different to the original material or product. Generally the recycling process requires energy.

- Reuse is defined as the subsequent use of an object (in its original form) after its first life. It may be repurposed, but the object will only have minor alterations, retaining a similar (or the same) form.

It is important to differentiate between different types of recycling since the environmental or circular economy benefit (generally assessed using life cycle assessment) can vary significantly:

- True or closed-loop recycling in which products are recycled into products with exactly the same material properties. An example of true recycling is recycling steel by remelting

- Downcycling which describes the process of converting materials into new materials of lesser quality and reduced functionality. Examples of downcyling in construction include crushing concrete to produce aggregates for fill and chipping timber products to produce chipboard, or animal bedding etc.

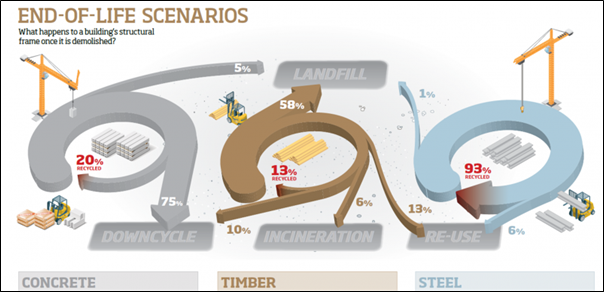

Within the circular economy, the end-of-life credentials of construction products are important because although buildings are generally long-lived products, they do consume significant material resources and unless we keep these resources in-use, through reuse or true recycling, circularity is lost. Structural materials differ significantly in their end-of-life credentials; this is a function both of the inherent material properties and the resulting structural forms.

The UK Green Construction Board is working to embed circular economy thinking in the built environment and have developed a useful interactive knowledge resource for circular economy thinking in construction.

[top]Construction and demolition circular economy drivers

At a macro level, circular economy drivers include:

- Global population growth and rising standards of living leading to greater demand for resources which is unsustainable following existing linear models

- Security of supply and price volatility particularly for important resources such as rare earth minerals but also energy

- Environmental impact of winning new resources; for many materials and products, recycling has a lower environmental impact than producing then from primary resources.

In terms of policy, the most significant driver is the EU Circular Economy Package which was launched in 2015. The Package, which includes revised legislative proposals on waste, includes measures to stimulate Europe's transition towards a circular economy which aims to boost global competitiveness, foster sustainable economic growth and generate new jobs.

Proposed actions will contribute to "closing the loop" of product lifecycles through greater recycling and re-use, and bring benefits for both the environment and the economy. The plans aim to extract the maximum value and use from all raw materials, products and waste, fostering energy savings and reducing greenhouse gas emissions. The proposals cover the full lifecycle: from production and consumption to waste management and the market for secondary raw materials.

The Circular Economy Package gives a clear signal to economic operators that the EU is using all the tools available to transform its economy, opening the way to new business opportunities and boosting competitiveness. The broad measures for changing the full product lifecycle go beyond a narrow focus on the end-of-life stage and underline the Commission's clear ambition to transform the EU economy and deliver results. Innovative and more efficient ways of producing and consuming should increasingly emerge as a result of the incentives we are putting in place.

Although the EU CE Package covers all economic activity, many of the proposed measures are directly applicable to the construction industry.

Construction and demolition waste (CDW) is one of the heaviest and most voluminous waste-streams accounting for around 31% of total waste generation. Consequently, CDW has been identified as a priority waste stream by the European Union.

Key actions adopted by the EU include:

- Development of quality standards for secondary raw materials

- Development of eco-design measures

- Revisions to waste legislation including target setting to reduce landfill and increase recycling

- Promotion of economic instruments to discourage landfilling

- Simplified and improved definitions and harmonised calculation methods for recycling rates throughout the EU

- Measures to promote re-use and stimulate industrial symbiosis – turning one industry's by-product into another industry's raw material.

In the latest communication on the Circular Economy Action Plan (2020)[1], the EC has stated their intention to exploit the potential for increasing material efficiency and reducing climate impacts by launching a new comprehensive Strategy for a Sustainable Built Environment. This Strategy will ensure coherence across the relevant policy areas such as climate, energy and resource efficiency, management of construction and demolition waste, accessibility, digitalisation and skills. It will promote circularity principles throughout the lifecycle of buildings by:

- addressing the sustainability performance of construction products in the context of the revision of the Construction Product Regulation, including the possible introduction of recycled content requirements for certain construction products

- promoting measures to improve the durability and adaptability of built assets in line with the circular economy principles for buildings design and developing digital logbooks for buildings

- using Level(s) to integrate life cycle assessment in public procurement and the EU sustainable finance framework and exploring the appropriateness of setting of carbon reduction targets and the potential of carbon storage

- considering a revision of material recovery targets set in EU legislation for construction and demolition waste and its material-specific fractions

- promoting initiatives to reduce soil sealing, rehabilitate abandoned or contaminated brownfields and increase the safe, sustainable and circular use of excavated soils

Although the UK was generally supportive of the EU Circular Economy Package, it is unclear, post-BREXIT, how UK policy to deliver a more circular economy will evolve. It is noted that in a statement issued in July 2020, the UK Government reinforced its commitment to align with the EU Circular economy package.

Under the Green Construction Board (GCB) the UK Government is working with the construction industry, to provide leadership in the move towards more CE thinking. More information on the GCB’s work is available here.

WRAP has been a leading UK player in waste and resource efficiency since 2000. WRAP has developed a 2020 vision for a more circular UK economy focussed using fewer materials, reducing waste and increasing recycling. It is noted that WRAP’s vision is not UK Government policy.

[top]Benefits of the circular economy

There have been a number of studies quantifying the potential economic opportunity/benefits of the circular economy. Some of the predictions are staggering and include:

- $4.5 trillion globally next 15 years (Accenture Waste to wealth: creating advantage in a circular economy)

- UK NMR £10 billion profit increase (Next manufacturing revolution (2013))

- $380 billion pa EU material cost savings (Ellen MacArthur Towards the circular economy (2013))

- Europe net economic benefit €1.8 trillion by 2030 (Growth within: a circular economy vision for a competitive Europe McKinsey (2015))

Some experts predict that the circular economy will drive the next (fourth) industrial revolution.

As well as creating opportunities for economic growth, a more circular economy will:

- Reduce waste

- Drive greater resource productivity

- Deliver a more competitive UK economy.

- Position the UK to better address emerging resource security/scarcity issues in the future.

[top]Steel’s circular economy credentials

Main article:The case for steel, Sustainability, Recycling and reuse, Cost of structural steelwork

Steel has excellent circular economy credentials both as a material which is strong, durable, versatile and recyclable and, as a structural framing system, which is lightweight, flexible, adaptable and reusable. Steel’s combination of strength, recyclability, availability, versatility and affordability makes it unique.

[top]Durability

Main article: Corrosion protection

A circular economy promotes long product lives. Maintaining products at their highest utility and value for as long as possible, is a key component of the circular economy. Put simply, the longer a product lasts the less raw materials will need to be sourced and processed and less waste generated. Steel construction products are inherently durable meaning not only that will they last a long time but also that many steel construction products can be reused after their first life.

Properly designed and, where appropriate, properly protected steel structures provide long-term durability. Buildings like the National Liberal Club in London (1887) and structures like the Forth Rail Bridge (1890) demonstrate the longevity of steel buildings and structures.

Guidance is available on standard corrosion protection systems for steel-framed buildings including paint and metallic coatings.

[top]Versatility

Main articles: Recycling and reuse, Steel material properties

Steel is a versatile material both in terms of its metallurgy/chemistry and as a construction product and structural framing system:

- Steel is infinitely recyclable

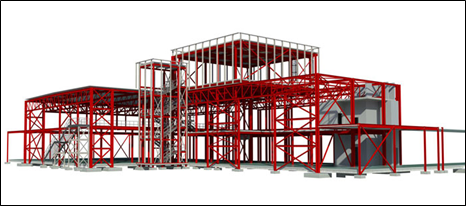

- Structural steel products are durable, robust and dimensionally stable elements that are generally bolted together to form structural assemblies; as such they are inherently demountable and reusable

- Steel structures can be easily extended and reconfigured in-situ to extend building lives.

Steel is not a single material. In fact there are more than 3,500 different compositions or grades of steel with different physical, chemical, and environmental properties; each tailored to specific applications in sectors as diverse as packaging, engineering, white and yellow goods, vehicles and construction.

Approximately 75% of modern steels available today have been developed in the past 20 years. If the Eiffel Tower were to be rebuilt today, engineers would only need one-third of the steel that was originally used (in 1889) because of the strength and quality improvements achieved by the steel industry over the last century.

Construction is the largest market sector for steel in the UK accounting for around one third of all consumption. Steel’s versatility promotes recycling since steel scrap can be blended, through the recycling process, to produce different types of steel (different grades and products) that meet changing demands over time. For example, steel from redundant industrial machinery can be recycled into more contemporary products such as cars or white goods which, in turn, can be recycled into new, maybe as yet undiscovered, applications in the future. The Lackenby Meltshop case study demonstrates this versatility in practice.

The construction industry only uses a relatively small number of steel grades although advances in metallurgy enable the design of lighter structures using higher strength steel sections.

For example, an S460 grade beam weighs 32% less than a standard S355 grade beam of the same length and thickness. Material savings are around 30%. These new steels satisfy the demands of architects and designers for materials which enable them to create light and economical structures.

[top]Recycling

Main articles: Recycling and reuse,The recycling and reuse survey

Steel is 100% recyclable without loss of its inherent material properties and is the most recycled industrial material in the world, with over 650 Mt recycled annually.

Steel’s two key components are iron ore, one of Earth’s most abundant elements, and recycled (scrap) steel. Once steel is produced (from iron ore) it becomes a permanent resource for society; as long as it is recovered at the end of each product life cycle, because it is 100% recyclable without loss of quality.

In theory, all new steel could be made from recycled steel. However, this is not currently possible because global demand for steel exceeds the supply of scrap. This imbalance is due to steel’s global popularity and its durability; meaning that an estimated 75% of steel products ever made are still in use today.

Steel products in-use today all contain a proportion of recycled steel from previous incarnations; this can be one or many previous uses. Originally this ‘recycled’ steel was produced from iron ore and therefore how the initial impacts of primary production, are shared over subsequent uses of the same material is an important question in quantifying its whole life environmental impacts.

As long as recycling continues therefore, the life of a steel product (or more accurately the steel within it) is, in effect, infinite and individual incarnations or uses of a steel product, are merely parts of the larger life cycle of the material. By considering the environmental impact of these intermediate lifecycle stages in isolation, an incomplete, ‘snap-shot’ of the overall impact is obtained. For example, by only considering the recycling step but excluding the initial, generally larger, impact from the initial primary production. This is further explained here.

Steel recycling rates vary by country and product type. Two UK studies have been undertaken to estimate the recycling rates of structural steel. The most recent survey (2012) shows that 100% of structural steel sections is recovered from demolition; 93% for recycling and 7% for reuse.

[top]Lightweight

Main articles: Target Zero

Using less materials is another key component of the circular economy.

Steel is strong and has a good strength-to-weight ratio. Compared to other commonly used, structural materials, steel buildings are lightweight meaning that significantly fewer materials are required to construct them.

Not only does this reduce the weight and the environmental impact of the above ground structure, but importantly, it can also reduce foundation loads meaning that fewer and smaller foundations are required compared to heavier structural forms.

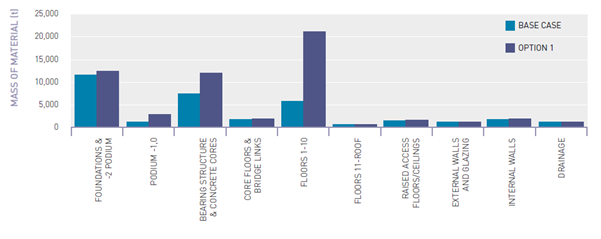

As part of the Target Zero study, the weights of equivalent steel and concrete-framed buildings were compared. The designs were independently undertaken by AECOM and the quantities (and costs) calculated by the Sweett Group (now part of Currie & Brown).

The building on which the office building research was based is One Kingdom Street, located in the Waterside regeneration area near Paddington railway station in Central London. This Grade A office building was completed in 2008.

The building was designed to achieve the maximum floor plate depth consistent with British Council for Offices (BCO) guidance. A typical office floor plate provides approximately 2,500m² of highly flexible space on a 1.5m planning grid. Two structural forms were compared:

- Cellular steel beams supporting a lightweight concrete slab on profiled steel decking (Base case)

- 350mm thick post-tensioned concrete flat slab (Option 1)

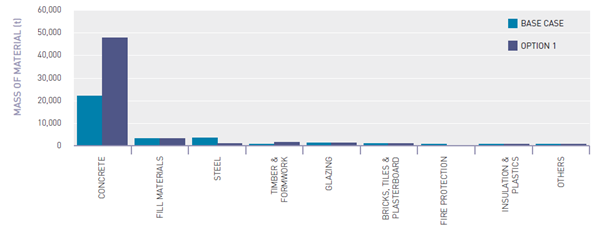

The figures below show the mass of materials used to construct each of the two office building alternatives, broken down by building element and material type. The total mass of materials used to construct the office building was 32.3mt for the steel-framed Base case compared to 55.4mt for the concrete-framed option, i.e. the concrete-framed building was 72% heavier than the steel-framed building.

The figures show that most of the materials are used in the foundations (22% to 36%), bearing structure (22% to 23%) and particularly the upper floors (31% to 50%). Concrete is by far the most abundant material used to construct the office building representing between 68% (Base case) and 86% (Option 1) of all materials by weight. Compared to the base case building, the post-tensioned concrete building (Option 1) requires an additional 25,692kt of concrete.

For further information and results see the Target Zero office design guide.

[top]Steel by-products

Main articles: Steel manufacture

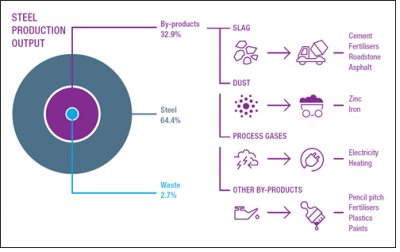

Material efficiency is an integral part of the modern steelmaking process. The goal is to use all raw materials to their full capacity and eliminate waste from steelmaking. This approach includes industrial symbiosis in which almost every by-product formed during steelmaking is used in new products. This minimises the amount of waste sent to landfill, reduces emissions, and preserves raw materials.

As with all large-scale manufacturing processes, the production of iron and steel generates by-products. On average the production of 1 tonne of steel results in 200 kg (EAF) to 400 kg (BF/BOF) of by-products.

The main by-products produced during iron and steel production are slags (90%), dusts and sludges. The worldwide average recovery rate for slag varies from over 80% for steelmaking slag to nearly 100% for ironmaking slag.

Slag is used to make a range of products including cement, fertilisers, and asphalt. Process gases from iron and steelmaking are typically used within the steelmaking plant, replacing steam and electricity, or exported to the local grid. Other by-products such as dust are reclaimed for their high metallic content.

[top]Reuse and remanufacture

Main articles: Recycling and reuse

Structural steel sections are inherently reusable. Reuse, as opposed to the current, common practice of recycling structural steel by remelting, offers significant potential in terms of resource efficiency and carbon emission savings.

There are many steel-based temporary works systems which are highly reused (see below); the challenge it to develop permanent works systems that are similarly reusable.

Reusing reclaimed structural steel is not a new idea; in fact, the practice was more prevalent in the past but has declined over the last few decades. There are several reasons for this the most significant including (new) development programme constraints and tougher health and safety requirements in relation to demolition activities, in particular, working at height.

Reuse is technically viable, as demonstrated by isolated projects and in certain niche markets, but there are barriers to mainstream reuse.

Steel reuse generally happens in three main ways:

- In-situ reuse in which the structural frame is reused, with or without alterations, in-situ. This is generally associated with refurbishment projects and it is currently the most common way of reusing structural steel in the UK

- Relocation reuse involves deconstruction of an existing steel frame, which is then transported and re-erected, generally in its original form, at a different location for the same or similar purpose

- Component reuse involves careful deconstruction of an existing structure where individual structural steel members are reclaimed and used to construct a new permanent structure.

Reusing simple, low-rise structures such as portal frames, is relatively common particularly in the agricultural sector. Larger, whole building reuse is less common (other than in-situ refurbishment) but there are some examples, such as the SEGRO case study, where this has worked well under certain scenarios. Component, i.e. beam or column, reuse is relatively rare and often challenging on large projects but is relatively commonplace for small-scale domestic projects.

Some steel stockists offer reclaimed steel sections alongside new steel and others offer excess, unused steel tube from the offshore industry for use in the construction industry particularly for piling.

The SCI, working together with the University of Cambridge, has recently completed two research projects into structural steel reuse exploring the barriers to more mainstream reuse, the economics of reuse and assessing the feasibility of developing a website for trading and sharing information about reclaimed structural steel.

Summary conclusions from these studies include:

- Structural steel (open or closed) sections are durable and dimensionally stable construction components. Of the range of steel products used in construction, they are considered to be the most suitable steel products for reuse.

- Consultations with the supply chain, confirm the technical viability but also identify the many, real and perceived, barriers to reuse; particularly to more mainstream reuse. These include barriers across the supply chain, particularly the additional cost and longer procurement and construction programmes.

- Based on consultations with the steel construction supply chain, the overall ranking of barriers in descending order of importance, is:

- Availability of reclaimed sections particularly of the desired size, volume and in the right place at the right time

- Issues relating to the quality, traceability and certification of reclaimed sections

- Additional cost associated with using reclaimed sections

- (Lack of) supply chain integration; particularly communication and sharing information through the supply chain and trust (and risk sharing) between companies

- Additional time required within construction programmes to allow for using reclaimed steel; in general, additional time incurs addition cost

- Reclaiming and reusing structural steel is a relatively uncommon practice and many organisations simply do not have the skills or experience to do it

- The perception that reclaimed steel is somehow inferior to new steel sections.

- The historical (2000-16) price range between new steel sections and scrap sections (grade OA scrap) reveals an average price difference of £313 per tonne over this timeframe. This differential represents the profit opportunity for reuse before the additional deconstruction costs (testing and certification, storage and refabrication costs) are taken into account.

- The economic case for widespread reuse today is marginal. Under current UK economic and legislative conditions, the conclusion is that, other than the small-scale and niche markets identified and under certain project specific circumstances, mainstream structural steel reuse is not viable today. The lack of economic incentive is compounded by the lack of any legislative drivers. We conclude that in the short-term, this situation in the UK, is unlikely to change dramatically. There are however potential macro-economic benefits through steel reuse since currently around 70% of UK steel scrap is exported whereas a larger reuse market would retain greater economic value within the UK.

Although more mainstream structural steel reuse is unlikely under current UK economic and legislative conditions, BIM technologies overcome several of the barriers to steel reuse by providing certainty about material properties, traceability and provenance and eliminating the need for testing. Looking ahead therefore, structural steel (BIM) models offer a cost effective means of enabling future reuse.

Steelwork contractors have been using BIM models for years and routinely offer their clients as-built structural models on building handover. By storing such models in a secure database, this will future-proof UK steel structures and will assist with refurbishment, extension and eventually deconstruction of the building to facilitate reuse of the steel elements or optimising the recycling process. The UK steel construction sector is exploring how to provide a service to do this.

[top]Flexibility and adaptability

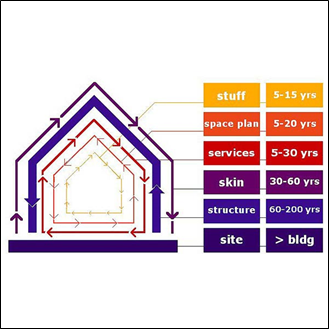

Extending the life of buildings is another key aspect of the circular economy. This can be achieved by making buildings that are both flexible and adaptable to change so that they last longer and greater value is extracted from the materials and resources used to construct them.

The pace of change in all walks of life has never been greater. Changing work patterns, new building services and information technologies, changing demographics and new legislation are all putting new and different demands on buildings. Sustainable buildings should be flexible to change of use and adaptable to future needs and requirements be they regulatory or market driven.

Difficulty in adapting buildings to change often leads to their premature redundancy and subsequent demolition. Even before redundancy, failure or inability to adapt and upgrade buildings can compromise occupant comfort and, in commercial buildings, reduce their productivity.

Although the definitions of adaptability and flexibility are often blurred, the following definitions are generally adopted:

- Adaptable building - a building that has been designed, constructed and maintained with thought of how it might be easily altered to prolong its life, for instance by addition or contraction, to suit new uses or patterns of use (adapted from Addis and Shouten[2])

- Flexible building - a building that has been designed to allow easy rearrangement of its internal fit out and arrangement to suit the changing needs of occupants (Addis and Shouten[2]).

In addition, adaptable buildings should be designed to be able to accommodate the predicted impacts of climate change, for example higher temperatures, higher and more concentrated rainfall and more frequent and severe storm events, including flood resilience.

The useful life of buildings can be extended through the adaptation and reconfiguration of internal space and walls, structural extension and upgrading of the external envelope, etc. In these ways the life cycle costs and the environmental impacts of the building are reduced as more value is obtained from the same resources.

There are three principal areas in which buildings can be made more flexible and/or adaptable:

- Structural extension (vertically or horizontally) to accommodate change of use or the changing requirements of the building owner

- Internal flexibility to accommodate change of use, different working patterns or the requirements of different tenants/owners

- Flexible building services to enable servicing upgrades or change of building use without impacting the structure.

Steel-framed buildings are among the most adaptable and flexible assets a business can invest in. The steel frame itself can be easily adapted, with parts added or taken away, and its light weight means that extra floors can often be added without overloading existing foundations.

Steel structures are commonly used to renovate buildings for example behind retained facades. In this way the historic value, character and resources of the façade are retained and the building structure can be reconfigured to create open, flexible internal space that meets modern client requirements and maximises net lettable floor area.

Kinnaird House (below) was constructed in the early 1920s using Portland stone held in place by an integral steel frame. The client's main criterion for the redevelopment was that the existing character of the building should be maintained while maximising the net lettable floor area.

This was achieved using a shallow floor system, tied to the original steel stanchions, and lightweight concrete on steel decking. The consequential reduction in load carried by the foundations enabled an additional floor to be inserted into the old banking hall area and an extra floor to be added for plant at roof level. The shallow floor construction also allowed an unhindered services zone across each floor plate. The redevelopment of Kinnaird House achieved an excellent BREEAM rating.

- Kinnaird House, London, Architect: Trehearne Architects

Shallow floor system behind the retained facade

The large column-free spaces created by long span steel sections mean that buildings can be constantly adapted to cope with the changing requirements of its occupants. Building interiors can be easily and economically adapted, avoiding the high costs of redevelopment or demolition.

Having fewer columns provides a major benefit to building owners and users, as it is easy to subdivide space or alter it in any way that changing circumstances demand. In competitive property markets open spaces provided by constructional steelwork allow premium rents to be charged.

The St John Bosco Arts College in Liverpool is a great example of a flexible steel-framed building. Eleven large trusses support the roof and create 55m-wide column-free space that provides flexible space that can be reconfigured or changed using movable partition walls.

Steel frames also offer many solutions to integrate building services within the structural floor zone including systems such as shallow floor construction and long-span beams with regular or tailor-made openings in the beam webs.

The basic decision to either integrate the services within the structural depth or to suspend the services below the structure affects the choice of structure, the fire protection system, the cladding details and the overall building height. There are two general approaches to design to accommodate the horizontal distribution of services:

- Minimise the structural zone so that services pass underneath. This is the approach used in shallow floor construction in which the structural zone is only around 300mm.

- Distribute services within the structural zone, for example by provision of large openings within the depth of the steel beams. This is best achieved in long span construction where the beam depth is dictated by structural requirements and large openings can be provided within this depth

Flexible services distribution has a double benefit, initial design and construction programming is made easier since the structural design and fabrication can be progressed before the precise service requirements and routing is finalised. Also the building is more adaptable to meet future servicing requirements resulting from, for example, a change of use or tenant or simply to upgrade the services.

More detailed guidance on service integration within steel-framed buildings is available.

[top]Design for deconstruction and reuse

Design for deconstruction and reuse is an important discipline in sustainable construction and central to the circular economy. Current practice, driven by cost, programme and H&S constraints, is generally to demolish buildings with little thought about preserving the integrity and value of components for reuse. Only by designing buildings for deconstruction can we make reuse of building components more commonplace.

The ability to reuse building components is, to a large extent, dependent on how buildings have been constructed in the first place. Although designers routinely consider the constructability of buildings, historically little thought is given to their deconstruction and how elements and components could be reclaimed and reused.

By ‘Designing for Deconstruction’ (DfD) there are long-term savings to be made in the amount of material used and the associated embodied carbon as well as reduced waste arisings. This can be achieved by ensuring that components that are specified can preferably be reused rather than recycled or downcycled at the end of their life; maintaining their value. DfD is one of the key parts of the jigsaw to assist the construction industry in achieving higher levels of resource efficiency and embedding circular economy thinking.

At its simplest level, there are two main considerations:

- The types of materials and components used; some products, like structural steel, are inherently more reusable than other structural materials and systems.

- The way the materials and components are put together (thus able to be taken apart) and deconstructed.

WRAP has defined Design for Deconstruction and Flexibility (DfDF) as one of the five principles for designing out waste within its Designing out Waste Guide. Consideration of DfD needs to be embedded within the key stages of the design process to ensure it is considered at the earliest stages of a construction project where the opportunity for influence is at its greatest. According to BS 8895-2[3], consideration of DfD should be given where feasible during the Concept and Developed design stages of the RIBA Plan of Work Stages

Common principles to follow in design for deconstruction and reuse are:

Design principles

- Simplicity – design building systems and interfaces that are simple to understand, with a limited number of different material types and component sizes.

- Transparency – design building systems that are visible and easy to identify

- Standardisation and regularity – design building systems and materials that are similar throughout the building and laid out in regular, repeating patterns. Where possible, standardise elements

- Design the building to be built from the ground up and avoid transfer systems that ultimately support the structure from above.

- Design for prefabrication, preassembly and modular construction: Prefabricated units are easily deconstructed and modularity allows assemblies rather than individual elements to be reused.

- Simplify and separate building systems – use a ‘layering approach’ to keep elements of the building (with different anticipated lifetimes) separate

- Use mechanical/gravity-based design principles in preference to chemical-based design.

Materials and components

- Minimise the number of different types of materials

- Minimise the number of types of components – fewer larger elements which are more durable and easier and quicker to remove are more likely to be reused

- Minimise the number of members required. This reduces the complexity both in construction and deconstruction. Longer members are more readily usable - it is easier to trim a member to the required length than extend it.

- Avoid secondary finishes to materials

- Size components to suit means of handling and provide adequate access to components and their connections

- Apply realistic tolerances during manufacture

- Use lightweight materials and components

- Use reusable materials: chose materials that are inherently durable and reusable and retain their value through reuse

- Use durable components - it is important that the components that can be readily recovered without damage are durable enough to be repaired or reused with the minimum of work and cost.

- Identify points of disassembly and ensure they remain accessible.

Connections and fasteners

- Simplify and standardise connection details: This allows for efficient construction and deconstruction and facilitates reuse without modification after deconstruction..

- Use mechanical fasteners in preference to chemicals such as sealants and adhesives.

- Make connections visible/accessible

- Use bolted connections in preference to welded connections

Elements

- Design for modular and panelized elements that are readily fit into common dimensional standards and possible de-panelization – this is also related to design using standard structural and planning grids.

Construction information

- Record as-built conditions, i.e. what was built not just what was designed

- Provide a deconstruction plan outlining general concepts where the load path for the self-weight of structure and deconstruction loads follow conventional paths. Provide specific detailed plans where load paths are not conventional. All load transfer systems should be identified.

- Record adaptations to building over its life

- Ensure information is securely stored and remains accessible.

Specifically in relation to structural steel:

- Provide clear documentation of all steel members used in the structure, including, size, grade, length, and connection details

- Keep records of the steel supplied, specifically mill test certificates including manufacturer, production date and standard.

- Ideally steel members should have a permanent marking or tagging to assist in traceability and to identify chemical and mechanical properties.

Park 2020 is a business park near Schiphol airport in the Netherlands. The Fokker distribution centre is a cradle-to-cradle (C2C) certified steel-framed building designed to be demountable and reusable. The building includes a number of new, circular economy principles including:

- Development and use of a ‘Building Material Passport’ which contains the specifications of the steel used in the building.

- Demountable connections for beams, columns and cladding. These connections eliminate on-site welding, and the need for adapted anchor bolts and shot connections.

- Shear stability is provided by horizontal steel trusses instead of flooring.

- The entire building is designed with modular (standard) steel beam and column dimensions, lengths and sizes.

[top]What next for steel and the circular economy?

The circular economy is an important, evolving agenda. However, the need to move towards a more circular economy is not in doubt nor are the potential economic opportunities.

Steel, both as a material and a structural framing system, already has excellent circular economy credentials, inherent attributes that cannot be matched by competing structural materials. Structural steel also has the advantage that it can go further and deliver truly circular demountable and reusable buildings.

New legislation, technical developments and different business models are required to realise these opportunities but the steel sector is ready and working, in partnership with its supply chain, to deliver the circular economy.

SCI has recently completed two, large European research projects exploring the potential for greater reuse of structural steel and developing new technologies for facilitating easier and more efficient deconstruction and reuse.

In the context of multi-storey buildings, this has included:

- Opportunities for greater standardisation of structural grids to facilitate future reuse

- Optimised span:depth ratios for steel and composite beams

- Opportunities for greater standardisation and adjustment of connections to facilitate deconstruction

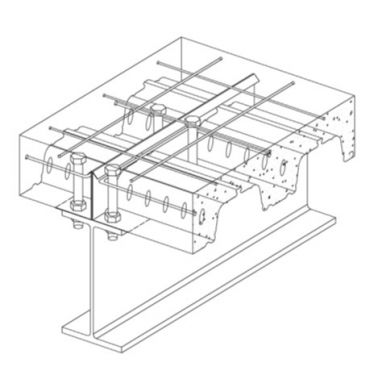

- Development and testing of new, demountable composite flooring systems

- Development and testing of adjustable and demountable connection systems

SCI has published (SCI P428) guidance on the design of composite beams using demountable shear connectors based on BS EN 1994-1-1[4]. The design methodology takes account of the different characteristics of the demountable shear connectors, in terms of their shear resistance, stiffness, and ductility. Design data on the performance of two types of demountable shear connector, using high-strength structural bolts and coupler systems, are presented.

- Demountable shear connectors with partial depth edge trim and U-bars

In the context of single storey, portal frame buildings, design for deconstruction and reuse research has included:

- Recommendations for standardised span increments and frame spacing

- Development of bolted haunch connection details

- Alternative column base connections which are accessible and demountable

In addition, the application of BIM to enable and facilitate future deconstruction and reuse has been explored and a cloud-based prototype developed to store section details of all new steel structures erected in the UK. This will provide full traceability of steel sections so that they can be safely and efficiently reused in the future.

To help facilitate the reuse of existing structural steel, SCI has published a protocol (SCI P427) setting out recommendations for data collection, inspection and testing to ensure that reclaimed structural steelwork can be reused with confidence.

The building below, shows a steel-framed building that has been demounted, relocated and reused not just once but twice during its lifetime!

[top]References

- ↑ Circular Economy Action Plan, For a cleaner and more competitive Europe, European Union, 2020

- ↑ 2.0 2.1 W.Addis & J.Schouten, Design for Deconstruction: Principles of Design to Facilitate Reuse and Recycling, CIRIA, 2004.

- ↑ BS 8895-2:2015 Designing for material efficiency in building projects. Code of Practice for concept and developed design. BSI.

- ↑ BS EN 1994-1-1: 2004 Eurocode 4. Design of composite steel and concrete structures. General rules and rules for buildings. BSI

[top]Further reading

- Sustainable materials - with both eyes open. J Allwood and J Cullen, Department of Engineering, University of Cambridge, UIT, 2012.

- Steel - the permanent material in the Circular Economy, worldsteel, 2016.

- Steel in the circular economy - A life cycle perspective, worldsteel, 2015.

- Towards the circular economy: Economic and business rationale for an accelerated transition, Ellen MacArthur Foundation, 2013.

- Growth within: A circular economy vision for a competitive Europe, Ellen MacArthur Foundation, 2015.

- Delivering the circular economy - A toolkit for policymakers v1.1, Ellen MacArthur Foundation, 2015.

- Building revolutions - Applying the circular economy to the built environment, D Cheshire, RIBA, 2016.

- EU Construction and Demolition Waste Protocol and Guidelines, September 2018, European Commission

[top]Resources

- Carbon footprint tool for buildings

- Steel construction – Carbon Credentials

- Steel construction – Thermal mass

- The whole story – from cradle to grave

- Target Zero – Cost effective routes to carbon reduction

- SCI P427 Structural Steel Reuse, Assessment, testing and design principles, 2019

- SCI P428 Guidance on Demountable Composite Construction Systems for UK Practice, 2020

Target Zero design guides:

- Guidance on the design and construction of sustainable, low carbon office buildings

- Guidance on the design and construction of sustainable, low carbon warehouse buildings

- Guidance on the design and construction of sustainable, low carbon supermarket buildings

- Guidance on the design and construction of sustainable, low carbon mixed-use buildings

- Guidance on the design and construction of sustainable, low carbon school buildings

[top]See also

- Sustainable construction legislation, regulation and drivers

- Construction and demolition waste

- Recycling and reuse

- Life cycle assessment and embodied carbon

- Operational carbon

- Thermal mass

- BREEAM

- Target Zero

- The recycling and reuse survey

[top]External links

- Ellen MacArthur Foundation

- Green Construction Board

- Buildings as Material Banks

- Waste Resources Action Programme (WRAP)