Kelvin Hall Film & Broadcast Hub, Glasgow

Article in NSC February 2022

Repurposing a landmark

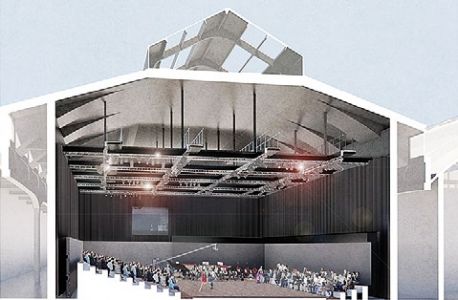

Forming part of the wider redevelopment of Glasgow’s Kelvin Hall, a structurally-independent steel-framed film and television studio is being constructed inside one of its main halls.

Originally built to house large national and international exhibitions, converted into a factory to build barrage balloons during the Second World War and subsequently used to host motor shows, sporting events, and classical and rock concerts, Glasgow’s Kelvin Hall has had a varied existence since it was re-built in 1926-27. Located a few miles west of the city centre, the first Kelvin Hall opened in 1918 and continued a tradition of exhibitions and entertainments on the site including the Machinery Exhibition Hall for the Glasgow International Exhibition of 1901. Unfortunately, the first Kelvin Hall building was rather short-lived at it was destroyed by fire in 1925.

Jump forward to 2022 and Kelvin Hall – which closed its doors in 2014 – is now in the middle of a redevelopment programme, which has already seen two of its four halls return to life as upgraded exhibition space, a sports centre, and a health and fitness club. Phase two is now underway, which includes the construction of the steel-framed Kelvin Hall Film & Broadcast Hub, which is set within hall number three. Once complete, the facility will be operated by BBC Studioworks, a commercial subsidiary of the BBC which provides studios and post-production services to the TV industry.

Co-funded by Glasgow City Council and the Scottish Government, the facility will house a wide array of entertainment shows across multiple genres. It will become the Scottish hub for major TV broadcasters and production companies and will help meet the growing demand for TV shows in Scotland, providing studio space and postproduction services to companies including the BBC, ITV, STV, Sky, Channel 4 and Netflix.

Kelvin Hall is a listed structure and an example of early reinforced concrete construction. Consequently, it is important that any new construction within any of the halls is structurally independent and does not touch the existing building fabric at any point. The main halls (including hall three) are formed with a series of 33.5m-long arched trusses, set at 5.75m centres and supported by 16.7m-high columns. Due to the conservation restrictions, the new Film & Broadcast Hub is formed with a steel frame positioned within the existing column line, while at roof level the new steelwork has been erected under, over and through the concrete trusses to form a new self-contained box.

Woolger Hunter Project Engineer Paula Pappas says: “Steel is lightweight and efficient and allowed an elegant structural design. “Essentially, the building is a braced box with perimeter steel bracing, with secondary and tertiary steel supporting layers for TV cameras and access.” The steel frame is divided into two parts that are acoustically isolated from each other; a column-free studio measuring 28m-long x 30m-wide, and a three-storey element that will contain recording and production suites, costume rooms, green rooms and workshops.

Prior to the new steelwork arriving on site, a thorough laser point cloud survey of the existing building was undertaken in order to detect any potential clashes. “This was very important as the steelwork has been erected very close to the concrete frame in places, particularly in the roof where the main rafters are positioned below the existing trusses, while secondary members and gantry supporting steelwork is above, with some connecting beams passing through the trusses,” says Hescott Engineering Director Chris Scott.

The results from the survey had to be closely coordinated with the foundations to ensure the new structure aligned perfectly with the old and avoided any clashes with the existing structure. “We were working with extremely tight tolerances of up to 50mm, so another thorough survey was needed to ensure each pile cap was in its exact position, because any slight discrepancy would have resulted in clashes between the new and old structures,” adds City Building Senior Contracts Manager Martin Bredin.

Part of the project includes a separate acoustically isolated three-storey block

The studio part of the project is formed with a series of 27.5m-long roof girders, that create the column-free space below. The plate girders are positioned to fit in between the existing concrete bow-string arches and are at 5.6m centres. The five roof girders are each 1.35m-deep and have been designed for specific loadings which will be exerted by not only the roof of the studio box but also various props and equipment that could be hung from the steelwork. The plate girders were transported to Kelvin Hall in three pieces, with the bolted connections made on site, before the assembled 20t sections were lifted into place. Subsequently, a grillage of secondary steelwork has been installed to restrain the top and bottom flanges of girders.

Above the roof girders, an independent structural steel frame has been installed to support lighting rigs, scenery hoists and associated equipment. High level maintenance walkways will span the perimeter of the walls on two sides with access to the production suite rooms behind, while within the studio there will retractable audience seating for approximately 500 people.

Adjoining the acoustically isolated studio, the three-storey element is a separate braced frame, based around a 6m x 7m column grid pattern. A composite solution has been used, with steel beams supporting metal decking and a concrete topping. Each of the three floors has a central corridor, spanned with cellular beams for service integration and also allowing the services to be routed into the rooms on either side. Attached to the outside elevation of the three-storey structure, a tubular steel framework, designed to look like scaffolding, will be erected. This architectural feature is intended to highlight the building’s entrance and will also accommodate walkways at first and second floor level.

The new steelwork elements occupy approximately half of hall three’s footprint. The remainder of the floor space will be given over to scenery storage areas to the north of the studio, while the area to the south of the three-storey frame will cater for seating, bars and other amenities for people waiting to enter the Hub. Overall development will also see the renovation of Kelvin Hall’s main entrance and foyer, while further work is planned for the adjacent hall four.

Summing up, Councillor Susan Aitken, Leader of Glasgow City Council, says: "BBC Studioworks will draw on their wealth of experience in the industry to develop Kelvin Hall as an important and attractive film and television location, continuing Glasgow's rise in this sector. Kelvin Hall will be a nationally significant production facility that will enable productions and jobs to stay and grow in the city, further driving the development of our thriving creative industries, and adding to Glasgow's economic growth."

Kelvin Hall Film & Broadcast Hub is due to open in late 2022.

Plate girders

As used at Kelvin Hall, plate girders can provide a tailor-made solution, sized to suit the

design requirements. David Brown of the SCI summarises the key stages of design.

The new plate girders at Kelvin Hall are an important feature of the redevelopment, providing the necessary column-free space. Erection of the members within an existing structure may be more interesting than the structural design!

The classic approach to plate girder design is to initially assume that the flanges carry the bending moment and the web carries the shear. The web is usually deep, giving a long lever arm between the flanges for increased moment resistance and stiffness, but only needs to be thin. Class 4 webs are to be expected and the relatively thin webs mean that shear buckling must be verified (so designers must turn to BS EN 1993-1-5).

There is no point in exceeding the Class 3 limit for the flange outstands and usually no advantage in choosing proportions to make the flanges Class 1 or 2 – the resistance of the flange is the same. Shear lag, covered by BS EN 1993-1-5 clause 3.1(1), may reduce the effective area of the flange if the outstands are large. The flanges must be checked for plate buckling, and the combined effects of plate buckling and shear lag (Clause 3.3(1)), but this is not expected to significantly reduce the effective area of the flange if it is limited to Class 3. Since the flanges do most of the work in carrying the applied bending moment, it can be effective to use higher strength steel for the flanges with a lower strength web, described in the standard as a “hybrid girder”.

Class 4 webs are more of a challenge, generally resulting in a triangular stress distribution but with a proportion of the compression zone neglected. Designers should note that according to clause 4.3(6), in the case of hybrid girders the effective area of the web must be based on the flange strength. Some iteration with Class 4 webs is needed as the shape of the stress distribution, position of the neutral axis and ineffective area in compression are all interlinked.

Shear buckling of the web is verified in accordance with clause 5.2 and stiffeners, if present. Regular stiffeners act together with the web as a truss – the stiffeners act like vertical posts in compression and the web develops diagonal tension forces in each panel. A stiffened solution can increase the shear resistance by around 30% at the expense of additional fabrication effort.

Detailed advice on the design of plate girders is given in New Steel Construction, June and July 2017.

| Architect | Reiach and Hall Architects |

| Structural Engineer | Woolgar Hunter |

| Steelwork Contractor | Hescott Engineering |

| Main Contractor | City Building |

| Main Client | Glasgow City Council |