Granada Studios redevelopment, Manchester

Article in NSC March 2021

Steel production at former TV studio

The redevelopment of the old Granada Television Studios in Manchester is now in full swing, as the steelwork completes on one of the scheme’s new office buildings.

Some of the UK’s favourite television shows were recorded here, while a number of significant TV firsts were also broadcast from this famous site. The Granada Studios in Manchester were once the headquarters of north west broadcaster Granada Television (later ITV Granada) from 1956 to 2013. During these years, the site became synonymous with the world's longest-running soap drama, Coronation Street, while other long-running programmes such as the quiz show University Challenge and the current affairs documentary series World in Action were also produced here.

History was made at the studios in 1962, when The Beatles made their first television performance and again in 2010 when the UK’s first general election debate was filmed. When ITV Granada, along with Coronation Street’s famous terraced street set, relocated to Salford’s MediaCity in 2013, the studios were said to be the oldest operating purpose-built television studios in the UK.

Jump forward a few years and developer Allied London is now reshaping this historic site into a new mixed-use neighbourhood known as St Johns. Overall, the scheme includes new build elements alongside the refurbishment of existing buildings in order to create a thriving area of homes, workspaces – specifically aimed at the creative industries – retail outlets and leisure facilities.

One part of this ambitious scheme is being undertaken on the plot of the former annex building, where Bowmer + Kirkland (B+K) is constructing a new 10-storey office building. The now demolished annex building once accommodated dressing rooms and the studio’s make-up department. When B+K started work on site in March 2020, it had already been demolished, leaving behind a ground floor slab and a basement. “We kept a retaining wall that was supporting an adjacent road, but apart from that we had to dig-out the slab and basement, and replaced it with a new lower ground floor level topped with a thicker slab to support our new building, which is higher than the previous structure,” explains B+K Senior Site Manager Daniel Jamison.

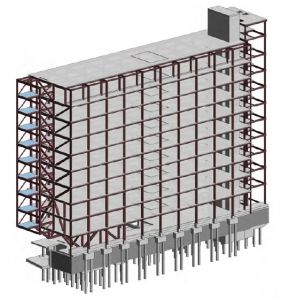

Beneath the reinforced concrete slab and basement, the new steel-framed 10-storey office block is supported by a total of 118 x 7m-deep piles. Taking up the exact footprint of the old annex, the steel-framed structure measures 50m-long × 11m-wide, and it will accommodate around 6,000m2 of office space, along with retail units at ground and lower ground floor.

Explaining the choice of a steelwork solution for the project, Curtins Senior Engineer Rosie Boroujerdi says: “There are a number of site constraints that needed to be managed as part of the build, to deliver the architectural aspirations of the design. Steel provides the design flexibility to manage these in an economic way when compared to other forms of construction. It also allows the structural design to respond to the client’s aspiration for open-plan office spaces.”

Creating these desired column-free and flexible office spaces, a series of Westok cellular beams spans between the building’s perimeter columns, forming each of the floors without any internal support. As well as forming the open-plan floor spaces, the cellular beams also accommodate the building’s services within their depth, thereby efficiently reducing the structure’s floor-to-ceiling heights. Kloeckner Metals UK Westok provided design support to Curtins, and Westok’s Technical Advisory Engineer on the scheme, James Way, commented: “Great to be working once again with Curtins and Evadx on another commercial development in Manchester. The cellular beam design solution provides a neat clear-span floorplate within the strict structural zone depth limits, and delivers considerable flexibility for service integration.”

The cellular beams also support metal decking and a concrete topping to form a composite flooring solution on each of the structure’s upper levels. The steel frame is stabilised by a combination of bracing and an insitu reinforced concrete core. Lateral and longitudinal forces are transferred through diaphragm action within the insitu composite slabs to the strategically placed vertical bracings and core.

There are a number of challenges associated with the project due to the confined nature of the site. This has impacted on the steelwork erection programme as well as the installation of the floors. “Ordinarily we would position our cranes and MEWPs outside of the footprint, but the building is bounded by existing structures on two sides and roads on the other two, which meant this wasn’t possible,” explains EvadX Contracts Manager Andrew Roberts.

“Consequently, we had to coordinate our steel erection with the metal decking and concrete floor contractor, whereby we erected half the structure up to sixth floor with our equipment positioned in the other half of the footprint. We then had to wait until the erected portion was concreted, so we could use the floors as a base for our MEWPs to erect the other half of the building.” This same working sequence was then repeated for the levels from sixth floor up to the uppermost roof elements.

The trusses were delivered to the project in small sections and assembled insitu

Two parallel trusses span a subterranean canal

Model showing the steel frame and the two parallel trusses supporting the staircase - on the left

Another project challenge is buried deep below the southern end of the site. Here, an old disused subterranean canal crosses the site slightly beyond the building’s footprint, but just below the point where an external staircase will be erected. As no staircase-supporting columns could be installed above the canal, the project team has designed two 14m-long × 4m-high trusses. These large steel elements, positioned at ground floor and connected to the slab’s rebar, support the southern tip of the building and a 4m-wide cantilevering steel-framed staircase tower from their top chords.

“The trusses transfer the stanchion loadings back to new foundations positioned within the basement footprint, away from the vaulted masonry arch of the existing subterranean listed canal structure,” says Ms Boroujerdi. “A number of solutions were explored, but the truss solution was favoured due the constraints of the site, architecture and to minimise spatial impact, as the truss chords and internal members are located within the make-up of the building’s cladding.”

The attached staircase has also required the entire southern gable end of the steel frame to be designed as one large braced Vierendeel truss. “Both trusses were trial erected at our North Wales fabrication yard to make sure they fitted together seamlessly on site. We then disassembled them and delivered the steelwork to site in small pieces of up to 6t. This allowed the steelwork to be transported and then lifted into place with the available craneage,” sums up Mr Roberts.

The office block is due to complete in October.

The design of nodes in major trusses

David Brown of the SCI comments.

Transfer trusses invariably carry high loading, leading to large members and complex connections - the trusses at the Granada Studios redevelopment are no exception. As can be seen, the truss was detailed to be bolted together on site, demanding a careful approach to the connections. The nodes themselves were welded in the workshop, with a continuous thick plate replacing the web in the chord members and forming the gusset for connection to the diagonals. In significant members such as these transfer trusses, slip is to be avoided – the unpainted faying surfaces can be seen, showing the site connections were completed with preloaded assemblies.

The connections to the gusset plates have perpendicular plates which are the same thickness as the flanges of the diagonals, which facilitates the use of internal and external cover plates. This has the advantage of doubling the number of friction planes which obviously helps reduce the number of bolts required and produces a more compact connection. The substitute flanges must be long enough (and the welds sufficiently capable) to transfer the load from the member into the gusset plate.

The members and cover plates must be verified when in tension – even if the connection is Category C (non-slip at ULS) the net cross section at bolt holes must be verified. In compression, the buckling resistance of the plates in compression must be verified. The longest buckling length is usually the spacing across the joint itself. Note 2 to Table 3.3 of BS EN 1993-1-8 provides advice when the check is required and the buckling length which is to be used in the design check.

Trusses like those at the Granada Studios redevelopment must be fabricated precisely if the erection and assembly is to proceed smoothly on site. These trusses were trial assembled in the workshop – the EvadX LinkedIn posts include many photographs of the fabrication of these trusses, showing the connection details, the trial assembly – and the considerable welding required. The site photos are also interesting, including one diagonal being located in position.

An alternative approach to the design of major truss nodes was covered in New Steel Construction, October 2019, where it was possible to turn the chords and internal members through 90°. The article considers a similar concept utilising relatively thick plates to form the node and completing bolted splice connections clear of the node.

| Architect | 3D Reid |

| Structural Engineer | Curtins |

| Steelwork Contractor | EvadX |

| Main Contractor | Bowmer + Kirkland |

| Main Client | Allied London |