Acoustic performance of walls

This article provides guidance on detailing of walls for acoustic performance. It shows the range of types of light steel wall constructions suitable for separating and internal walls. A wide range of construction possibilities exists and, therefore, only a sample of possible constructions is illustrated within the article. A review of the available light steel wall studs and wall linings for acoustic performance is presented.

The SCI has developed an acoustic performance prediction tool for separating floors and walls to assist designers and architects.

[top]Light steel wall studs

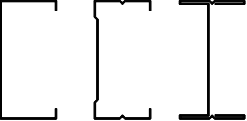

[top]‘C’ and ‘I’ Section studs

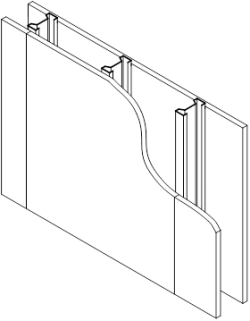

'C' and 'I' section cold formed steel studs are used as vertical elements in walls. Typical profiles are shown in the figure on the right. Sections are available in a range of widths, lengths and thicknesses depending on requirements for strength, height, impact resistance and sound insulation. Typical dimensions of a section are 70 to 100 mm deep and 0.9 to 1.6 mm thick. Light steel stud walls can be load bearing or non load bearing.

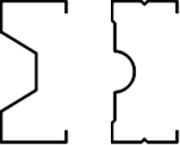

[top]Acoustic studs

Manufacturers produce acoustic studs which have unique characteristics for increased acoustic performance. The studs have specially developed profiles, particularly the web, which absorb sound energy and reduce sound transfer through walls. Acoustic studs can be used to upgrade the acoustic performance of wall systems. Typical cross sections of acoustic studs available are shown in the figure below. Sizes are similar to those for ‘C’ and ‘I’ section studs but the thickness is usually less. Acoustic studs are generally non load-bearing.

[top]Wall linings

There are many different types of gypsum-based boards which have been developed to have different properties suitable for different purposes. Gypsum-based boards fall into two main categories; plasterboards and fibre reinforced boards.

Generic descriptions of the different types of boards are provided below. However, boards from different manufacturers will have different physical properties and different performance characteristics, even though they may have been developed for similar uses. Therefore, substitution of boards should only be carried out with the agreement of the system supplier or an acoustic consultant.

Gypsum-based boards are suitable for lining light steel frame walls, partitions and also ceilings.

[top]Plasterboards

Conventional plasterboards consist of a pure gypsum core bonded between two paper liners. The composition of the gypsum core and the paper liners are varied and other materials are laminated to the boards to create a range of plasterboards with different performance characteristics. The different types of plasterboards are often colour coded for identification on site and are described below. In many cases manufacturers can combine different properties into one plasterboard product. Plasterboards properties are defined in BS EN 520: 2004[1].

Standard board

Standard board, i.e. conventional plasterboard without enhanced properties as described for the specialist board types below, is used for internal walls, ceilings and partitions, in both domestic and commercial premises.

Sound resistant board

Sound control board is a heavy duty board used where superior acoustic performance is required. It has a dense high purity gypsum core between two high quality paper liners.

Fire control board

Fire control board is used for the encasement of structural steelwork, lining walls, ceilings, shafts and partitions where high levels of fire resistance are required.

Fire control boards provide a higher degree of fire resistance than standard board by incorporating additives, such as glass fibre, within the gypsum core.

Moisture control board

Moisture control board is used in bathrooms, kitchens, domestic garages and other applications that require increased resistance to the effects of moisture and humidity. The gypsum plaster core and paper liners are treated with water repellent additives but it remains permeable to water vapour allowing the underlying structure to breathe. It is not suitable for areas of continuous wetting or high humidity conditions such as in swimming pools.

Thermal control board

Thermal control boards are a range of plasterboard thermal laminates. Plasterboard is bonded to different types of insulation to suit a variety of thermal requirements. Possible thermal laminates include expanded polystyrene, extruded polystyrene and phenolic foams.

Vapour control board

Vapour control board has a film bonded to one face, which acts as a vapour control layer and can also give improved thermal performance.

Impact resistant board

Impact resistant board is heavy duty plasterboard for use in active environments such as schools, hospitals and residential corridors. The increased impact resistance is provided by heavy duty paper facings and a higher density core.

[top]Gypsum fibre boards

Cellulose fibre reinforced gypsum boards

High performance boards are produced by combining gypsum with cellulose fibres from recycled paper. Cellulose fibre reinforced gypsum boards are suitable for lining all forms of walls, partitions and ceilings. Cellulose fibre reinforced gypsum board is heavier and stronger than plasterboard and has enhanced performance in terms of resistance to moisture, sound, fire and impact. The higher strength of the board is advantageous for supporting fixings, restraining light steel joists and studs and providing racking resistance.

Flooring products are manufactured using cellulose fibre reinforced gypsum boards bonded to insulation and isolation layers as appropriate.

Glass fibre reinforced gypsum boards

Glass fibre reinforced gypsum boards are also suitable for lining all forms of walls, partitions and ceilings. The board gives enhanced levels of fire and impact protection and offers increased levels of moisture performance compared to plasterboard. Boards can be supplied bonded to a foil-backed phenolic foam and integral vapour control layer.

[top]Board weights and densities

The weights and densities of the various types of boards suitable for wall linings are summarised in the table below.

| Board type | Thickness (mm) | Mass per unit area (kg/m2) |

Density (kg/m3) |

|---|---|---|---|

| Standard plasterboard | 9.5, 12.5, 15, 19 | 6.3 - 15.0 | 660 - 790 |

| Sound resistant plasterboard | 12.5, 15 | 10.2 - 13.1 | 820 - 870 |

| Fire control plasterboard | 12.5, 15 | 9.8 - 12.8 | 780 - 850 |

| Moisture control plasterboard | 12.5, 15 | 8.6 - 10.3 | 680 - 700 |

| Thermal control plasterboard+ | 18 – 65 | 6.0 - 9.0 | 140 - 330 |

| Vapour control plasterboard | 9.5, 15 | 6.3 - 9.8 | 650 - 660 |

| Impact resistant plasterboard | 12.5, 15 | 11.7 - 13.9 | 930 - 940 |

| Cellulose fibre reinforced | 10, 12.5, 15, 18 | 11.5 - 21.0 | 1200 |

| Glass fibre reinforced | 6 – 30 | 6 - 25.5 | 850 - 1000 |

Note:

+Properties are for the composite product (plasterboard and bonded insulation)

[top]Resilient bars

Resilient bars can be used to increase the sound insulation by absorbing vibrations.

These bars may be fixed between the light steel wall studs and the wall linings. Resilient bars are manufactured from light gauge steel (typically 0.5 mm thick); the sections are typically 16 mm deep.

[top]Separating walls

This section describes the range of light steel wall constructions suitable for separating and internal walls. There is a wide range of possible separating wall constructions, due to the permutations of type and thickness of stud, board and insulation that may be used. Therefore, the constructions shown represent only a sample of the possible constructions.

All expected acoustic performance values are indicative and provided that the walls are built correctly and their junctions are properly detailed and integrated with other elements, these examples should provide the quoted expected acoustic performance. Manufacturers’ literature, system suppliers and/or an acoustic consultant should be consulted for detailed specifications and more precise expected acoustic performance figures.

The following wall constructions are presented:

- Twin light steel frames (insulation between frames)

- Twin light steel frames (insulation between studs)

- Twin light steel frames for modular construction

- Single acoustic stud light steel frame

- Single light steel frame with resilient bars

- Staggered stud light steel frame.

When detailed in accordance with the Robust Details Handbook[2], the twin light steel frame walls (see following sections) are Robust Detail separating walls.

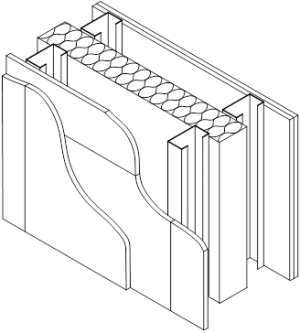

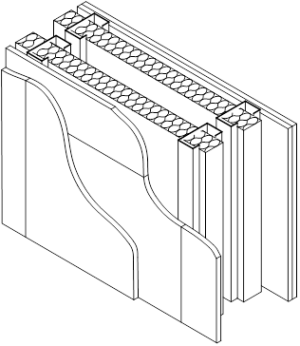

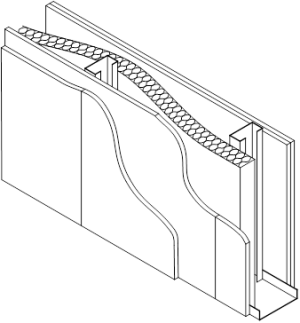

[top]Twin light steel frames (quilt between frames)

Studs

Studs are typically 50 to 100 mm deep and are usually ‘C’ or ‘I’ sections. The shape, size and spacing of the studs will depend on whether the wall is load-bearing or non load-bearing. 100 mm studs are typically used for load-bearing walls. This wall is a Robust Detail (E-WS-1) when specified to comply with the requirements given in the Robust Details Handbook[2].

Quilt

Mineral wool quilt placed in the cavity between the two frames is typically 50 to 100 mm thick and has a density between 10 and 60 kg/m3.

Boards

Two layers of gypsum-based board on each face with a minimum total mass per unit area of 22 kg/m2 per face. Typically this comprises two layers of 15 mm sound resistant or fire resistant plasterboard or two layers of 10 mm gypsum fibre board.

Construction thickness

The overall wall thickness is typically 250 to 300 mm.

Expected performance

Rw = 56 to 66 dB

DnT,w + Ctr = 45 to 56 dB

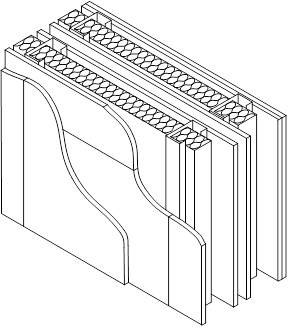

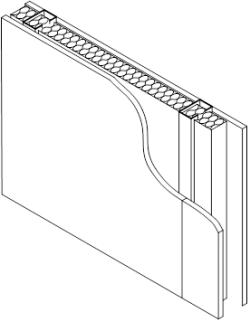

[top]Twin light steel frames (quilt between studs)

Studs

Studs are typically 50 to 100 mm deep and are usually ‘C’ or ‘I’ sections. The shape, size and spacing of the studs will depend on whether the wall is load-bearing or non load-bearing. 100 mm studs are typically used for load-bearing walls. This wall is a Robust Detail (E-WS-1) when specified to comply with the requirements given in the Robust Details Handbook[2].

Quilt

Mineral wool quilt is placed between the studs of each frame. Each layer is typically 50 to 75 mm thick and has a density between 10 and 60 kg/m3.

Boards

Two layers of gypsum-based board on each face with a minimum total mass per unit area of 22 kg/m2 per face. Typically this comprises two layers of 15 mm sound resistant or fire resistant plasterboard or two layers of 10 mm gypsum fibre board. The cavity between inner faces of the wall linings should be at least 200 mm.

Construction thickness

The overall wall thickness is typically 250 to 300 mm.

Expected performance

Rw = 56 to 66 dB

DnT,w + Ctr = 45 to 56 dB

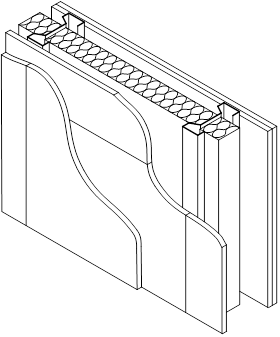

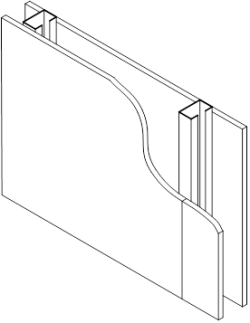

[top]Twin light steel frames for modular construction

Studs

Studs are typically 70 to 100 mm deep and are usually ‘C’ sections of 1.6 mm thickness. This wall is a Robust Detail (E-WS-3) when specified to comply with the requirements given in the Robust Details Handbook[2].

Quilt

Mineral wool quilt is placed between the studs of each frame. The quilt in each frame is typically 50 to 80 mm thick and has a density between 10 and 60 kg/m3.

Boards

Two layers of gypsum-based board on each room face with a minimum total mass per unit area of 22 kg/m2 per face. Typically this comprises two layers of 15 mm sound resistant or fire resistant plasterboard or two layers of 10 mm gypsum fibre board. A sheathing board is fixed to the other face of each stud frame. The sheathing board is generally OSB, plywood, cement particle board or alternatively a weather resistant gypsum-based board. The cavity between the two sheathing boards should be at least 40 mm.

Construction thickness

The overall wall thickness is typically 260 to 350 mm.

Expected performance

Rw = 57 to 69 dB

DnT,w + Ctr = 47 to 56 dB

[top]Single acoustic stud light steel frame

Studs

Specially designed acoustic studs used in separating walls are typically 90 to 150 mm deep. Acoustic studs are generally non load-bearing.

Quilt

Mineral wool quilt placed between the studs is typically 50 to 75 mm thick and has a density between 10 and 60 kg/m3.

Boards

Two layers of gypsum-based board on each face with a minimum total mass per unit area of 22 kg/m2 per face. Typically this comprises two layers of 15 mm sound resistant plasterboard or two layers of gypsum fibre board one 12.5 mm and one 10 mm.

Construction thickness

The overall construction thickness is typically 150 to 210 mm.

Expected performance

Rw = 56 to 61 dB

DnT,w + Ctr = 45 to 50 dB

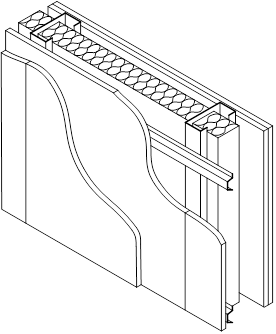

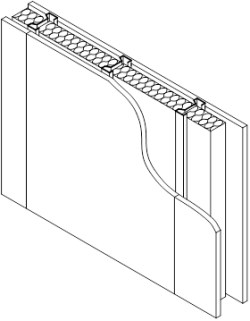

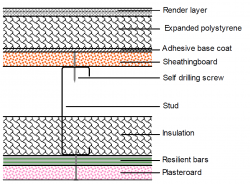

[top]Single light steel frame with resilient bars

Studs

Studs are typically 70 to 150 mm deep and are usually ‘C’ or ‘I’ sections. The shape, size and spacing of the studs will depend on whether the wall is load-bearing or non load-bearing. Resilient bars may be fixed to only one side of the studs (as shown) or to both sides for enhanced performance. Resilient bars are typically 17 mm deep.

Quilt

Mineral wool quilt placed between the studs is typically 50 to 75 mm thick and has a density between 10 and 60 kg/m3.

Boards

Two layers of gypsum-based board on each face with a minimum total mass per unit area of 22 kg/m2 per face. Typically this comprises two layers of 15 mm sound resistant or fire resistant plasterboard or two layers of 10 mm gypsum fibre board.

Construction thickness

The overall construction thickness is typically 140 to 220 mm.

Expected performance

Rw = 59 to 62 dB

DnT,w + Ctr = 47 to 51 dB

[top]Staggered stud light steel frame

Studs

Studs are typically 60 to 90 mm deep and are usually ‘C’ or ‘I’ sections. These are fixed inside top and bottom tracks which are wider than the stud and are fastened to alternate sides of tracks so that studs are staggered. Tracks are usually 90 to 150 mm wide.

Quilt

Mineral wool quilt placed between the studs is typically 25 to 50 mm thick and has a density between 10 and 60 kg/m3.

Boards

Two layers of gypsum-based board on each face with a minimum total mass per unit area of 22 kg/m2 per face. Typically this comprises two layers of 15 mm sound resistant plasterboard or two layers of gypsum fibre board, one 12.5 mm and one 10 mm.

Construction thickness

The overall construction thickness is typically 120 to 210 mm.

Expected performance

Rw = 57 to 63 dB

DnT,w + Ctr = 45 to 52 dB

[top]Internal walls

All the details shown below are suitable for internal walls. Manufacturers’ literature or system suppliers should be consulted for detailed specifications and expected acoustic performance.

All expected acoustic performance values are indicative and provided that the walls are built correctly and their junctions are properly detailed and integrated with other elements, these examples should provide the quoted expected acoustic performance.

The following wall constructions are presented:

- Single light steel frame (with quilt)

- Single light steel frame (without quilt)

- Single acoustic stud light steel frame (with quilt)

- Single acoustic stud light steel frame (without quilt).

Internal walls are not required to undergo on-site testing to demonstrate compliance with the noise insulation requirements of Approved Document E[3].

[top]Single light steel frame (with quilt)

Studs

Studs are typically 50 to 150 mm deep and are usually ‘C’ or ‘I’ sections.

Quilt

Mineral wool quilt placed between the studs is typically 25 to 50 mm thick and has a density between 10 and 45 kg/m3.

Boards

One layer of gypsum-based board on each face. This may be 12.5 or 15 mm thick standard wall board, sound resistant plasterboard or gypsum fibre board, depending on the required acoustic performance.

Construction thickness

The overall construction thickness is typically 75 to 175 mm.

Expected performance

Rw = 40 to 50 dB

[top]Single light steel frame (without quilt)

Studs

Studs are typically 50 to 150 mm deep and are usually ‘C’ or ‘I’ sections.

Quilt

There is no quilt in this wall construction.

Boards

One layer of gypsum-based board on each face. This may be 12.5 or 15 mm thick standard wall board, sound resistant plasterboard or gypsum fibre board, depending on the required acoustic performance.

Construction thickness

The overall construction thickness is typically 75 to 175 mm.

Expected performance

Rw = 34 to 43 dB

[top]Single acoustic stud light steel frame (with quilt)

Studs

Studs are typically 45 to 125 mm deep and are usually variations on ‘C’ sections.

Quilt

Mineral wool quilt placed between the studs is typically 25 to 50 mm thick and has a density between 10 and 25 kg/m3.

Boards

One layer of gypsum-based board on each face. This may be 12.5 or 15 mm thick standard wall board, sound resistant plasterboard or gypsum fibre board, depending on the required acoustic performance.

Construction thickness

The overall construction thickness is typically 75 to 150 mm.

Expected performance

Rw = 43 to 52 dB

[top]Single acoustic stud light steel frame (without quilt)

Studs

Studs are typically 45 to 125 mm deep and are usually variations on ‘C’ sections with specially designed profiles.

Quilt

There is no quilt in this wall construction.

Boards

One layer of gypsum-based board on each face. This may be 12.5 or 15 mm thick standard wall board, sound resistant plasterboard or gypsum fibre board, depending on the required acoustic performance.

Construction thickness

The overall construction thickness is typically 75 to 150 mm.

Expected performance

Rw = 39 to 43 dB

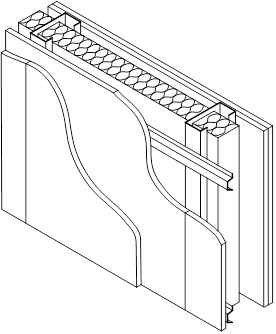

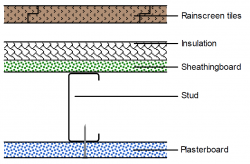

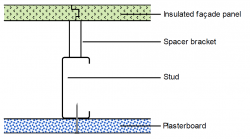

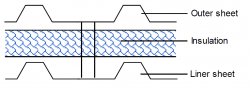

[top]External walls

For masonry walls, such as a 225 mm solid brick wall, a brick and block cavity wall or a brick-clad stud frame wall (timber or light gauge steel), the sound insulation performance of the façade will normally be such that the doors, windows, ventilators and, in some cases, the roof will dictate the overall sound insulation of the building envelope. Therefore, it is the specification and location of these items that is just as important as the wall construction.

Light gauge steel frame (or timber) walls with lightweight cladding normally provide a lower standard of sound insulation at low frequencies, where road traffic and aircraft often produce high levels of noise. This can result in low airborne sound insulation against these noise sources unless the cladding system has sufficient low frequency sound insulation. The airborne sound insulation can be assessed from laboratory measurements carried out according to BS EN ISO 10140-2[4].

For heated buildings with properly specified doors, windows and ventilators, the thermal insulation requirements are often the governing design criteria for external walls rather than the acoustic insulation performance.

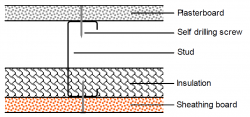

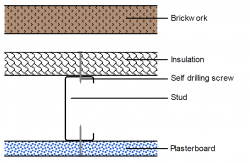

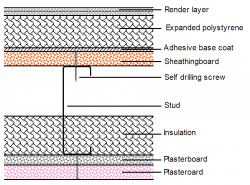

Indicative acoustic performance values for various construction arrangements are tabulated below.

| Description | Rw |

|---|---|

| Solid wall (225 mm brickwork and plaster) | ~ 55 dB |

| Solid light weight block (100 mm block and plaster) | ~ 43 dB |

| Basic light gauge steel wall | ~ 45 dB |

| Light gauge steel wall with brickwork outer leaf | ~ 60 dB |

| Rendered light gauge steel wall | ~ 49 dB |

| Rendered light gauge steel wall with resilient bars | ~ 53 dB |

| Ventilated rainscreen with light gauge steel wall | ~ 45 dB |

| Insulated façade panel with light gauge steel wall | ~ 44 dB |

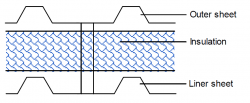

| Built-up cladding system (120 mm mineral wool) | ~ 40 dB |

| Built-up cladding system (180 mm mineral wool) | ~ 45 dB |

The exact acoustic performance of the external wall system is dependant on the specification of the products used. Where higher levels of acoustic insulation are required the internal plasterboard lining can be upgraded, e.g. by using sound insulating boards rather standard wall board or by increasing the number of layers.

The arrangements described within the above table are illustrated in the following figures.

- External wall construction

[top]References

- ↑ BS EN 520:2004+A1:2009 Gypsum plasterboards. Definitions, requirements and test methods. BSI

- ↑ 2.0 2.1 2.2 2.3 Robust Details Handbook, Robust Details Limited, 2014.

- ↑ Approved Document E (Resistance to the passage of sound) 2003 Edition incorporating 2004, 2010, 2013 and 2015 amendments. Ministry of Housing, Communities & Local Government

- ↑ BS EN ISO 10140-2:2021 Acoustics. Laboratory measurement of sound insulation of building elements. Measurement of airborne sound insulation. BSI

[top]Further reading

- Carl Hopkins. Sound insulation. Elsevier, Butterworth-Heinemann, 2007.

- M.W. Simons & J. R. Waters. Sound Control in Buildings. A guide to Part E of the Building Regulations. Blackwell publishing, 2004.

- Acoustic performance of pre-finished steel cladding systems

- Technical paper No. 8. Acoustic Guide for Metal Roof and Wall Cladding Systems, MCRMA

[top]Resources

- SCI P372 Acoustic Detailing for Steel Construction

- SCI P371 Acoustic performance – Case Studies

- SCI P320 Acoustic performance of light steel framed systems

- SCI Advisory Desk Note AD 287. Acoustic detailing: Steel columns in masonry separating walls

- SCI Acoustic performance prediction tool for separating floors and walls

[top]See also

- Introduction to acoustics

- Acoustics regulations

- Acoustic performance of floors

- Junction details for acoustic performance

- Integration of elements for acoustic performance

- Infill walling

- Modular construction

- Thermal performance

- Structural fire resistance requirements

- Fire protecting structural steelwork