Fire damage assessment of hot rolled structural steelwork

The assessment of fire damaged hot rolled structural steel is an area in which many engineers and architects have little practical experience. On many occasions fire affected steelwork shows little or no distortion resulting in considerable uncertainty regarding its re-usability. This is particularly true in situations where fire has resulted in some parts of the structure exhibiting little or no damage alongside areas where considerable damage and distortion are clearly visible.

Comprehensive information on the subject was published in the 1980s in Reinstatement of Fire Damaged Iron and Steel Framed Structures[1]. The following text is a summary of some of the relevant information in that document.

[top]Reasons for fire damage

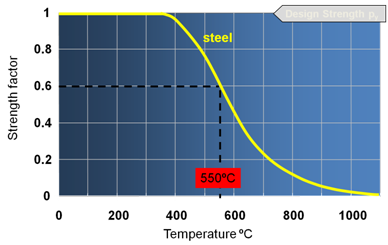

All materials weaken with increasing temperature and steel is no exception. Strength loss for steel is generally accepted to begin at about 300°C and increases rapidly after 400°C. By 550°C steel retains approximately 60% of its room temperature yield strength, and 45% of its stiffness. At high temperatures, steel is also subjected to significant thermal elongation, which may lead to adverse impacts, especially if it is restrained. It follows therefore that one would expect that structural steelwork which has been subjected to high temperatures would exhibit signs of this in the form of distortion and buckling.

[top]Behaviour of BS EN 10025[2] grade S275 steel

A grade S275, hot rolled structural steel section, subjected to fire conditions which causes its temperature to rise above 600°C, may suffer some deterioration in residual properties on cooling. In no situation however, irrespective of the fire temperature, will the room temperature yield stress or the tensile strength fall further than 10% below their original values. Thus, where it can be safely concluded that the steel members will be utilised to less than 90% of their maximum load bearing capacity or that any loss in strength will not bring the properties below the guaranteed minimum, replacement should not be considered necessary providing the member satisfies all other engineering requirements (e.g. straightness).

[top]Behaviour of BS EN 10025[2] grade S355 steel

Grade S355, hot rolled structural steel also suffers losses in residual yield and tensile strength when subjected to temperature over 600°C in fire. High strength steels, of which Grade S355 is typical, obtain their characteristics as the result of the addition of strengthening elements, typically vanadium and niobium. At high temperatures these elements tend to precipitate out of the matrix creating a coarse distribution. As a result the reduction in yield strength at room temperature after the steel has been heated to temperatures above 600°C, may be up to 25%.

[top]Connections and foundations

The tensile strength reduction for grade 4.6 bolts is similar to that for grade S275 steel. For grade 8.8 bolts, which are heat treated in manufacture, the residual strength reduction is more marked if the material temperature has exceeded 450°C. The residual strength of these bolts falls to 80% and 60% after reaching temperatures of 600°C and 800°C respectively. To err on the side of caution it is recommended that bolts should be replaced if they show any sign of having been heated e.g. blistered paint, smooth grey scaled surface.

Contraction of heated members after the fire can cause distortion of connections. When carrying out an inspection of a fire damaged building it is recommended that special care is taken in inspecting the connections for cracking of welds, end plate damage, bolt failure etc. A number of bolts should be removed to inspect for distortion. Similar care should be taken when inspecting foundations for bolt failure, concrete cracking etc.

[top]Re-use of fire damaged steel

An often quoted general rule for fire affected hot rolled structural steels is that if the steel is straight and there are no obvious distortions then it is probably still fit for use. At 600°C the yield strength and stiffness of steel is equal to about 40% and 30% respectively of their room temperature values; it follows therefore that any steel still remaining straight after the fire and which had been carrying an appreciable load was probably not heated beyond 600°C, will not have undergone any metallurgical changes and will probably be fit for re-use.

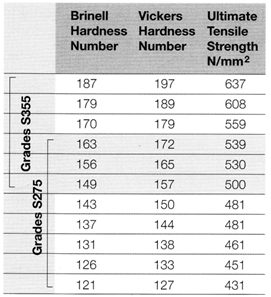

However, it is recommended that, in all cases, hardness tests should be carried out. For grade S275 steel, if the ultimate tensile strength resulting from the tests is within the range specified in the table, then the steel is probably reusable. For grade S355 steel additional tensile test coupons should be taken from fire affected high strength steel members when hardness tests show that:

- there is more than 10% difference in hardness compared to non-fire affected steelwork, or

- hardness test results indicate that the strength is within 10% of the specified minimum.

Where deflections are visible, general guidelines on the maximum permissible levels of deflection to ensure satisfactory performance are difficult to specify. The amount of deflection or distortion must be checked so that its effect under load can be calculated to ensure that the functioning of the structure is not impaired. Therefore every building should be considered as a separate case and the structural engineer involved in the reinstatement exercise must decide what level is acceptable to satisfy the relevant Codes.

[top]References

- ↑ Kirby B.R. et al. (1986) The reinstatement of fire damaged steel and iron framed structures, British Steel Corporation Swinden Laboratories

- ↑ Jump up to: 2.0 2.1 BS EN 10025-1:2004 Hot rolled products of structural steels. General technical delivery conditions. BSI

[top]Resources

[top]Further reading

- Ingham, J: Forensic engineering of fire-damaged structures. Proceedings of the Institute of Civil Engineers. Civil Engineering 162. May 2009. Pages 12–17

- Maraeas, C; Fasoulakis, Z; Tsavdaridis, K: Post-fire assessment and reinstatement of steel structures. Journal of Structural Fire Engineering, Vol 8 No. 2, 2017